Description

Key Technical Specifications

- Input & Compatibility: It is a 16-point high-level analog input module that mainly supports 4 – 20mA DC analog signals. There are two versions: one supports both high-level analog and HART inputs, and the other only supports high-level analog inputs without HART function. The HART version can utilize HART data for device status monitoring, configuration, and can also take secondary and tertiary variables in HART data as process control variables.

- Installation & Physical Parameters: It adopts a horizontal installation method and is suitable for C300/CF9 IOTA configurations. Its size is 2.2 cm × 12.4 cm × 12.6 cm and it weighs only 0.1 kg. For non-redundant applications, it is installed on a 6-inch IOTA; for redundant applications, it needs to be matched with a 12-inch IOTA, which helps save the installation space of the control cabinet.

- Environmental Adaptability: It can operate stably in the temperature range of -20°C to +55°C. This temperature adaptability allows it to cope with the temperature changes in most industrial workshops and control rooms without being easily affected by the environment and causing signal acquisition abnormalities.

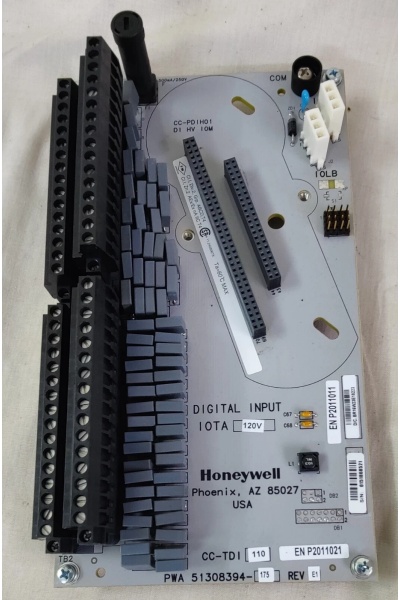

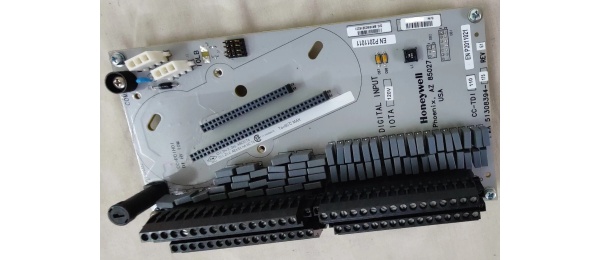

Honeywell CC-TDI220

Field Application & Problem Solved

In industrial scenarios, it solves multiple practical problems. Firstly, it addresses the compatibility issue of HART devices. Traditional analog modules cannot interact with HART devices. The corresponding version of this module enables two-way communication with HART transmitters, eliminating the need for additional HART communication modules and reducing system configuration costs. Secondly, the support for redundant installation solves the problem of system downtime caused by module failure in critical processes. In addition, its compact design solves the problem of limited installation space in control cabinets, especially for projects that need to expand the number of detection points on the basis of the original system.

Honeywell CC-TDI220

Installation & Maintenance Pitfalls (Expert Tips)

- Confirm Module Version Before Matching Devices: Since there are versions with and without HART function, when connecting to HART transmitters, it is necessary to confirm that the module is the HART-compatible version. Using the non-HART version will result in the inability to read HART-related data, and it will also fail to realize functions such as remote configuration of transmitters. It is recommended to check the module label and product manual to confirm the version before installation.

- Match IOTA Size According to Installation Type: The module’s IOTA size differs between redundant and non-redundant installations. Non-redundant applications require a 6-inch IOTA, while redundant applications need a 12-inch IOTA. Choosing the wrong IOTA size will lead to installation failure or unstable operation. It is advisable to determine the installation type first and then select the matching accessories.

- Pay Attention to Wiring Contact Reliability: The module relies on stable wiring to collect signals. It adopts a 9-port FTE control firewall input-output termination assembly. Among them, 8 ports are used to connect FTE cables of in-cabinet controllers, and the 9th port is used for uplink to the FTE monitoring network. During wiring, ensure that the cable connections are firm. Loose connections will cause signal loss or fluctuation. It is recommended to use professional wiring tools and conduct continuity tests after wiring.

- Regularly Check Module Operation Status: Although the module has high reliability, long-term operation may be affected by electromagnetic interference and circuit aging. For the HART version, it is necessary to regularly check whether the HART data transmission is smooth; for the non-HART version, verify the accuracy of analog signal acquisition. It is recommended to conduct a comprehensive inspection every six months. For modules in harsh working environments, shorten the inspection cycle to ensure the stability of the industrial control system.