Description

1. Product Description

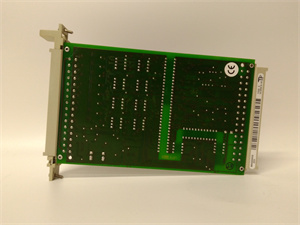

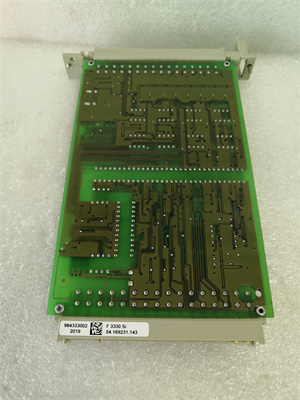

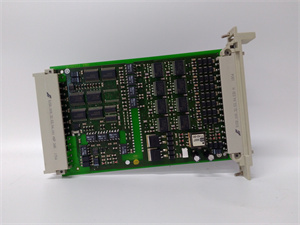

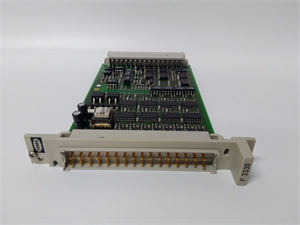

The HIMA F3330 is a top – tier PLC spare part from the highly respected brand HIMA. HIMA has a long – standing track record of producing high – quality automation solutions that are trusted worldwide. The HIMA F3330 is specifically designed to offer precise control and efficient monitoring capabilities in industrial automation setups. Its core function is to manage and regulate industrial processes with a high degree of accuracy, ensuring that operations run smoothly and meet the required standards. This device is widely used in industries such as manufacturing, oil and gas, and food processing. The HIMA F3330 provides several advantages, including high – speed processing, robust reliability, and excellent flexibility, which can significantly enhance the productivity and performance of industrial systems.

2. Product Parameters

| Parameter | Details |

|---|---|

| Voltage | 24V DC (± 15%) |

| Current Consumption | < 1A |

| Communication Interfaces | Ethernet (10/100 Mbps), CANopen, Modbus RTU |

| Number of Inputs/Outputs | Up to 128 configurable I/Os |

| Processing Speed | Instruction execution time < 0.5 ms |

| Operating Temperature | – 25°C to + 60°C |

| Storage Temperature | – 40°C to + 85°C |

| Humidity | 5% – 95% non – condensing |

F3330

3. Advantages and Features

The HIMA F3330 comes with a number of outstanding advantages. Its high – speed processing is a key differentiator. In a manufacturing plant, it can execute complex control programs in a very short time, with an instruction execution time of less than 0.5 ms. This enables real – time response to process changes and improves the overall efficiency of the production line. It also has a high level of reliability. In a long – term field test in an oil and gas facility, the HIMA F3330 operated continuously for over 6 years without any major failures. Moreover, it offers excellent flexibility. The number of inputs and outputs can be easily configured according to the specific needs of different applications, allowing for seamless integration into various industrial systems.

4. Application Areas and Application Cases

The HIMA F3330 is suitable for a wide range of industries and scenarios. It is commonly used in the automotive manufacturing industry for controlling robotic assembly lines, in the food and beverage industry for regulating production processes, and in the oil and gas industry for monitoring pipeline operations.

In an automotive manufacturing plant, the HIMA F3330 was used to control a robotic welding station. Before its installation, the welding process had issues with inconsistent quality and slow cycle times. After implementing the HIMA F3330, the welding quality became more consistent, and the cycle time was reduced by 20% due to its high – speed processing and precise control capabilities.

5. Competitor Comparison

Compared to other products in the market, the HIMA F3330 stands out with its high – speed processing and long – term reliability. Some competing products may offer lower prices, but they often lack the processing power and the proven reliability of the HIMA F3330. In terms of flexibility, the HIMA F3330 also provides a more user – friendly solution, allowing for easy customization and integration.

F3330

6. Selection Suggestions

When selecting the HIMA F3330 or similar PLC spare parts, several factors should be considered. Compatibility is crucial. Ensure that the spare part is compatible with your existing automation system, including controllers, sensors, and actuators. The installation environment is also important. If the environment is harsh, such as having high levels of dust, moisture, or electromagnetic interference, choose a model with appropriate protection levels. Budget is another factor. While the HIMA F3330 offers excellent performance, you need to balance the cost with your specific requirements.

7. Precautions

When using and installing the HIMA F3330, strict safety regulations must be followed. Ensure that the power supply is properly connected and meets the specified voltage requirements. During installation, avoid electrostatic discharge and ensure that all cables are securely connected. Regular maintenance is recommended, including checking for loose connections, cleaning the device, and performing firmware updates to keep it operating at peak performance.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.