Description

Key Technical Specifications

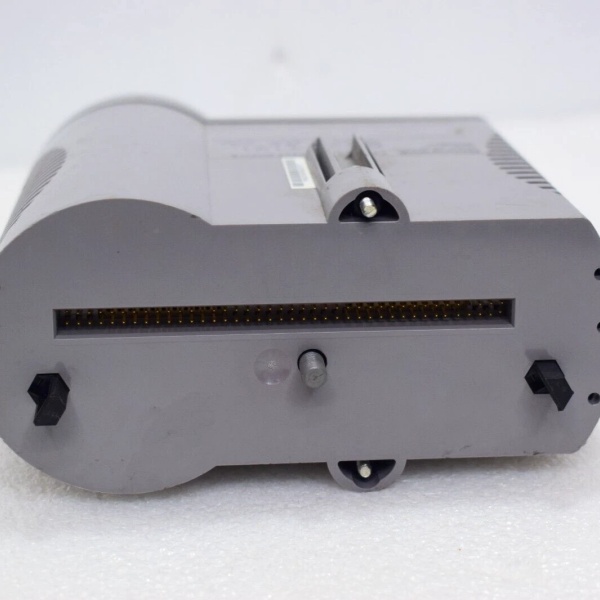

- Model Number: CC-PFB801

- Manufacturer: Honeywell Process Solutions

- Fieldbus Protocol: PROFIBUS DP (EN 50170 standard, Slave mode only)

- Max Baud Rate: 12 Mbps (auto-negotiates with master; supports 9.6 kbps–12 Mbps)

- Power Supply: 24VDC (18–32VDC range), dual redundant inputs, 0.5A max per input

- I/O Data Capacity: Up to 244 bytes input, 244 bytes output per module

- Hot-Swap Capability: Yes (supports replacement without Experion PKS controller shutdown)

- Isolation Rating: 500V AC (fieldbus port to backplane; 1-minute dielectric test)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Enclosure Rating: IP20 (rack-mounted for control cabinet installation)

- Certifications: UL 508, CSA C22.2 No. 142, CE, ATEX Zone 2 compliant

- Diagnostic Outputs: Real-time fault reporting (port errors, power loss, device disconnections) to Experion PKS HMI

Honeywell CC-PFB801

Field Application & Problem Solved

In refineries, chemical plants, and power generation facilities running Experion PKS, the biggest integration headache is connecting legacy PROFIBUS DP field devices (like Siemens VFDs or Endress+Hauser flow transmitters) to the DCS without adding costly gateways. Traditional gateways introduce latency and single points of failure—if the gateway goes down, all connected devices drop off the network. The CC-PFB801 solves this by acting as a native PROFIBUS DP slave module for the Experion PKS system, eliminating gateways and cutting down on network complexity.

You’ll find this module in every Experion PKS installation with a mix of Honeywell and third-party devices: linking VFDs on pump skids to the DCS, integrating analytical instruments on crude distillation units, and connecting motor starters on boiler feedwater systems. Its core value is low-latency data transfer—12 Mbps baud rate ensures real-time control signals reach actuators before process variables drift outside setpoints. Unlike gateways, it doesn’t require separate configuration software; all setup is done via the Experion PKS Configuration Studio, which reduces training time for maintenance techs.

Another critical problem it addresses is redundant power compatibility. In continuous processes like natural gas processing, a single power failure can take down an entire production line. The CC-PFB801’s dual 24VDC inputs let you connect it to two independent power supplies, ensuring the module stays online even if one supply fails. I’ve seen this module keep a polymer plant running through a utility power glitch that took out half the control cabinet’s power— the redundant input kicked in before the operator noticed a blip.

Installation & Maintenance Pitfalls (Expert Tips)

PROFIBUS Termination Resistors Are Mandatory

Rookies often forget to enable the built-in 120Ω termination resistor on the CC-PFB801 when it’s the last device on the PROFIBUS segment. This causes signal reflections, leading to intermittent communication drops or device disconnections. Check the module’s DIP switch settings—flip the termination switch to “ON” if it’s the end node; leave it “OFF” for middle nodes. I’ve fixed a refinery’s pump control loop that was dropping offline every 2 hours— the issue was a missing termination resistor on the CC-PFB801. A 2-second switch flip solved the problem.

Baud Rate Must Match the Entire PROFIBUS Segment

The module auto-negotiates baud rate, but it can’t fix a mismatch between the PROFIBUS master and other slaves. A common mistake is setting the master to 12 Mbps while a legacy transmitter only supports 1.5 Mbps— this crashes the entire segment. Always set the segment baud rate to the lowest supported speed of any device on the network. During commissioning, use a PROFIBUS scanner to verify baud rate consistency across all devices before connecting the CC-PFB801 to the DCS.

Redundant Power Inputs Need Separate Grounds

Connecting both redundant power inputs to the same ground bus creates a ground loop, which introduces noise into the PROFIBUS signal. This shows up as “flickering” device statuses on the HMI or random communication timeouts. Run each power input to a separate ground bus bar in the control cabinet— isolate the module’s power grounds from VFD or motor grounds to avoid noise contamination. This is a cheap fix that saves hours of troubleshooting.

Don’t Skip Firmware Updates for Third-Party Devices

The CC-PFB801 is rock-solid, but it can’t communicate with PROFIBUS devices running outdated firmware. I’ve seen a plant struggle to connect a new VFD to the module— the issue was the VFD’s firmware, which had a known PROFIBUS compatibility bug. Always update third-party devices to the latest firmware before integrating them with the CC-PFB801. Check Honeywell’s compatibility matrix for the module— it lists the minimum firmware versions for common devices like VFDs and transmitters.

Honeywell CC-PFB801

Technical Deep Dive & Overview

The Honeywell CC-PFB801 is a dedicated PROFIBUS DP slave module designed to bridge third-party field devices and the Experion PKS DCS, with no intermediate gateways required. At its core, it uses a PROFIBUS DP controller chip that handles all low-level protocol communication— this chip converts PROFIBUS data frames into the Experion PKS backplane protocol, ensuring seamless data transfer between the DCS and field devices. The module’s 244-byte input/output capacity is more than enough for most industrial applications, supporting up to 30 discrete inputs/outputs or 10 analog signals per module.

The dual redundant power inputs are fed into a built-in power management circuit that automatically switches to the secondary supply if the primary fails— switchover time is less than 1ms, so there’s no disruption to communication. The module’s diagnostic engine continuously monitors the PROFIBUS port for errors (e.g., cable faults, device timeouts) and sends real-time alerts to the Experion PKS HMI, letting techs troubleshoot without opening the control cabinet.

Unlike gateway-based solutions, the CC-PFB801 is hot-swappable— you can pull it from the I/O rack and replace it while the controller is running, as long as you enable the hot-swap setting in the Configuration Studio first. The module’s IP20 rating means it’s meant for indoor control cabinet installation; if you need to mount it in a hazardous area, pair it with a NEMA 4X enclosure. In the field, this module’s strength is its simplicity— no complex programming, no separate configuration tools, just plug-and-play integration that works day in and day out. With proper installation and firmware management, it will run for 7–10 years without unplanned downtime, making it a staple in mixed-vendor industrial control systems.