Description

Key Technical Specifications

- Input Performance: It supports multiple common analog signal types, including voltage signals of 0 – 5V, 1 – 5V, 0 – 10V and current signals of 0 – 20mA, 4 – 20mA. The voltage input impedance is ≥1MΩ, and the current input impedance is 250Ω, which can be well-matched with various industrial sensors.

- Accuracy & Resolution: With 16-bit resolution, it can capture tiny changes in analog signals. The full-scale accuracy reaches ±0.05%, ensuring the reliability of data for precision process control.

- Isolation & Protection: It has 1500V AC channel-to-channel isolation, which effectively avoids mutual interference between different input channels and protects the module from voltage surges. It also has inherent anti-interference performance that complies with EN 61000 – 6 – 2 and EN 61000 – 6 – 4 EMC standards.

- Power & Environmental Parameters: The power supply is 24VDC ±20% with a power consumption of 5W. It has strong environmental adaptability, operating at – 40°C to +70°C and storing at – 40°C to +85°C. It can work normally in 5% – 95% non-condensing humidity environments.

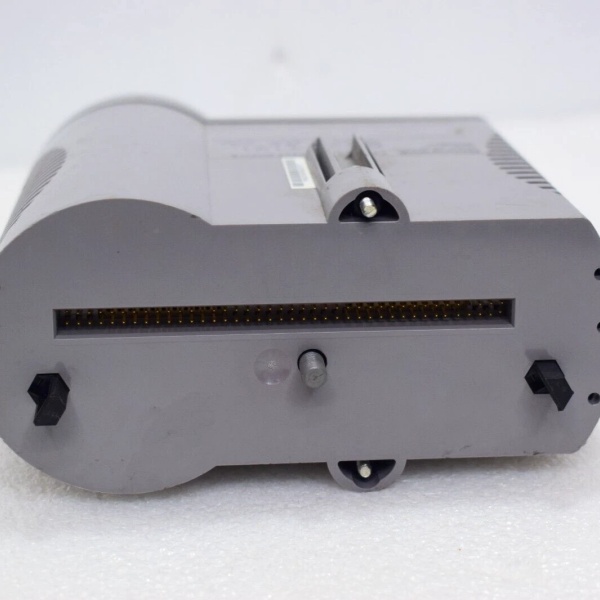

- Physical & Installation: It weighs about 0.4 – 0.5kg, and some sources record different weights due to packaging differences. It adopts DIN rail mounting, with compact dimensions, facilitating installation in control cabinets and saving space. The configurable response time of 5ms – 100ms can meet the needs of different speed process monitoring.

Honeywell CC-PFB801

Field Application & Problem Solved

This module is a core component for data acquisition in industrial control. In oil refineries, it can collect pressure signals of crude oil pipelines and flow signals of distillation towers; in manufacturing workshops, it can acquire temperature signals of production equipment and material level signals of storage tanks. These data are then transmitted to the C200/C300 controller for analysis and decision-making.

It solves two major industrial pain points. On one hand, it solves the problem of incompatible signal types from various sensors through multi-signal compatibility, eliminating the need for additional signal converters and reducing system complexity. On the other hand, its 1500V high isolation design resolves cross-channel interference in high-EMI environments such as power workshops and inverter rooms. For example, it can avoid false signal fluctuations caused by nearby high-power equipment, which ensures the stability of the control system.

Honeywell CC-PFB801

Installation & Maintenance Pitfalls (Expert Tips)

- Confirm Signal Matching Before Wiring: Different sensors output different signal types. For instance, when connecting a 4 – 20mA pressure transmitter, ensure the module channel is configured to the current input mode. Wiring errors between voltage and current signals will either result in no data collection or damage the internal circuit of the module. It is recommended to use a multimeter to verify the sensor output signal before connection.

- Pay Attention to Power Supply Stability: The module relies on a 24VDC power supply with a ±20% fluctuation range. Do not connect it to an unregulated power source. Unstable voltage will cause data drift. It is advisable to use a redundant power supply in safety-critical scenarios to prevent sudden power failure from affecting data acquisition.

- Do Not Ignore Response Time Configuration: The module’s response time can be adjusted between 5ms – 100ms. Do not set a unified parameter for all channels. For fast-changing signals such as flow in chemical reactions, select a short response time of 5 – 20ms. For stable temperature signals, a longer response time can be set to reduce data noise.

- Regularly Calibrate to Maintain Accuracy: Although the module has high precision, long-term operation in harsh environments such as high temperature and vibration will lead to accuracy deviations. It is recommended to perform full-scale calibration once a year using standard signal generators. Ignoring calibration may result in deviations in process control indicators and affect product quality or production safety.