Description

GE IS220PAICH1A

Detailed parameter table

| Parameter name | Parameter value |

| Product model | IS220PAICH1A |

| Manufacturer | GE (General Electric) |

| Product category | Analog input module for Mark VIe control systems |

| Input type | 8 channels of differential analog inputs |

| Input signal range | 4 – 20 mA, 0 – 10 VDC |

| Resolution | 16 – bit |

| Accuracy | ±0.1% of full scale |

| Isolation | Channel – to – channel and channel – to – ground isolation (2500 VAC) |

| Sampling rate | 100 samples per second per channel |

| Operating temperature | 0°C – 60°C |

| Storage temperature | -40°C – 85°C |

| Humidity tolerance | 5% – 95% RH, non – condensing |

| Power supply | 24 VDC ±10%, 0.5 A maximum |

| Communication interface | Backplane communication with Mark VIe controller |

| Physical dimensions | 120 mm (Length) x 80 mm (Width) x 30 mm (Height) |

| Mounting type | Backplane slot mounting in Mark VIe chassis |

| Weight | 150 g |

| Certification | UL 508, IEC 61010, CE marked |

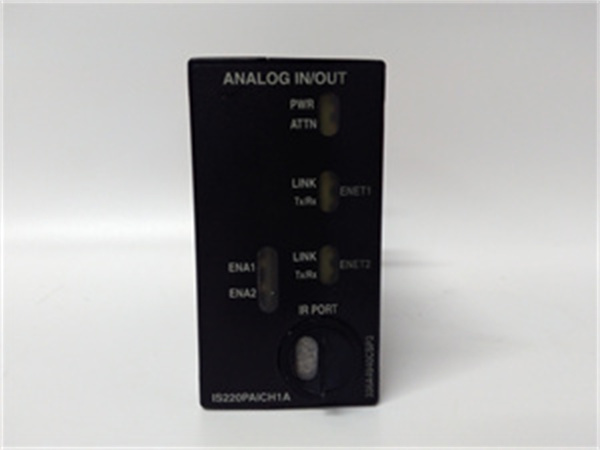

GE IS220PAICH1A

Product introduction

The GE IS220PAICH1A is a high-performance analog input module specifically designed for GE’s Mark VIe control systems, which are widely used in industrial automation, particularly in power generation and turbomachinery control. As a key component in the control system, this module is responsible for converting analog signals from various field sensors into digital data that the controller can process.

In industrial processes, numerous critical parameters such as temperature, pressure, flow rate, and level are measured using analog sensors. The IS220PAICH1A acts as a bridge between these sensors and the control system, accurately capturing the analog signals and transmitting them to the controller. This enables the control system to monitor the process in real-time and make precise adjustments to ensure optimal operation. Whether in a gas turbine power plant, a steam turbine facility, or a large-scale industrial manufacturing plant, the IS220PAICH1A plays an essential role in ensuring the reliability and accuracy of data acquisition, which is fundamental to efficient and safe process control.

Core advantages and technical highlights

High accuracy and resolution: With a 16-bit resolution and an accuracy of ±0.1% of full scale, the IS220PAICH1A can capture even the smallest changes in analog signals. This high level of precision is crucial in applications where minute variations in parameters can have a significant impact on process performance. For example, in a gas turbine, accurately measuring the exhaust gas temperature with this module allows the control system to make precise adjustments to the fuel supply, optimizing turbine efficiency and reducing emissions.

Excellent isolation performance: The module features channel-to-channel and channel-to-ground isolation of 2500 VAC. This isolation prevents electrical noise and interference from one channel from affecting others, ensuring the integrity of the measured data. In industrial environments with high levels of electrical noise, such as near large motors or power distribution systems, this isolation is vital for maintaining accurate measurements. It also enhances the safety of the control system by protecting sensitive electronics from voltage spikes and ground loops.

High sampling rate: With a sampling rate of 100 samples per second per channel, the IS220PAICH1A can quickly capture dynamic changes in the measured parameters. This rapid sampling is essential for real-time control applications where timely data is necessary to respond to process variations. For instance, in a chemical processing plant, monitoring the flow rate of a reactant with a high sampling rate allows the control system to adjust the flow immediately if there is a deviation, preventing process upsets and ensuring product quality.

Versatile input range: The module supports both 4 – 20 mA current signals and 0 – 10 VDC voltage signals, making it compatible with a wide range of analog sensors commonly used in industrial applications. This versatility eliminates the need for additional signal conditioning equipment, simplifying the system design and reducing installation costs. Whether connecting to a pressure transmitter that outputs a 4 – 20 mA signal or a temperature sensor that provides a 0 – 10 VDC signal, the IS220PAICH1A can handle it seamlessly.

Robust design for industrial environments: Built to withstand harsh industrial conditions, the IS220PAICH1A operates reliably in temperatures ranging from 0°C to 60°C and can tolerate high humidity levels. Its rugged construction ensures that it can function properly even in dusty, vibration-prone environments, such as manufacturing plants or power generation facilities. This durability minimizes downtime and maintenance costs, ensuring continuous and reliable operation of the control system.

Typical application scenarios

Gas turbine power plants: In gas turbine power plants, the IS220PAICH1A is used to monitor various critical parameters. It measures the exhaust gas temperature from thermocouples, the compressor discharge pressure from pressure transmitters, and the fuel flow rate from flow meters. These measurements are transmitted to the Mark VIe controller, which uses the data to adjust the fuel supply, guide vane position, and other control variables to optimize turbine performance, ensure safe operation, and reduce emissions.

Steam turbine facilities: In steam turbine facilities, the module plays a key role in monitoring steam pressure, temperature, and flow rate. By accurately measuring these parameters, the control system can adjust the steam inlet valves to maintain the desired turbine speed and power output. For example, if the steam pressure drops, the controller can open the valves to increase steam flow, ensuring that the turbine continues to operate at the required power level. The IS220PAICH1A’s high accuracy ensures that these adjustments are precise, preventing overshooting or undershooting of the setpoints.

Chemical processing plants: In chemical processing, the module is used to monitor parameters such as reactant flow rates, tank levels, and pH values. For instance, in a batch reactor, the IS220PAICH1A measures the flow rate of raw materials entering the reactor, allowing the control system to maintain the correct stoichiometry. It also monitors the temperature inside the reactor, enabling precise control of the heating or cooling system to ensure the reaction proceeds at the optimal rate. The high sampling rate of the module ensures that any changes in these parameters are detected quickly, allowing for immediate corrective actions.

GE IS220PAICH1A

Related model recommendations

GE IS220PAICH2A: This model offers 16 channels of differential analog inputs, making it suitable for applications that require monitoring a larger number of analog parameters. It has the same high accuracy and isolation performance as the IS220PAICH1A, providing a scalable solution for larger control systems.

GE IS220PDOCH1A: A digital output module that can be paired with the IS220PAICH1A. While the IS220PAICH1A acquires analog data, the IS220PDOCH1A sends digital control signals to actuators such as valves and motors, completing the control loop.

GE IS215UCCCM04A: The main processor module of the Mark VIe control system, which processes the digital data received from the IS220PAICH1A and executes control algorithms to adjust the process variables.

GE IS220PTURH1A: A turbine trip pack module that works with the IS220PAICH1A in turbine control systems. The IS220PAICH1A provides critical parameter measurements to the IS220PTURH1A, which uses this data to initiate emergency shutdowns if unsafe conditions are detected.

GE IS200EPMCH1: A power supply module that provides the 24 VDC power required by the IS220PAICH1A, ensuring stable and reliable operation of the analog input module.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the IS220PAICH1A, ensure that the Mark VIe chassis is powered off. Inspect the backplane slot for any dust, debris, or damage, and clean it if necessary. Use anti-static gloves when handling the module to prevent electrostatic discharge from damaging sensitive components. Verify that the 24 VDC power supply is within the range of 24 VDC ±10% and that the wiring to the sensors is correct and properly insulated.

Commissioning steps: Insert the IS220PAICH1A into the designated backplane slot and secure it in place. Power on the Mark VIe chassis and check that the module’s status LED illuminates green, indicating that it is functioning correctly. Use GE’s ToolboxST software to configure the module, setting the input signal type (4 – 20 mA or 0 – 10 VDC) for each channel according to the connected sensors. Calibrate the module using a standard signal generator to ensure accurate measurements. Test each channel by applying a known signal and verifying that the measured value displayed in the control system matches the expected value.

Maintenance suggestions: Perform regular visual inspections of the IS220PAICH1A to check for loose connections, damage to the casing, or signs of overheating. Clean the module’s surface and the backplane slot periodically to remove dust and debris, which can cause electrical interference or overheating. Monitor the module’s performance through the control system, checking for any drift in measurements or communication errors. If a channel is found to be inaccurate, re – calibrate it using the ToolboxST software. Replace the module if it fails to function properly after calibration or if there is physical damage. Always use genuine GE replacement modules to ensure compatibility and performance.

Service and guarantee commitment

GE provides a 2 – year warranty for the IS220PAICH1A, covering manufacturing defects and performance issues under normal operating conditions. Their global technical support team is available 24/7 to assist with any problems, offering remote diagnostics and troubleshooting via secure connections. For complex issues, GE can dispatch on – site technicians to resolve the problem.

Customers have access to GE’s comprehensive online resources, including user manuals, technical specifications, and calibration procedures for the IS220PAICH1A. Training courses are also available to help users understand the module’s installation, configuration, and maintenance. Extended warranty options may be available, providing additional coverage and services such as preventive maintenance checks to ensure the module continues to operate at peak performance. This commitment to support ensures that customers can rely on the IS220PAICH1A for accurate and reliable data acquisition in their industrial control systems.