Description

Key Technical Specifications

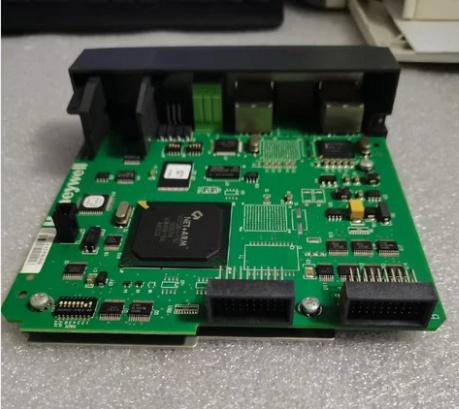

- Slot Configuration: It is equipped with 12 I/O slots, which can be flexibly matched with multiple types of HC900 series I/O modules. These include 16 – channel universal galvanically isolated I/O modules, 8 – point universal analog input modules, 4 – point galvanically isolated analog output modules, 8 – point relay output modules, etc. This modular matching method can meet the personalized control needs of different industrial processes.

- Power Supply Feature: The product adopts a non – redundant power supply design. It should be noted that it is different from the 900R12R – 0300 model with redundant power supply. When used in scenarios with high requirements for continuous operation, it is recommended to configure an external backup power supply to avoid system suspension caused by power supply failure.

- Environmental Adaptability: It has excellent adaptability to harsh industrial environments. The external operating temperature range can reach – 40°C to 70°C, which enables it to operate stably in extreme environments such as high – cold outdoor industrial sites and high – temperature workshops, and is not easily affected by temperature fluctuations.

- Physical & Quality Assurance: The product is supplied as a complete assembly in a carton package. Referring to the similar models of the same series, it has the characteristics of compact structure, which is convenient for installation in standard control cabinets. Meanwhile, the 100% finished product inspection before leaving the factory ensures the stability of its quality and performance.

Honeywell 900R12-0300

Field Application & Problem Solved

In actual industrial scenarios, the decentralized distribution of various detection and control modules often leads to problems such as messy wiring, difficult maintenance, and unstable data transmission. The 900R12 – 0300 solves these pain points well. It can centrally install various I/O modules required for the production process on one rack. For example, in a chemical production line, analog input modules for collecting temperature and pressure signals, digital output modules for controlling valve switching, and relay output modules for driving pumps can be integrated on this rack. This not only makes the on – site wiring neat and standardized, but also realizes the centralized transmission of data between modules and the controller, improving the efficiency and stability of the control system.

Honeywell 900R12-0300

Installation & Maintenance Notes

- Match Modules Correctly: When installing I/O modules, confirm that the modules are of the HC900 series. Before inserting the modules, check whether the pins of the modules are intact and free of oxidation. Insert them smoothly during installation to avoid damaging the pins and the slot interfaces of the rack.

- Pay Attention to Power Supply Configuration: Since the product does not have a redundant power supply, for key production lines, an external uninterruptible power supply (UPS) should be configured. This can prevent data loss or equipment misoperation caused by sudden power outages and ensure the continuity of the production process.

- Regular Inspection of Interfaces: During daily maintenance, regularly check the connection tightness of each module and the rack slot. Dust and dirt in the slots should be cleaned in time. In humid or dusty environments, it is necessary to shorten the inspection cycle to avoid poor contact caused by dust accumulation or moisture corrosion.

- Distinguish from Similar Models: It is easy to be confused with the redundant power model 900R12R – 0300. When purchasing and replacing, strictly confirm the model number. If the redundant power supply function is mistakenly required in the application scenario, using the 900R12 – 0300 will bring potential risks to the system operation.