Description

Key Technical Specifications

-

Model Number: IS215WETAH1BA

-

Manufacturer: General Electric (Salem, VA)

-

Power Supply: 24 VDC ±10 %, 0.8 A typical, 1.3 A max

-

Analog Inputs: 12 differential, 16-bit, ±10 V or 4-20 mA (jumper-select)

-

Discrete Inputs: 16 channels, 24 VDC, 2 ms debounce

-

Relay Outputs: 8 Form-C, 250 VAC / 30 VDC, 2 A resistive

-

Communication: Ionet (100 Mb/s), UDH Modbus-TCP, RS-485 service port

-

Processor: 32-bit ColdFire, 150 MHz, 4 MB battery-backed SRAM

-

Isolation: 500 V channel-to-bus, 1500 V field-to-logic

-

Operating Temperature: –40 °C to +70 °C (conformal-coated)

-

Dimensions: 24.8 × 17.5 × 4.5 cm, 0.5 kg

-

Firmware: Flash-based, upgradeable via ControlST v9.0+

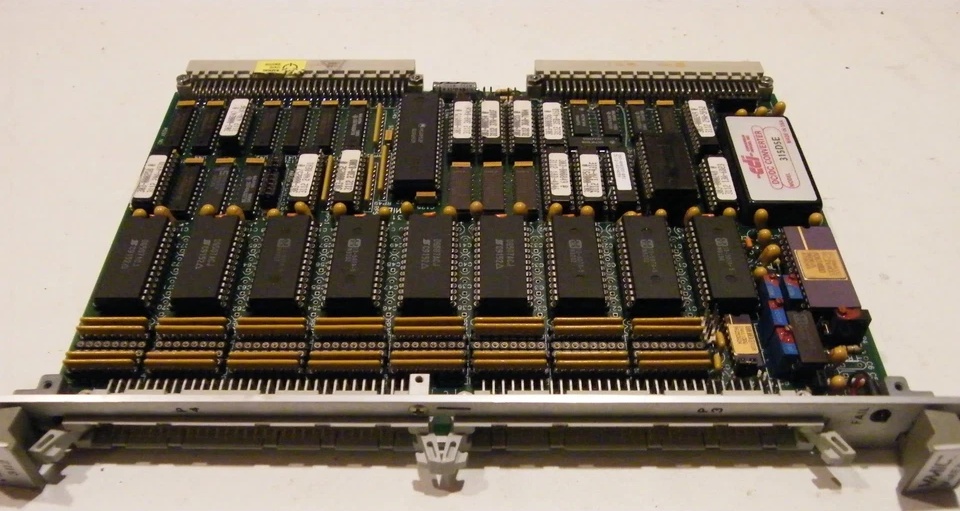

DS2000CPCAG1A

Field Application & Problem Solved

On a 2 MW nacelle you can’t afford gearbox shock when the wind jumps from 8 m/s to 18 m/s in three seconds. The IS215WETAH1BA sits in the top-box, reads the encoder on the high-speed shaft, and trims generator torque 200 times a second so the drivetrain sees a smooth ramp instead of a hammer blow. When the card fails you lose torque control, the turbine defaults to “run-away” brake, and you’re down until the next weather window—swap the board and you’re back to rated power without re-downloading a single parameter. You’ll find this PCB in every GE 1.5–3 MW class from Iowa cornfields to North-Sea jack-ups. Its core value is mechanical sympathy: the torque loop keeps gearbox torque variance under ±2 %, doubling bearing life and keeping the insurance company happy.

On a 2 MW nacelle you can’t afford gearbox shock when the wind jumps from 8 m/s to 18 m/s in three seconds. The IS215WETAH1BA sits in the top-box, reads the encoder on the high-speed shaft, and trims generator torque 200 times a second so the drivetrain sees a smooth ramp instead of a hammer blow. When the card fails you lose torque control, the turbine defaults to “run-away” brake, and you’re down until the next weather window—swap the board and you’re back to rated power without re-downloading a single parameter. You’ll find this PCB in every GE 1.5–3 MW class from Iowa cornfields to North-Sea jack-ups. Its core value is mechanical sympathy: the torque loop keeps gearbox torque variance under ±2 %, doubling bearing life and keeping the insurance company happy.

Installation & Maintenance Pitfalls (Expert Tips)

Conformal coat cracked—salt fog kills the encoder input

The board is coated, but the encoder header is potted after coating. If the potting shrinks, salt bridges the differential pairs and you get intermittent speed drop-outs. Peel the old potting, hit the header with 2100-FTG, and re-pot—problem gone for another decade.

The board is coated, but the encoder header is potted after coating. If the potting shrinks, salt bridges the differential pairs and you get intermittent speed drop-outs. Peel the old potting, hit the header with 2100-FTG, and re-pot—problem gone for another decade.

Battery dead—SRAM loses torque table, turbine hunts

A 3 V lithium cell backs the SRAM. When it drops below 2.2 V the torque curve corrupts and the turbine hunts ±5 kN·m. Cell is solder-tab; cut it out, add a CR2032 holder on the faceplate, and reload the curve via ControlST—five-minute fix, no crane needed.

A 3 V lithium cell backs the SRAM. When it drops below 2.2 V the torque curve corrupts and the turbine hunts ±5 kN·m. Cell is solder-tab; cut it out, add a CR2032 holder on the faceplate, and reload the curve via ControlST—five-minute fix, no crane needed.

Missing shield ground—Ionet drops out in storms

Ionet is 100 Mb copper. If the shield drains at both ends you create a ground loop; drain at the top-box only. Use a shield-through connector and the link stays up even when the tower takes a 50 kA strike.

Ionet is 100 Mb copper. If the shield drains at both ends you create a ground loop; drain at the top-box only. Use a shield-through connector and the link stays up even when the tower takes a 50 kA strike.

Wrong revision—H1B needs different BIOS

H1A and H1B share the same slot but H1B boots from internal flash; drop an H1A image on it and the board faults on “BIOS MISMATCH.” Always burn the correct *.BIN file before you ride the lift—tower time costs more than the card.

H1A and H1B share the same slot but H1B boots from internal flash; drop an H1A image on it and the board faults on “BIOS MISMATCH.” Always burn the correct *.BIN file before you ride the lift—tower time costs more than the card.

Technical Deep Dive & Overview

IS215WETAH1BA is a torque-regulating node on the Ionet ring. A ColdFire MCU reads shaft speed, generator current, and blade-pitch angle, then calculates instantaneous torque demand using a PI loop tuned for wind-speed feed-forward. Results are sent to the converter via Ionet; status and limits are echoed back to the Mark VIe main CPU. The 8 relays give hard-wired overspeed, over-torque, and grid-loss trips that bypass the network—if the FPGA sees 120 % rated torque it drops the relay in 2 ms, crow-barring the converter and saving the gearbox. Treat the encoder cable like a piece of precision instrumentation and the board will keep the drivetrain alive for another thirty years

IS215WETAH1BA is a torque-regulating node on the Ionet ring. A ColdFire MCU reads shaft speed, generator current, and blade-pitch angle, then calculates instantaneous torque demand using a PI loop tuned for wind-speed feed-forward. Results are sent to the converter via Ionet; status and limits are echoed back to the Mark VIe main CPU. The 8 relays give hard-wired overspeed, over-torque, and grid-loss trips that bypass the network—if the FPGA sees 120 % rated torque it drops the relay in 2 ms, crow-barring the converter and saving the gearbox. Treat the encoder cable like a piece of precision instrumentation and the board will keep the drivetrain alive for another thirty years

.