Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product Model | HIMA F8621A |

| Manufacturer | HIMA |

| Product Category | Communication Module |

| Processor | 32-bit ARM Cortex-A9 |

| Memory | 2 GB RAM, 128 MB Flash |

| Input Voltage | 24V DC ±15% |

| Communication Protocols | Ethernet, RS-485, CANopen, Profibus DP |

| Operating Temperature Range | -40°C to +70°C |

| Storage Temperature Range | -55°C to +85°C |

| Dimensions | 120mm x 80mm x 30mm |

| Weight | 200g |

| Certifications | SIL 3 (IEC 61508), ATEX Ex ia IIC T6 |

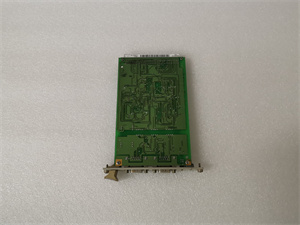

HIMA F8621A

Product Introduction

The HIMA F8621A is a high-performance communication module designed for industrial automation and safety systems. It provides reliable and safe communication between HIMA safety systems and other devices, ensuring seamless integration and enhanced system flexibility.

Core Advantages and Technical Highlights

High Safety Integrity Level

The HIMA F8621A is certified to SIL 3 (IEC 61508) and ATEX Ex ia IIC T6, making it suitable for high-risk applications.

Redundant Communication Architecture

The module features dual-channel redundancy, ensuring continuous operation even in the event of a primary communication link failure.

Robust and Reliable Design

The HIMA F8621A is designed for harsh industrial environments, with a wide operating temperature range and high electromagnetic compatibility (EMC) standards.

Versatile Communication Capabilities

The module supports multiple communication protocols, including Ethernet, RS-485, CANopen, and Profibus DP, facilitating seamless integration with various industrial systems.

HIMA F8621A

Typical Application Scenarios

The HIMA F8621A is widely used in:

-

Oil and Gas: For emergency shutdown systems (ESD) and fire & gas detection systems.

-

Power Generation: For turbine overspeed protection and generator safety interlocks.

-

Chemical Processing: For controlling safety interlocks in reactors and storage tanks.

Related Model Recommendations

-

HIMA F8627: An Ethernet communication module for seamless integration.

-

HIMA F8650X: A CPU module for enhanced system performance.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation

Ensure the environment meets the specified temperature and humidity requirements. Use appropriate tools and safety equipment to secure the module in place. Connect the input and output cables according to the manufacturer’s guidelines.

Maintenance Suggestions

Regularly inspect the module for signs of wear or damage. Keep the unit clean and free from dust to prevent overheating and ensure efficient operation. Perform annual calibration checks and store calibration data in the module’s flash memory.