Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | GE IS215UCVFH2A |

| Manufacturer | General Electric (GE) |

| Product Category | VME Digital I/O Module |

| Series | Mark VI Speedtronic |

| I/O Channels | 16 digital input channels + 16 digital output channels |

| Input Signal Type | 24V DC (sinking/sourcing, configurable) |

| Output Signal Type | 24V DC relay output (3A per channel, 8A per module) |

| Isolation Rating | 2kVrms (channel-to-channel, channel-to-backplane) |

| Communication Interface | Mark VI VME backplane + 1x IONet 10Base2 (BNC) |

| Operating Temperature Range | -40°C to +70°C |

| Power Supply | +5V DC (logic) / +24V DC (relay, external) |

| Installation Method | Mark VI standard VME 6U chassis slot mounting |

| Safety Certifications | CE, UL 508, IEC 61010-1 |

| Physical Size | 10.16 cm (W) × 22.86 cm (H) × 12.7 cm (D) |

| Product Origin | USA |

| Warranty Period | 12 months |

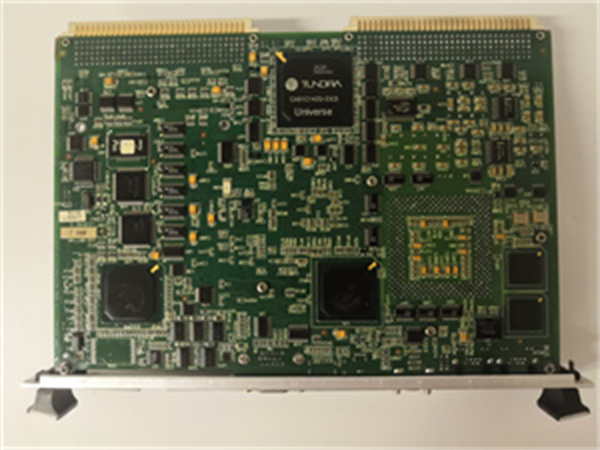

GE IS215UCVFH2A

Product Introduction

The GE IS215UCVFH2A is a high-channel-density VME digital I/O module belonging to GE’s Mark VI Speedtronic series, specifically engineered for medium-to-large industrial control systems requiring reliable discrete signal acquisition and multi-actuator control. As a core front-end and execution component in Mark VI-based architectures, it collects digital status data from field devices (such as limit switches, proximity sensors, and safety interlocks) and outputs relay control signals to mid-power actuators (like solenoid valves, motor contactors, and indicator panels), transmitting data to/from the main controller via the VME backplane and IONet network—ensuring seamless interaction between the control system and distributed field equipment.

Equipped with 16 configurable digital input channels and 16 relay output channels, the GE IS215UCVFH2A integrates advanced signal conditioning, galvanic isolation, and high-reliability relay driving in a standard VME 6U form factor. Its input channels support both sinking and sourcing 24V DC signals, adapting to diverse sensor wiring configurations, while the output channels use industrial-grade electromechanical relays with 3A per-channel current capacity—suitable for direct control of common industrial actuators. In practical applications, the GE IS215UCVFH2A acts as a “distributed control hub” of the Mark VI system, enabling centralized monitoring and control of multiple equipment clusters—balancing channel density, operational reliability, and system scalability for mid-to-large control scenarios.

Core Advantages and Technical Highlights

High-Channel-Density Integration

The GE IS215UCVFH2A features 32-channel (16 in + 16 out) integration within a single VME 6U slot, maximizing I/O density per chassis and reducing system footprint—critical for space-constrained control cabinets in power plants, refineries, or manufacturing facilities. This high-density design eliminates the need for multiple low-channel modules, simplifying system architecture and reducing wiring complexity. Each input channel can be independently configured via GE’s Proficy Machine Edition software (no hardware jumpers required), allowing on-site adjustment to match sinking/sourcing sensors without module replacement. The 16 relay outputs offer a total module current capacity of 8A, supporting parallel control of multiple mid-power actuators while maintaining load balance.

Industrial-Grade Relay Reliability

The GE IS215UCVFH2A uses industrial-grade electromechanical relays with a mechanical life of over 100,000 operations and electrical life of 10,000 operations at full 3A load—ensuring long-term stable switching in harsh industrial environments. Each relay output is equipped with surge suppression diodes to protect against voltage transients caused by inductive loads (e.g., solenoid valves), preventing module damage and signal distortion. The relays also feature visible contact status indicators on the front panel, enabling quick visual verification of output state during maintenance—reducing troubleshooting time for field technicians.

Dual-Interface Communication

The GE IS215UCVFH2A integrates both Mark VI VME backplane and IONet 10Base2 (BNC) communication interfaces, enabling flexible data transmission in distributed control systems. The VME backplane ensures high-speed, deterministic communication with the local Mark VI controller, while the IONet interface allows remote data exchange with other I/O racks or upper-level monitoring systems—ideal for large-scale control architectures where equipment is geographically dispersed. The module supports auto-discovery by the Mark VI controller and IONet network, significantly reducing commissioning time and configuration errors. It also integrates with GE’s Proficy Machine Edition for unified channel mapping, status monitoring, and diagnostic logging.

Typical Application Scenarios

Power Plant Auxiliary System Control

In coal-fired power plant auxiliary systems (e.g., coal handling, ash removal), the GE IS215UCVFH2A serves as the core digital control module. Its 16 digital inputs connect to limit switches (conveyor belt position, hopper level), photoelectric sensors (coal flow detection), and emergency stop buttons. The 16 relay outputs control conveyor motor contactors, gate valves, vibratory feeders, and alarm lights. When the Mark VI controller receives a “start coal feeding” command, it sends signals via the VME backplane to the GE IS215UCVFH2A, which sequentially activates the vibratory feeder, verifies coal flow via input, then starts the main conveyor—ensuring safe and efficient coal supply to the boiler. The IONet interface transmits real-time status data to the central control room, enabling remote monitoring of the auxiliary system.

Automotive Assembly Line Control

In automotive body assembly lines, the GE IS215UCVFH2A controls a section of welding robots and material handling equipment. Its input channels connect to proximity sensors (vehicle body position), limit switches (robot arm home position), and safety light curtains. The output channels control welding gun solenoids, robot grippers, conveyor drives, and station status indicators. When a vehicle body enters the station (input triggered), the GE IS215UCVFH2A receives a command from the Mark VI controller to activate the robot gripper, position the welding gun, verify alignment via inputs, then initiate welding—ensuring precise and repeatable assembly operations. The module’s high channel density reduces the number of modules needed per station, simplifying line architecture and lowering maintenance costs.

GE IS215UCVFH2A

Related Model Recommendations

GE IS215VCMIH2B: A VME bus master controller that pairs with the GE IS215UCVFH2A to process I/O data and execute control logic in the Mark VI system.

GE IS215UCVFH1A: A compact variant with 8 input + 8 output channels, suitable for small-scale control needs alongside the GE IS215UCVFH2A.

GE IS220UCSAH1A: An analog input module that complements the GE IS215UCVFH2A by adding temperature/pressure acquisition for comprehensive process monitoring.

GE IS220PCAAH1A: A VME bus power supply module that provides stable +5V DC logic power to the GE IS215UCVFH2A.

GE IS215VPROH2B: A communication module that works with the GE IS215UCVFH2A to relay data to upper-level SCADA systems via Modbus TCP.

GE IS220YDIAS1A: A supplementary 32-channel digital input module, expanding input capacity for large-scale sensor networks.

GE IS220TRLYH1B: A 24-channel digital output module, enhancing output capacity for extensive actuator clusters.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE IS215UCVFH2A, power off the Mark VI VME chassis and ensure the workspace is ESD-protected (grounded mats/wristbands). Required tools include a Phillips screwdriver, multimeter, torque wrench (0.5 N·m), and wire crimping tool. Verify the chassis slot supports VME 6U standards and prepare an external +24V DC power supply for relays. Align the module’s edge connectors with the slot guides, insert firmly until seated, and secure with front-panel screws. For wiring, use 16AWG-22AWG shielded cables; connect input signals to terminal blocks 1-16, output relays to 17-32, external 24V DC to the power terminal, and IONet BNC cable to the dedicated port. Configure input modes (sinking/sourcing) and IONet parameters via Proficy Machine Edition before powering on the chassis and external relay power.

Maintenance Suggestions

Conduct monthly inspections of the GE IS215UCVFH2A to check LED statuses (Power, Fault, IONet Activity, Input/Output) and terminal block connections—focus on relay output terminals for loose wiring or corrosion. Test input channels quarterly using a 24V DC signal generator to verify status detection, and test output relays with a multimeter to confirm contact continuity. Clean the module’s ventilation slots quarterly with compressed air (≤0.5MPa). If a fault occurs, first check external 24V DC power, IONet cable continuity, and sensor/actuator wiring; use Proficy Machine Edition to view channel-specific diagnostic logs (e.g., relay short-circuit alarms). Replace with genuine GE spares (lead time 2-3 days) and reconfigure I/O parameters to match the original setup—restoring operation quickly.

Service and Guarantee Commitment

The GE IS215UCVFH2A comes with a 12-month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team provides 24/7 assistance via email and online portals, offering guidance on I/O configuration, IONet network setup, and relay troubleshooting. For critical applications, certified GE engineers can be dispatched to customer sites within 48 hours in major industrial regions.

Extended warranty plans up to 3 years are available, including annual preventive maintenance checks and relay contact testing. GE also offers customized training on distributed digital I/O system design and GE IS215UCVFH2A integration with Mark VI systems. With decades of expertise in industrial control and discrete signal management, GE stands behind the reliability of the GE IS215UCVFH2A and is committed to supporting customers throughout the product’s lifecycle.