Description

Detailed Parameter Table

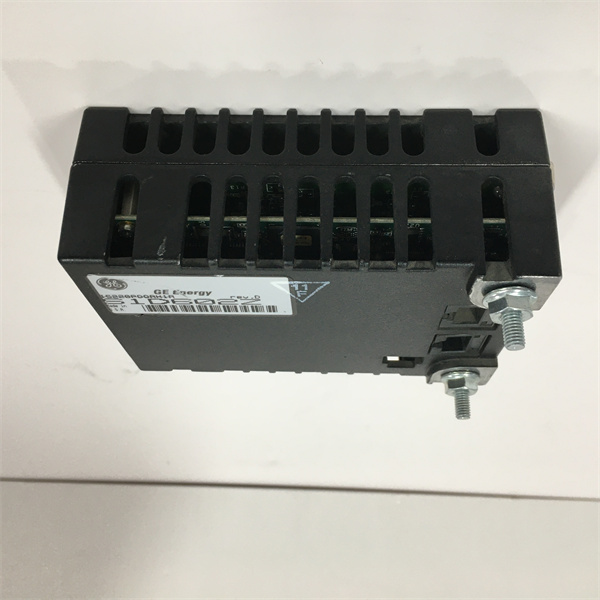

**

| Parameter name | Parameter value |

| Product model | IS220PDOAH1A |

| Manufacturer | GE (General Electric) |

| Product category | Discrete Output Pack |

| Compatible with | Six discrete output terminal boards, including SRly and TRly |

| Connectors | 1 DC connector, 2 RJ45 connectors |

| Dimensions | 3.25″ high x 1.65″ wide x 4.78″ deep |

| Memory types | Flash and RAM |

| Number of Ethernet ports | Two |

| Number of LEDs | Four (Power, Attention, TxRx, Link) |

| Power management | 28 V input |

| Relay channels quantity | 12 |

| Technology | Surface – mount |

| Operating temperature range | – 40 °C to + 70 °C |

| Storage temperature range | – 55 °C to + 85 °C |

| Relative humidity | 5% – 95% non – condensing |

| Weight | 640g |

| Warranty | 12 months |

GE IS220PDOAH1A

Product Introduction

The GE IS220PDOAH1A is a discrete output pack that plays a crucial role in industrial control systems, especially within the General Electric Speedtronic Mark VIe gas turbine control system. Engineered with precision, this module is designed to efficiently convert electrical signals into control signals for actuating various real – world equipment. It serves as a reliable interface between the control system and the actual devices, ensuring seamless operation and accurate control in industrial settings.

Core Advantages and Technical Highlights

High – capacity relay control: With the ability to control up to 12 relays, the IS220PDOAH1A offers significant flexibility in device actuation. These relays can be used to control a wide range of equipment such as valves, motors, and indicator lights. For example, in an industrial process plant, it can control the opening and closing of valves to regulate the flow of fluids or start and stop motors that drive conveyor belts. The large number of relay channels allows for the integration of multiple devices into a single control loop, simplifying the overall system design.

Versatile relay compatibility: The module is compatible with both solid – state relays (used with TRlyH1B, C, D, and F terminals) and electromagnetic relays (used with TRlyH1E boards). This versatility enables it to be used in different types of applications, depending on the specific requirements of the equipment being controlled. Solid – state relays are often preferred for applications that require fast switching speeds and long – term reliability, while electromagnetic relays may be more suitable for applications that need to handle higher currents.

Efficient electrical interface and communication: The IS220PDOAH1A provides one or two I/O Ethernet networks connected to a discrete output terminal board. This allows for seamless communication and data exchange between the control system and other devices or subsystems. The two RJ45 Ethernet connectors enable high – speed data transfer, ensuring that control signals are transmitted accurately and in a timely manner. In a power station control system, for instance, the module can quickly communicate control commands to various actuators based on the data received from sensors and controllers, enhancing the overall efficiency of the power generation process.

Powerful monitoring and diagnostic capabilities: The module is equipped with four LEDs (Power, Attention, TxRx, Link) that provide visual diagnosis, allowing users to quickly assess the working status of the module. Additionally, it has an infrared port for local diagnostic serial communication. This feature is extremely useful for maintenance and troubleshooting purposes. In case of a system malfunction, technicians can use the infrared port to access detailed diagnostic information, identify the root cause of the problem, and take appropriate corrective actions, minimizing downtime and maintenance costs.

Typical Application Scenarios

Gas turbine control systems: In gas turbine power plants, the IS220PDOAH1A is used to control various components such as fuel valves, inlet guide vanes, and generator exciters. It receives control signals from the turbine control system and converts them into electrical signals to actuate the relays, which in turn control the operation of these components. For example, it can adjust the fuel valves to control the amount of fuel injected into the combustion chamber, ensuring optimal combustion efficiency and power output.

Industrial automation in manufacturing plants: In manufacturing facilities, the module can be used to control the operation of production equipment. It can control the start and stop of motors that drive machinery, activate pneumatic or hydraulic valves to control the movement of robotic arms, and turn on or off indicator lights to signal the status of different production processes. In an automotive assembly line, for instance, the IS220PDOAH1A can be used to control the operation of conveyor belts, robotic welders, and painting equipment, ensuring smooth and efficient production.

Power distribution and monitoring systems: In power distribution networks, the module can be used to control circuit breakers, switches, and other power – related devices. It can receive signals from sensors that monitor voltage, current, and other electrical parameters and use these signals to actuate the relays and control the operation of the power distribution equipment. This helps in ensuring the stable and reliable operation of the power grid, protecting against over – current and other electrical faults.

GE IS220PDOAH1A

Related Model Recommendations

GE IS220PAICH1A: The IS220PAICH1A is an advanced analog I/O pack. In some industrial control applications, the IS220PDOAH1A can be used in combination with the IS220PAICH1A. While the IS220PDOAH1A focuses on discrete output functions, the IS220PAICH1A can handle analog input and output signals. For example, in a complex industrial process control system, the IS220PAICH1A can be used to acquire analog data from sensors such as temperature and pressure sensors, and the IS220PDOAH1A can be used to control discrete devices based on the processed data.

GE VMIVME – 1150: The VMIVME – 1150 is a 64 – bit optically coupled digital input board. In certain industrial setups, the IS220PDOAH1A can work in tandem with the VMIVME – 1150. The VMIVME – 1150 can receive digital input signals from sensors, and the IS220PDOAH1A can be used to provide control signals to actuators based on these input signals. For instance, in an industrial automation system, the VMIVME – 1150 can detect the status of limit switches, and the IS220PDOAH1A can control the operation of motors or valves accordingly.

GE D20ME – VME: This VME module can serve as a central processing or communication hub in a system where the IS220PDOAH1A is used for discrete output functions. The D20ME – VME offers features such as multiple communication interfaces (RS – 232, RS – 485, Ethernet) and overcurrent protection. It can communicate with the IS220PDOAH1A, enabling seamless integration of discrete output control with other data acquisition, control, and communication functions in the system.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS220PDOAH1A, ensure that the power to the control system is turned off. Use anti – static precautions to prevent electrostatic discharge (ESD) damage to the module. Check that the physical dimensions of the installation location are compatible with the module’s dimensions. Verify that the power supply in the system can provide the required 28 V input. Ensure that the Ethernet network infrastructure is properly configured to connect to the module’s RJ45 connectors.

Commissioning: Once installed, power on the system. Use the appropriate software or control interface to configure the module’s settings, such as the relay control parameters and communication settings. Test each relay channel by sending control signals and verifying that the connected devices respond correctly. Check the status of the LEDs to ensure that the module is operating normally. Monitor the communication between the module and other devices in the system to ensure seamless data transfer.

Maintenance suggestions: Regularly perform visual inspections of the IS220PDOAH1A for any signs of physical damage, such as bent pins or discolored components. Check for loose connections on the connectors. Monitor the operating temperature of the module, especially in high – temperature environments, to ensure it remains within the specified range. If any relay channels fail to operate correctly, use diagnostic tools to check for electrical faults, such as short – circuits or open – circuits. Replace the module if any irreparable damage is detected. Given its 12 – month warranty, contact GE’s customer service for any warranty – related issues.

Service and Guarantee Commitment

GE provides a 12 – month warranty for the IS220PDOAH1A, covering manufacturing defects and component failures under normal operating conditions. Technical support is available through GE’s customer service channels, where trained technicians can assist with installation, troubleshooting, and any other technical issues related to the module. Customers can access product documentation, including installation manuals and technical specifications, through GE’s official website. In the event of a warranty claim, GE will work to provide a prompt resolution, either through repair or replacement of the faulty module, to minimize downtime for the customer’s operations.