Description

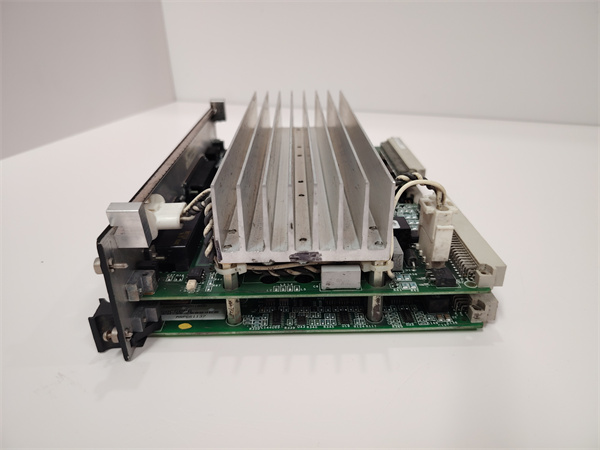

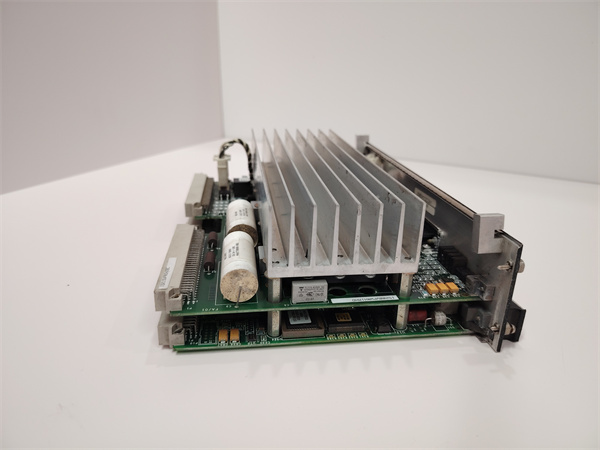

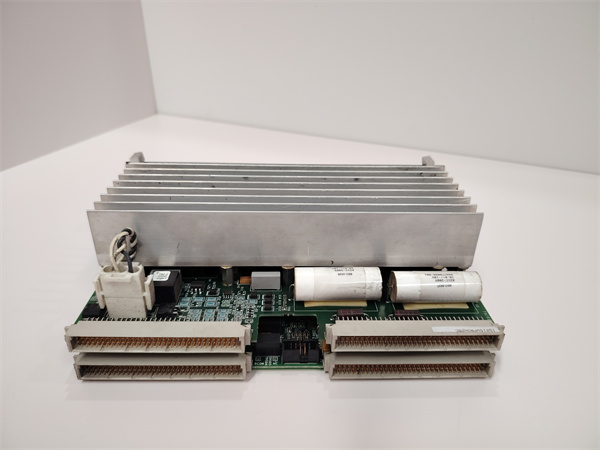

GE IS215VPROH2BC

Detailed parameter table

| Parameter name | Parameter value |

| Product model | IS215VPROH2BC |

| Manufacturer | GE (General Electric) |

| Product category | VMEbus processor module for Mark VIe control systems |

| Processor | 1.8 GHz PowerPC industrial processor |

| Memory | 4 GB DDR3 SDRAM, 16 GB solid-state drive (SSD) |

| Operating system | VxWorks real-time operating system |

| Communication interfaces | 2 x 10/100/1000 Mbps Ethernet (with redundancy), 1 x RS-232 |

| Expansion slots | 1 x PMC (PCI Mezzanine Card) slot for I/O expansion |

| Operating temperature | 0°C to +60°C |

| Storage temperature | -40°C to +85°C |

| Humidity tolerance | 5% – 95% RH, non-condensing |

| Vibration resistance | 10 g peak (11 ms duration) |

| Shock resistance | 50 g peak (11 ms duration) |

| Power consumption | 25 W typical at 5 VDC |

| Physical dimensions | 233 mm x 160 mm (VMEbus form factor) |

| Mounting type | VMEbus backplane mounting |

| Certification | UL 61010, IEC 61010, CE marked |

GE IS215VPROH2BC

Product introduction

The GE IS215VPROH2BC is a high-performance VMEbus processor module designed for GE’s Mark VIe control systems, a leading platform in industrial automation and turbomachinery control. As a core computing component, it serves as the main processing unit for executing complex control algorithms, managing real-time data acquisition, and coordinating communication across the control system.

This module integrates a powerful 1.8 GHz PowerPC processor with robust memory capabilities, enabling it to handle the demanding computational needs of large-scale industrial processes—from turbine speed regulation in power plants to synchronized control of multi-machine production lines. Its VMEbus architecture ensures compatibility with other Mark VIe components, such as I/O modules and communication interfaces, creating a scalable control solution. Whether deployed in power generation, oil and gas, or heavy manufacturing, the IS215VPROH2BC delivers the processing power and reliability required to maintain precise control and system integrity.

Core advantages and technical highlights

High-performance processing: The 1.8 GHz PowerPC processor in the IS215VPROH2BC delivers exceptional computational power, capable of executing 32-bit floating-point operations at speeds up to 3.6 GFLOPS. This enables it to handle complex control logic—such as model predictive control for turbine efficiency optimization—while simultaneously processing thousands of I/O points in real time.

Redundant Ethernet connectivity: Equipped with two gigabit Ethernet ports in a redundant configuration, the module ensures uninterrupted data flow in critical applications. In power plant settings, this redundancy guarantees continuous communication with operator workstations and plant-wide SCADA systems, even if one network path fails, maintaining situational awareness during critical operations.

VxWorks real-time operating system: The embedded VxWorks RTOS provides deterministic response times (≤ 500 µs for priority tasks), essential for time-critical control functions. This stability is particularly valuable in applications like turbine overspeed protection, where microsecond-level response times prevent equipment damage.

Expandable via PMC slot: The integrated PMC slot allows for customized I/O expansion, supporting specialized modules such as high-speed analog input cards or fiber-optic communication interfaces. This flexibility enables the IS215VPROH2BC to adapt to unique application requirements, from high-precision temperature monitoring in chemical plants to high-speed data logging in test facilities.

Rugged design: Built to withstand industrial environments, the module operates reliably in temperatures up to 60°C and resists vibration/shock typical of factory floors or power plant machinery. Its solid-state drive (SSD) eliminates moving parts, reducing failure risks compared to traditional hard drives—critical for applications where unplanned downtime is costly.

Typical application scenarios

In combined-cycle power plants, the IS215VPROH2BC serves as the main controller for coordinating gas and steam turbine operations. It processes data from hundreds of sensors—including exhaust gas thermocouples, steam pressure transducers, and generator current transformers—using advanced algorithms to balance fuel input, steam flow, and electrical output. This synchronization maximizes overall plant efficiency, often increasing output by 2-3% compared to conventional control systems.

In offshore oil and gas platforms, the module controls gas compression trains. It regulates compressor speed, anti-surge valves, and cooling systems based on real-time measurements of gas pressure, flow, and composition. Its rugged design ensures reliable operation in harsh marine environments, where salt spray and vibration would degrade standard industrial computers.

In large-scale manufacturing facilities, the IS215VPROH2BC manages multi-axis motion control for automated production lines. It coordinates robotic arms, conveyor systems, and quality inspection cameras, processing up to 1,000 I/O points per second to maintain precise timing between processes. This level of control reduces production errors by up to 90% in automotive and electronics assembly applications.

GE IS215VPROH2BC

Related model recommendations

GE IS215VPROH1BC: A predecessor to the IS215VPROH2BC with a 1.5 GHz processor, suitable for smaller-scale applications or legacy system upgrades where full processing power isn’t required.

GE IS215IOVHM1A: An analog I/O module that connects to the IS215VPROH2BC via the VMEbus, adding 16 high-precision analog inputs for temperature and pressure measurements.

GE IS215VCMHI2A: A communication module that expands the IS215VPROH2BC‘s connectivity with Profibus and Modbus RTU interfaces, enabling integration with legacy field devices.

GE IS215UCSRH2A: A redundant power supply that pairs with the IS215VPROH2BC, providing 5 VDC backup power to prevent data loss during main supply interruptions.

GE IS215SCCCH2A: A safety controller that works alongside the IS215VPROH2BC to handle SIL 3-rated functions, such as emergency shutdowns, in process industries.

GE IC695PMM330: A PMC-compatible motion control card that plugs into the IS215VPROH2BC‘s expansion slot, adding 8-axis servo control for precision manufacturing applications.

Installation, commissioning and maintenance instructions

Installation preparation: Ensure the VMEbus chassis is powered off before inserting the IS215VPROH2BC. Inspect the backplane connectors for dust or corrosion, cleaning with compressed air if necessary. Use anti-static wrist straps when handling the module to prevent electrostatic damage to the processor and memory components. Verify the 5 VDC power supply is within ±5% tolerance and properly fused (10 A) to avoid voltage spikes during startup.

Commissioning steps: After mounting the IS215VPROH2BC in the VMEbus chassis, power on the system and confirm the front-panel “POWER” LED illuminates green. Use GE’s ToolboxST software to load the control application, configuring network settings (IP addresses, subnet masks) for the Ethernet ports. Test redundancy by disconnecting one Ethernet cable and verifying data continues flowing through the second port. Validate processing performance by simulating maximum I/O load—ensure response times remain below 1 ms for critical control loops.

Maintenance suggestions: Perform monthly visual inspections to check for loose connectors or overheating (indicated by discolored components). Monitor SSD health via the module’s built-in diagnostics—replace if wear indicators exceed 90%. Update firmware quarterly using GE’s secure update utility to address security patches and performance improvements. In case of faults, use the front-panel “FAULT” LED and ToolboxST error logs to diagnose issues. Replace with a genuine IS215VPROH2BC to maintain VMEbus compatibility and system certification.

Service and guarantee commitment

GE backs the IS215VPROH2BC with a 3-year warranty covering manufacturing defects and premature failures under normal operating conditions. Their global technical support team provides 24/7 assistance, offering remote diagnostics via secure VPN connections to minimize downtime. For critical installations, GE engineers can perform on-site commissioning, including control loop tuning and safety validation.

Customers gain access to GE’s online portal with technical manuals, firmware updates, and training videos specific to the IS215VPROH2BC. Extended warranty options (up to 5 years) include annual preventive maintenance checks, where certified technicians verify processor performance, memory integrity, and communication reliability. GE’s commitment to quality ensures the IS215VPROH2BC delivers consistent performance in the most demanding industrial environments.