Description

Key Technical Specifications

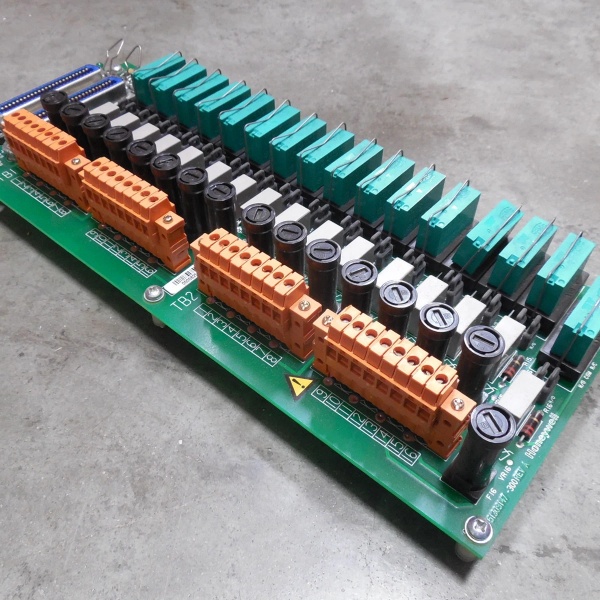

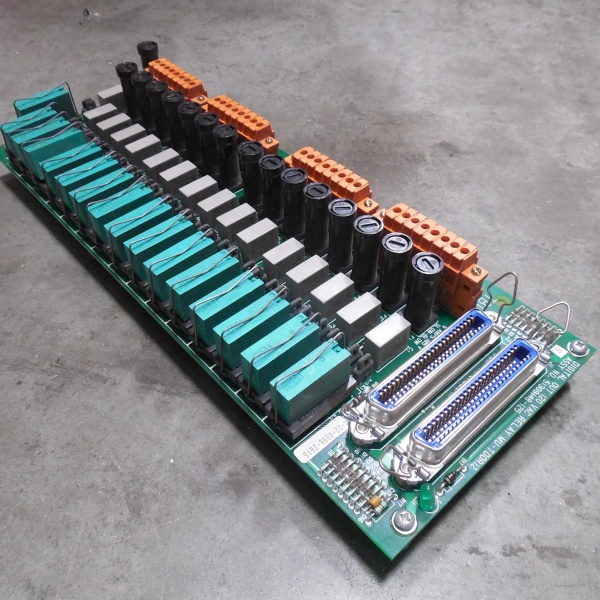

- Output Configuration: Equipped with 16 independent electromechanical relays. The contact type can be switched between Form A (SPST/NO, normally open) and Form B (SPST/NC, normally closed) via jumpers, which is flexible for different control requirements.

- Voltage & Current Capacity: The rated applicable voltage is 120VAC, and it can also be compatible with 125VDC signal control of field equipment. The steady – state load current can reach 5A RMS under 120VAC resistive load, 2A under 30VDC and 0.5A under 125VDC.

- Switching Performance: The typical turn – on and turn – off time is 10ms, and the maximum does not exceed 15ms, which can meet the requirements of most industrial scenarios for real – time switching.

- Protection & Isolation: The channel – to – channel and channel – to – system common end isolation reaches 1500VAC RMS or ±1500VDC, which effectively avoids signal interference. Each contact is equipped with a 22Ω/0.1µF resistor – capacitor snubber circuit for contact suppression, and each output is configured with a 6A 125V slow – blow fuse for overload protection.

- Environmental Adaptability: It follows the environmental standards of the same series. The operating temperature is generally – 25°C to +60°C, and the storage temperature is – 40°C to +70°C, which can adapt to the temperature changes of general industrial workshops and control rooms.

Honeywell 51309148 – 125

Field Application & Problem Solved

Traditional relay modules may have problems such as poor compatibility with Honeywell’s dedicated control systems, unstable contact switching, and lack of effective over – current and interference protection, which may lead to misoperation of executive components and affect the stability of the production process. The 51309148 – 125 module solves these problems well. Its seamless compatibility with Honeywell’s mainstream distributed control systems avoids the trouble of additional adaptation transformation. The built – in fuse and snubber circuit can prevent the module from being damaged due to overload and arc erosion of contacts, ensuring the stable operation of the control loop. For example, in a chemical production line, it can accurately control the switching of feeding valves according to the instructions of the TDC 3000 system, ensuring the accuracy of the feeding process.

Honeywell 51309148 – 125

Installation & Maintenance Notes

- Confirm Contact Configuration: Before installation, select the appropriate contact type (normally open/normally closed) through jumpers according to the control logic of the field equipment. Wrong configuration will directly lead to the failure of the equipment to act as required.

- Pay Attention to Voltage Matching: The module is designed for 120VAC. Do not connect it to an ultra – rated voltage power supply such as 220VAC, otherwise the internal relay will be burned out instantly. It is recommended to test the input voltage with a multimeter before power – on.

- Protect Fuse Replacement: When the module output fails, check whether the 6A 125V slow – blow fuse of the corresponding channel is blown first. When replacing, use fuses of the same specification. Do not replace them with fuses of higher current rating, so as to avoid loss of overload protection function.

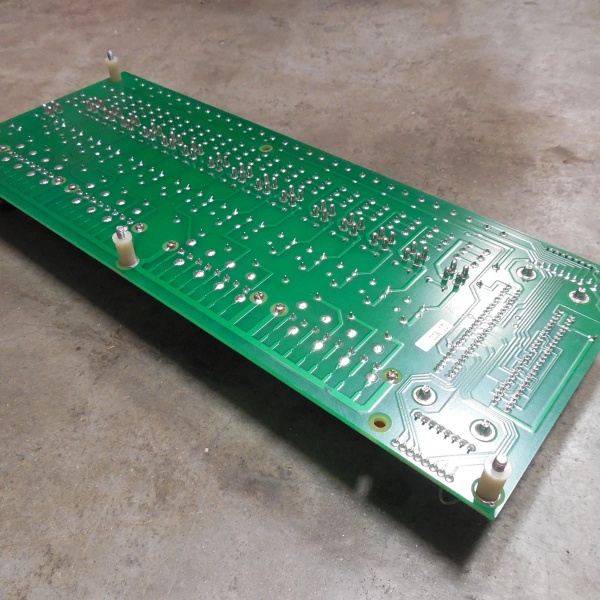

- Handle Used Modules with Caution: A large number of used versions of this module are circulating in the market. When purchasing and using them, check the wear of the terminals and the oxidation of the circuit board. For modules of Rev.B and Rev.C versions, confirm that their firmware matches the system version to prevent communication or control abnormalities.