Description

Key Technical Specifications

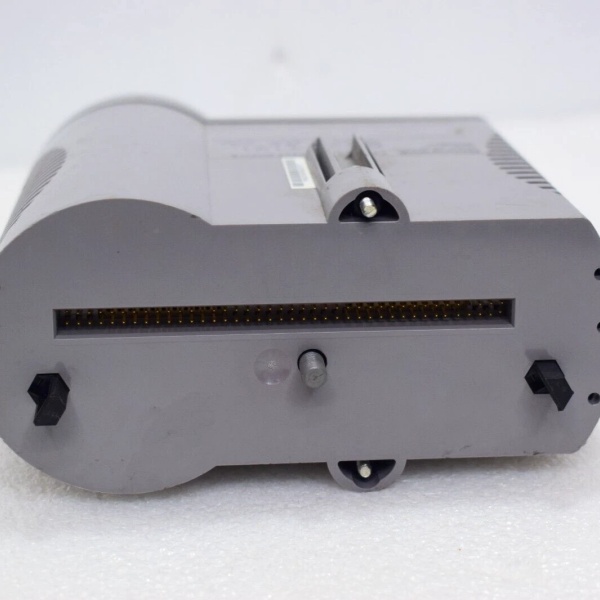

- Model Number: CC-PSP401

- Manufacturer: Honeywell Process Solutions

- Input Voltage Range: 100–240VAC (50/60Hz), wide-range input for global compatibility

- Output Voltage: 24VDC (regulated, ±2% tolerance)

- Output Current: 10A total (5A per redundant output channel)

- Redundancy Mode: N+1 (supports up to 2 modules per I/O rack for full redundancy)

- Hot-Swap Capability: Yes (supports module replacement without I/O rack shutdown)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Enclosure Rating: IP20 (rack-mounted for control cabinet installation)

- Certifications: UL 508, CSA C22.2 No. 142, CE, ATEX Zone 2 compliant

- Diagnostic Capabilities: Input voltage loss, output overcurrent, output undervoltage, module overheating, redundancy status monitoring

Honeywell CC-PFB801

Field Application & Problem Solved

In refineries, chemical plants, and power generation facilities running Experion PKS, the single biggest cause of unplanned I/O rack downtime is power supply failure. Legacy non-redundant power supplies take entire racks offline when they fail—this disconnects dozens of sensors and actuators, triggering process upsets or full shutdowns that cost plants tens of thousands of dollars per hour. The CC-PSP401 solves this with N+1 redundancy support: install two modules in an I/O rack, and if one fails, the other seamlessly takes over 100% of the load without disrupting I/O communication.

You’ll find this module in every safety-critical Experion PKS I/O rack: powering analog input modules on reactor temperature loops, digital output modules on ESD valve control systems, and fieldbus interface modules on pump skid networks. Its core value is reliability— the wide 100–240VAC input range handles voltage fluctuations common in industrial power grids, and the regulated 24VDC output ensures I/O modules get stable power, eliminating signal drift or false faults caused by voltage spikes. Unlike cheap aftermarket power supplies, it’s designed to withstand the vibration and EMI of industrial environments, so it doesn’t fail prematurely.

Another critical problem it addresses is hot-swap capability. During planned turnarounds or unplanned module failures, you can replace the CC-PSP401 without shutting down the I/O rack—this is a game-changer for continuous processes like natural gas liquefaction, where even a 5-minute rack shutdown causes product quality issues or production losses. Its built-in diagnostics also eliminate guesswork: the module reports power health directly to the Experion PKS HMI, so you can proactively replace a failing module before it takes down the rack.

Installation & Maintenance Pitfalls (Expert Tips)

Redundancy Requires Proper Module Pairing

Rookies often mix CC-PSP401 modules with older or incompatible power supply models in the same I/O rack, thinking “any 24VDC supply works.” Wrong—only identical CC-PSP401 modules can provide true N+1 redundancy. Mixing models causes the rack to detect a “redundancy mismatch” fault, and the modules won’t share the load. Always use two identical CC-PSP401 modules for redundancy, and confirm they’re running the same firmware version via the Experion PKS Configuration Studio. I’ve fixed a refinery’s ESD rack that was throwing redundancy faults— the issue was one CC-PSP401 and one obsolete CC-PSP300 module. Swapping the old module solved the problem instantly.

Airflow Clearance Is Non-Negotiable

The CC-PSP401 generates heat under full load, and it relies on front-to-back airflow in the I/O rack to stay cool. A common mistake is blocking the module’s front vents with cable bundles or leaving the rack’s rear cover off—this causes the module to overheat and trigger a shutdown. Maintain a minimum 2-inch clearance in front of the module and ensure the rack’s cooling fans are operational. During summer months, check the module’s temperature via the HMI diagnostic screen—if it’s running above 55°C, add auxiliary cooling to the control cabinet. Overheating is the #1 cause of premature CC-PSP401 failures in the field.

Don’t Skip Input Power Polarity Checks

The module’s AC input is not polarity-sensitive, but the wiring terminals are labeled for phase, neutral, and ground—ignoring these labels can lead to ground faults or power surges. Always connect phase to L1, neutral to N, and ground to the dedicated PE terminal. Never use the neutral wire as a ground—this creates a floating ground that damages the module’s internal regulation circuit. During installation, use a multimeter to verify phase and neutral before powering on the module—this takes 2 minutes and saves hours of troubleshooting later.

Diagnostic Alerts Are Not “False Positives”—Act On Them

Techs often dismiss the CC-PSP401’s undervoltage or overcurrent alerts as “power grid noise,” but these alerts almost always indicate a real issue. An undervoltage alert could mean the plant’s AC power is fluctuating (a sign of a failing transformer), while an overcurrent alert could mean an I/O module in the rack has a short circuit. Ignoring these alerts leads to unplanned failures: I’ve seen a chemical plant’s reactor control rack go offline because they ignored an overcurrent alert from the CC-PSP401— the root cause was a shorted analog output module that fried the power supply. Set up HMI alarms for all power diagnostics and require maintenance to investigate every alert within 24 hours.

Honeywell CC-PFB801

Technical Deep Dive & Overview

The Honeywell CC-PSP401 is a dedicated redundant power supply module designed for Experion PKS C-Series I/O racks, with a focus on high availability and diagnostic visibility. At its core, it uses a switch-mode power conversion circuit that converts 100–240VAC input to regulated 24VDC output— this switch-mode design is efficient (85%+ efficiency at full load) and handles voltage fluctuations better than linear power supplies. The module’s dual 5A output channels are designed for N+1 redundancy: when two modules are installed in a rack, they share the load equally, and if one fails, the other module ramps up to 10A output to carry the entire rack’s load.

The module’s hot-swap capability is enabled by a built-in backplane power connector that maintains power to the rack while the module is removed. It also has a front-panel status LED that shows power health (green = normal, red = fault, amber = redundancy loss), so you can quickly diagnose issues without opening the control cabinet. The diagnostic engine continuously monitors input voltage, output current, module temperature, and redundancy status, sending real-time data to the Experion PKS controller via the I/O rack backplane.

Unlike aftermarket power supplies, the CC-PSP401 is fully integrated with Experion PKS— it doesn’t require external monitoring tools, and all diagnostics are displayed natively on the HMI. Its IP20 rating means it’s meant for indoor control cabinet installation; if you need to mount it in a dusty or humid area, pair it with a NEMA 4X enclosure with forced air cooling. In the field, this module’s strength is its simplicity and durability— no moving parts, robust EMI shielding, and redundant design that eliminates single-point power failures. With proper installation (clear airflow, correct redundancy pairing, grounded wiring) and proactive maintenance (acting on diagnostic alerts), it will run for 8–10 years without unplanned downtime, making it the backbone of reliable Experion PKS I/O rack power.