Description

Key Technical Specifications

- Communication Performance: It adopts carrier modulation technology to realize long-distance communication between devices, which is particularly suitable for occasions with serious electromagnetic interference. The data transmission speed can reach up to 10 Mbps, and it supports RS – 485 interface, which can form a multi-drop network, allowing multiple devices to communicate through a single cable. The standard RJ45 connector is adopted for convenient wiring and connection.

- Power & Energy Consumption: The operating voltage is mostly 24VDC, and there are also records of 12VDC versions. Its power consumption is less than 1W, which is quite energy-efficient, helping to reduce the overall operating cost of the industrial control system. In addition, the output frequency can adapt to 50/60Hz power grids in different regions.

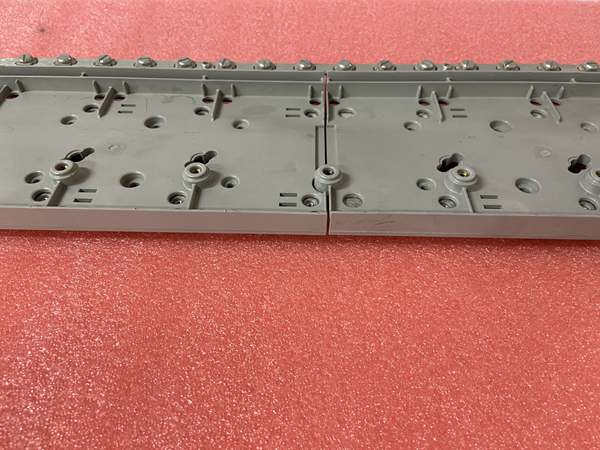

- Physical & Installation Parameters: The shape is compact, and there are slight differences in size data from different sources. A common specification is 120mm×70mm×20mm, and another record is 150×100×75mm. The weight ranges from 0.1kg – 3kg due to different configurations and packaging. The lightweight and small-size design facilitates installation in limited control cabinet spaces.

- Environmental Adaptability: It has excellent adaptability to harsh industrial environments. The operating temperature range can reach – 40°F to +185°F (equivalent to about – 40°C to +85°C), and some sources also record a range of – 5°C to 95°C. It can maintain stable operation in high – interference, high – temperature and other harsh working conditions.

Honeywell CC-MCAR01

Field Application & Problem Solved

It solves multiple key pain points in industrial control. Firstly, it addresses the problem of unstable signal transmission in harsh environments. Traditional communication modules are prone to signal loss or distortion under strong electromagnetic interference in industrial sites, while this module relies on carrier signal technology to maintain stable transmission. Secondly, it solves the difficulty of connecting remote equipment. In large – scale industrial sites such as water treatment plants, equipment is scattered. This module realizes long-distance communication without complicated wiring, reducing construction and maintenance costs. Moreover, its electrical circuit isolation function avoids mutual interference between different loops, preventing system failures caused by loop faults.

Honeywell CC-MCAR01

Installation & Maintenance Pitfalls (Expert Tips)

- Confirm Interface Matching During Wiring: The module is equipped with an RS – 485 interface and an RJ45 connector. When connecting with controllers, sensors and other devices, it is necessary to confirm the interface type and signal standard of the connected equipment. Mismatched interfaces will lead to communication failure. It is recommended to use dedicated communication cables and check the cable continuity with a multimeter before installation.

- Pay Attention to Voltage Matching: There are differences in the operating voltage of different versions of the module. Before power – on, confirm that the power supply voltage matches the module’s rated voltage. Using a voltage that exceeds the rated value will burn out the internal components, while an insufficient voltage will result in weak transmission signals and frequent disconnections. It is advisable to configure a regulated power supply to ensure voltage stability.

- Avoid Installation in Extreme Environmental Zones: Although it has a wide operating temperature range, it should not be installed directly in areas with direct sunlight, oil pollution or heavy moisture, such as near the exhaust port of industrial boilers or the liquid level of storage tanks. These environments will accelerate the aging of the module’s shell and internal circuits. It is recommended to install it in a sealed control cabinet and add a heat dissipation device if necessary.

- Regularly Detect Transmission Stability: During daily maintenance, use industrial communication detectors to check the module’s data transmission speed and error rate. If phenomena such as delayed signal transmission or increased error rate are found, timely check whether the module’s antenna (if equipped) is loose, whether the wiring is corroded, and clean or replace the parts in time. Regular inspection can prevent sudden communication interruption from affecting industrial production.