Description

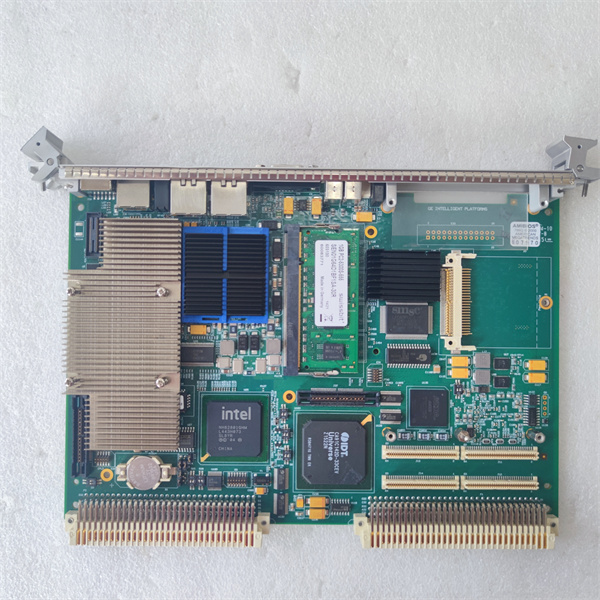

GE V7768 – 312001

Detailed parameter table

| Parameter name | Parameter value |

| Product model | V7768 – 312001 |

| Manufacturer | GE Fanuc Intelligent Platforms |

| Product category | VMEbus single – board computer |

| Processor | Intel Core 2 Duo, capable of reaching up to 2.16 GHz (also available with Intel Celeron M up to 1.07 GHz) |

| Memory | Up to 2 GB of DDR2 SDRAM via a single SODIMM slot. Supports up to 8 GB of bootable CompactFlash |

| I/O options | Dual gigabit ethernet ports for high – speed network connectivity. Two Serial ATA (SATA) interfaces for storage expansion. Four USB 2.0 ports for connecting various peripheral devices. Features a Keyboard/Mouse/SVGA interface on the front panel. Equipped with a PCI – X capable PMC site for further customization and expansion |

| Bus interface | Complies with the VME 6U standard, ensuring compatibility with a wide range of VME – based systems |

| Operating temperature | Available in both commercial and extended temperature ranges, suitable for diverse operating environments |

| Weight | Approximately 2500g |

| Shipping port | Xiamen (common shipping origin) |

GE V7768-312001 350-9301007768-312001-A0

Product introduction

The GE V7768 – 312001 is a high – performance VMEbus single – board computer engineered to meet the stringent demands of industrial, military, aerospace, and other critical applications. As a key component in embedded systems, it offers a powerful combination of processing capabilities, memory resources, and extensive I/O flexibility.

Based on the VME 6U form factor, the V7768 – 312001 seamlessly integrates into existing VME – based systems, providing an upgrade path for legacy systems or a foundation for new, high – performance setups. Its compact design, yet high – density functionality, makes it an attractive option for applications where space is at a premium but performance cannot be compromised.

When powered on, the board undergoes a comprehensive self – test sequence. LEDs on the board indicate the status of various components during this startup process. Once the self – test is successfully completed, the board is ready to execute its assigned tasks, whether it’s data acquisition, control processing, or network communication.

Core advantages and technical highlights

High – performance processing: The Intel Core 2 Duo processor at the heart of the V7768 – 312001 enables rapid execution of complex algorithms and data – intensive tasks. In applications such as real – time data processing in industrial control systems or high – speed signal analysis in military radar systems, the high processing speed ensures that operations are carried out with minimal latency. For example, in a manufacturing plant’s quality control system, the board can quickly analyze sensor data from multiple inspection points to detect defects in products as they move along the production line.

Ample memory configuration: With up to 2 GB of DDR2 SDRAM and support for 8 GB of bootable CompactFlash, the V7768 – 312001 can store large amounts of data and programs. The DDR2 SDRAM provides fast access for real – time data processing, while the CompactFlash offers a reliable and non – volatile storage solution for boot – up files, system configurations, and long – term data storage. This is crucial in applications where continuous operation and data retention are essential, such as in telecommunications network equipment where the board may need to store routing tables and software updates.

Rich I/O capabilities: The dual gigabit ethernet ports facilitate high – speed data transfer, allowing the board to communicate efficiently with other networked devices. In a factory – wide network, it can quickly send and receive data from programmable logic controllers (PLCs), distributed control systems (DCS), and other intelligent devices. The two SATA interfaces enable easy expansion of storage capacity, which is useful in applications that require large – scale data storage, like medical imaging systems where high – resolution images need to be stored. The four USB 2.0 ports provide flexibility for connecting various peripherals, such as keyboards, mice, or external storage devices. The PCI – X capable PMC site further expands the board’s functionality by allowing the addition of custom – designed mezzanine cards.

Robust design for harsh environments: Available in both commercial and extended temperature ranges, the V7768 – 312001 is designed to operate reliably in rugged conditions. In industrial settings with high levels of electromagnetic interference, extreme temperatures, or mechanical vibrations, the board’s robust construction and shielding protect its sensitive components. For instance, in oil and gas drilling platforms, where the equipment is exposed to harsh environmental conditions, the V7768 – 312001 can continue to function properly, ensuring the continuous operation of control and monitoring systems.

Software compatibility: The board offers compatibility with a wide range of operating systems, including Linux, Windows, and real – time operating systems (RTOS). This allows developers to choose the most suitable operating system for their specific application requirements. In industrial automation, an RTOS may be preferred for its deterministic behavior and ability to handle time – critical tasks, while in a more general – purpose data – processing application, Windows or Linux might be more appropriate. The compatibility also extends to software development tools, making it easier for developers to write, test, and deploy applications on the V7768 – 312001.

Typical application scenarios

Industrial automation: In manufacturing plants, the V7768 – 312001 can be used as the control center for complex production lines. It can manage the operation of robotic arms, conveyor belts, and other automated machinery. For example, in an automotive assembly plant, the board receives input signals from sensors that detect the position of car parts, the status of assembly robots, and the quality of welds. Based on this data, it sends out control signals to ensure the smooth and accurate execution of the assembly process. It can also communicate with the plant’s management system to provide real – time production data, such as production rates, equipment utilization, and defect rates, enabling better production planning and quality control.

Telecommunications: In the telecommunications industry, the V7768 – 312001 can be used in network equipment such as routers and switches. It can handle the high – speed data routing and switching operations required in modern telecommunications networks. For example, in a large – scale data center network, the board can process and forward packets at gigabit speeds, ensuring seamless communication between servers, storage devices, and end – user devices. It can also be used in network monitoring systems, where it analyzes network traffic patterns to detect and prevent network congestion, security threats, and service disruptions.

Military and aerospace: In military and aerospace applications, the V7768 – 312001’s high – performance processing, rugged design, and software compatibility make it an ideal choice. In military aircraft, it can be used for avionics systems, such as flight control, navigation, and communication systems. It can process sensor data from various aircraft sensors, such as radar, GPS, and inertial measurement units, in real – time to ensure the safe and efficient operation of the aircraft. In aerospace ground support equipment, the board can be used for data acquisition and control tasks, such as monitoring and controlling the fueling process, aircraft maintenance equipment, and test stands.

Medical imaging: In the field of medical imaging, the V7768 – 312001 can enhance the performance of medical equipment such as CT scanners, MRI machines, and ultrasound devices. It can process and analyze the large amounts of data generated by these imaging systems in real – time to produce high – quality images. For example, in a CT scanner, the board can quickly reconstruct the raw data from the X – ray detectors into detailed 3D images of the patient’s internal organs, enabling doctors to make more accurate diagnoses. The board’s ability to support high – resolution displays and storage expansion also makes it suitable for medical imaging applications where large – scale data storage and visualization are required.

GE V7768-312001 350-9301007768-312001-A0

Related model recommendations

GE V7768 – 320001: This model is also a VMEbus single – board computer from GE Fanuc. It shares many similarities with the V7768 – 312001, such as the use of the Intel Core 2 Duo or Celeron M processors, VME 6U bus interface, and rich I/O capabilities. However, it may have some differences in specific features or configurations. For example, it might offer different memory upgrade options or additional I/O interfaces. In applications where the base functionality of the V7768 – 312001 is suitable but a slightly different feature set is required, the V7768 – 320001 could be a viable alternative.

GE Series 90 – 70 I/O modules: These I/O modules are highly compatible with the V7768 – 312001. The discrete I/O modules can be used to interface with sensors and actuators that provide or require digital on – off signals. In an industrial automation application, a Series 90 – 70 discrete input module can be used to connect limit switches, proximity sensors, and pushbuttons to the V7768 – 312001, while a discrete output module can be used to control relays, solenoids, and motor starters. The analog I/O modules in the Series 90 – 70 range are useful for connecting to sensors and actuators that deal with continuous signals, such as temperature sensors, pressure transducers, and variable – speed drives. By combining the V7768 – 312001 with these I/O modules, a comprehensive and flexible control system can be built.

GE HMI devices: Human – Machine Interface (HMI) devices are essential for operators to interact with the control system. GE offers a range of HMI devices that work well with the V7768 – 312001. These HMI devices can display real – time process data, such as the status of machines, the values of process variables, and any alarms or warnings. Operators can also use the HMI to input commands, change setpoints, and configure the control system. For example, a GE touch – screen HMI can be used to provide an intuitive interface for operators in an industrial plant to monitor and control the production process. The seamless integration between the V7768 – 312001 and GE HMI devices enhances the overall usability and efficiency of the control system.

Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that all power sources in the target system are turned off. This includes the main power supply and any local power sources for associated devices. Thoroughly inspect the VME 6U backplane where the V7768 – 312001 will be installed for any signs of damage, such as bent pins or corroded contacts. Clean the backplane slots using a suitable cleaning agent to ensure a proper electrical connection. Verify that the power supply available for the board is within the specified voltage and current ratings. Use anti – static wrist straps or other anti – static measures when handling the board to prevent electrostatic discharge, which could damage the sensitive electronic components. Prepare the necessary cables for the I/O interfaces, such as ethernet cables, SATA cables, and USB cables, ensuring that they are of the correct type and properly shielded. Familiarize yourself with the installation diagrams provided in the user manual, which clearly show the pin – out details for the various ports and the correct orientation of the board in the backplane.

Commissioning steps: Carefully mount the V7768 – 312001 in the appropriate slot on the VME 6U backplane using the provided mounting hardware and secure it firmly. Connect the power supply wires to the board according to the wiring diagram in the user manual. Connect the cables for the I/O interfaces to their respective devices, such as network switches for ethernet, storage devices for SATA, and peripherals for USB. Power on the system and observe the LED lights on the board. The power LED should be illuminated steadily, indicating that the board is receiving power. The ethernet status LEDs should show the correct link and activity status if the network connections are properly configured. Use the appropriate software development tools or operating system installation media to configure the board. Set up parameters such as the network settings for the ethernet ports, the storage configuration for the SATA interfaces, and the device drivers for the peripherals. Test the functionality of the board by running diagnostic tests or simple applications. For example, you can use network testing tools to verify the network connectivity or storage benchmarking tools to test the performance of the SATA interfaces.

Maintenance suggestions: Regularly perform visual inspections of the V7768 – 312001. Check for any loose connections, signs of overheating (such as discolored components or a burning smell), or physical damage to the board’s enclosure. Clean the board periodically to remove dust and debris, as these can accumulate and cause electrical interference or overheating, especially in industrial environments with high levels of particulate matter. Use a soft brush or compressed air to clean the board. Monitor the board’s performance through the operating system’s built – in monitoring tools or dedicated software. Look for any abnormal behavior, such as high CPU utilization, network errors, or storage failures. If a problem is detected, first check the wiring connections to ensure they are secure. If the issue persists, use the diagnostic tools provided by the manufacturer or the operating system to perform detailed self – diagnostic tests on the board. In case of a component failure, replace the faulty component with a genuine replacement part. For example, if the DDR2 SDRAM module fails, obtain a compatible GE – branded SDRAM module and follow the step – by – step instructions in the user manual to replace it without causing any damage to other components on the board. Also, keep the software and drivers up – to – date to ensure optimal performance and compatibility with the latest hardware and software technologies.

Service and guarantee commitment

GE Fanuc Intelligent Platforms offers a comprehensive service and guarantee package for the V7768 – 312001. They provide a standard warranty period, which typically covers manufacturing defects and performance issues under normal operating conditions. Their global technical support team is available to offer assistance. In case of problems, they can perform remote diagnostics and troubleshooting via secure connections. If the issue cannot be resolved remotely, GE can dispatch on – site technicians to the location.

Customers have access to a wealth of online resources, including detailed user manuals, technical specifications, and software development tools for the V7768 – 312001. Training courses are also available, either online or in – person, to help users understand the board’s installation, configuration, and maintenance. These training programs are designed to enhance the user’s skills and knowledge, enabling them to make the most of the board’s capabilities. Extended warranty options may be available, which can provide additional coverage and services such as preventive maintenance checks. This commitment to support ensures that customers can rely on the V7768 – 312001 for reliable and efficient operation in their applications.