Description

Key Technical Specifications

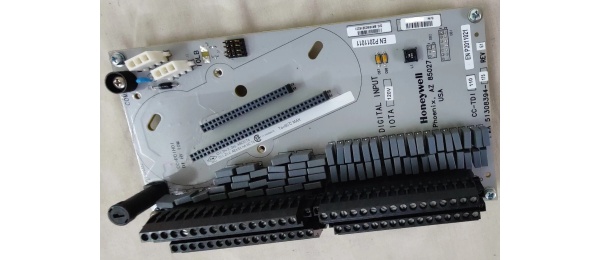

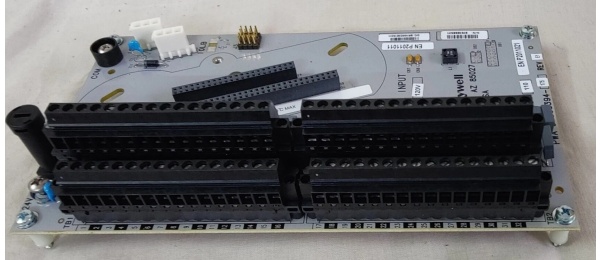

- Model Number: 8C-TDIL01

- Manufacturer: Honeywell Process Solutions

- Input Channels: 16 independent 24VDC sink-type digital inputs

- Input Voltage Range: 18–32VDC (operational); High = >15VDC, Low = <9VDC

- Input Current: 4mA @ 24VDC (nominal)

- Power Supply: Dual redundant 24VDC inputs, 0.6A max total current draw

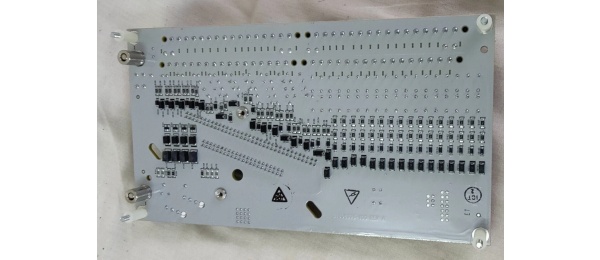

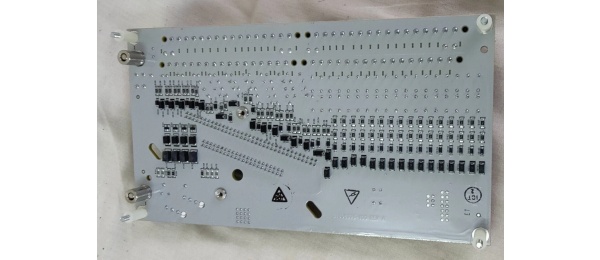

- Isolation Rating: 2500V AC (field-to-logic; 1-minute dielectric test); 500V AC (channel-to-channel)

- Hot-Swap Capability: Yes (supports module replacement without HC900 controller shutdown)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Enclosure Rating: IP20 (rack-mounted for control cabinet installation)

- Certifications: UL 508, CSA C22.2 No. 142, CE, ATEX Zone 2 compliant

- Diagnostic Capabilities: Per-channel open-circuit, short-circuit, and under-voltage detection

Honeywell CC-TDI220

Field Application & Problem Solved

In water treatment plants, refineries, and food and beverage facilities running HC900 hybrid control systems, the biggest pain point with digital input modules is channel failures that go undetected until a process upset occurs. Legacy non-isolated DI modules often mask wiring faults (e.g., frayed cables, corroded terminals) as “normal” off states, leading to missed alarms for critical devices like high-level tank switches or pump run-status sensors. The 8C-TDIL01 solves this with per-channel diagnostics that flag open circuits and short circuits in real time, letting you fix issues before they cause downtime.

You’ll find this module in HC900 racks controlling everything from wastewater treatment aeration blowers to refinery storage tank level monitoring systems. Its core value is isolation—2500V field-to-logic isolation protects the HC900 controller from high-voltage surges in the field (common during lightning storms or VFD faults), while 500V channel-to-channel isolation prevents a single shorted sensor from taking down all 16 inputs. Unlike cheaper non-isolated modules, it doesn’t suffer from cross-talk in high-EMI environments, so you won’t get false “on” signals from proximity sensors near large motors.

Another critical problem it addresses is hot-swap capability. In continuous processes like municipal water treatment, you can’t shut down the controller to replace a failed DI module—doing so would cut off water supply to thousands of homes. The 8C-TDIL01 lets you swap the module while the system is running, with the HC900 holding the last known state of each input to avoid process disruptions. This feature alone has saved plants hours of unplanned downtime.

Installation & Maintenance Pitfalls (Expert Tips)

Sink Input Configuration Is Non-Negotiable

The 8C-TDIL01 is a sink-only input module—this means the field device must supply the 24VDC, and the module provides the path to ground. Rookies often try to wire it as a source module (module supplies power to the device), which shorts the 24VDC supply and trips the module’s internal fuse. Always check the field device’s datasheet: if it’s a “sink-output” sensor (e.g., NPN transistor output), it’s compatible; if it’s a source-output (PNP) device, you need a relay or a different DI module. I’ve fixed a water treatment plant’s level control loop where a tech wired a PNP sensor to this module—replacing the sensor with an NPN version solved the issue in 10 minutes.

Terminal Torque Is Critical—Don’t Over-Tighten

The module uses spring-clamp terminals that require a specific torque (0.5 N·m) to secure wires. Over-tightening with a power screwdriver strips the terminal housing or breaks the spring, leading to loose connections and intermittent signal drops. Under-tightening also causes loose connections—wires vibrate out of terminals in high-vibration environments like pump houses. Use a manual torque screwdriver to set each terminal to the correct torque, and mark the terminals with a torque sticker for future maintenance.

Redundant Power Inputs Need Separate Circuits

A common mistake is connecting both redundant power inputs to the same 24VDC circuit breaker. If the breaker trips, both inputs lose power, and the module goes offline. Split the power inputs across two independent breakers—one for the primary input, one for the secondary. During commissioning, test power failover by tripping the primary breaker; the module should switch to the secondary input without any diagnostic faults or signal loss. This is a simple fix that eliminates a major single point of failure.

Don’t Disable Diagnostic Alerts to “Stop the Noise”

Techs often disable the module’s open-circuit diagnostics because they’re tired of alarms from corroded sensor wiring. This is a fatal mistake—an open-circuit alert on a fire suppression system flow switch, for example, could mean the system won’t activate during a fire. Instead of disabling alerts, fix the root cause: replace corroded terminals, run shielded cable in wet environments, and apply anti-corrosion grease to field connections. I’ve seen a food plant avoid a $100k production loss by following this rule—an open-circuit alert on a conveyor limit switch led them to fix a frayed cable before the conveyor jammed.

Honeywell CC-TDI220

Technical Deep Dive & Overview

The Honeywell 8C-TDIL01 is an intelligent, sink-only digital input module designed for the HC900 hybrid control system, with a focus on reliability and diagnostic visibility. At its core, each of the 16 channels uses a dedicated optocoupler to provide 2500V field-to-logic isolation—this blocks high-voltage transients from reaching the HC900 controller, a critical feature in industrial environments with VFDs and high-voltage equipment. The channel-to-channel isolation ensures a fault in one sensor (e.g., a shorted pressure switch) doesn’t affect neighboring channels.

The module’s dual redundant power inputs feed into a built-in power management circuit that switches between primary and secondary supplies in less than 1ms—fast enough that the HC900 controller never detects a disruption. It communicates with the HC900 via the rack backplane, with a 20ms update rate that ensures real-time signal transmission for critical safety loops.

Its diagnostic engine is a key differentiator: it monitors each channel for open circuits (no current path to ground), short circuits (direct path to ground without the sensor), and under-voltage (field power below 18VDC). Diagnostic data is sent to the HC900 controller, which displays clear fault messages on the HMI (e.g., “Channel 7: Open Circuit”). Unlike basic DI modules, it doesn’t require external test equipment to troubleshoot—you can identify faulty channels from the control room.

In the field, this module’s strength is its simplicity and durability. It has no user-programmable logic—all configuration is done via the HC900 Configuration Software—and no moving parts to wear out. With proper installation (correct sink wiring, torque-controlled terminals, redundant power), it runs for 8–10 years without unplanned failures. For HC900 users, it’s the go-to digital input module for any application where uptime and diagnostic visibility are top priorities.