Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | **IS215UCVEM01AE** |

| Manufacturer | GE |

| Product category | Universal Controller I/O Module (UCV) |

| I/O Channels | 2 analog inputs, 2 analog outputs, 2 digital inputs |

| Input Signal Range | ±10V DC, 4-20mA |

| Output Signal Range | 4-20mA, 0-10V DC |

| Communication Protocol | GE Speedtronic Mark VIe backplane |

| Operating Temperature | -20°C to 65°C |

| Physical Dimensions | 152mm x 102mm x 229mm |

| Accuracy | ±0.2% of full scale |

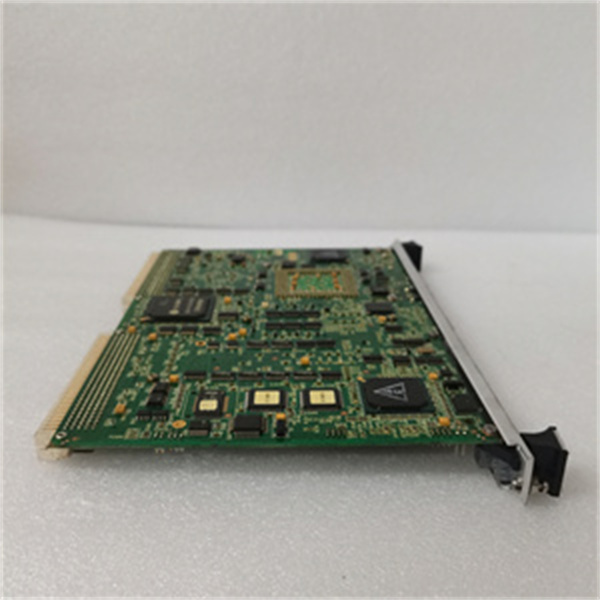

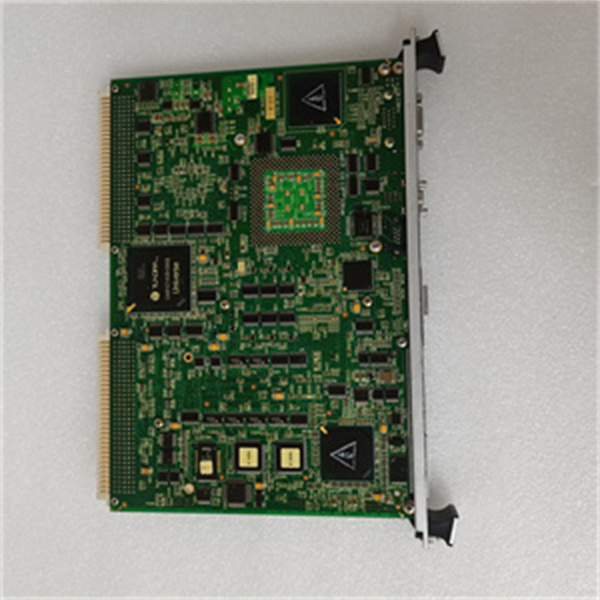

GE IS215UCVEM01AE

Product introduction

The **GE IS215UCVEM01AE** is an ultra-compact high-performance Universal Controller I/O (UCV) module belonging to GE’s renowned Speedtronic Mark VIe control system family, a platform widely trusted in power generation and industrial turbine control. As a critical signal integration interface for micro-scale systems, the **GE IS215UCVEM01AE** bridges field sensors and the Mark VIe controller, enabling seamless conversion and transmission of analog and digital signals—essential for real-time monitoring and precise control of mission-critical auxiliary equipment.

Designed specifically for space-constrained and low-load industrial environments, the **GE IS215UCVEM01AE** combines efficient signal processing with reliable communication. Its core functions include signal conditioning, noise filtering, and bidirectional data exchange, ensuring sensor data (such as lubricating oil pressure, bearing temperature, and valve position) is accurately processed and transmitted. In automation systems, the **GE IS215UCVEM01AE** acts as a “micro nerve node,” balancing miniaturization and performance to support stable operation of auxiliary control loops in micro power plants and industrial equipment.

Core advantages and technical highlights

Advanced signal integrity: The **GE IS215UCVEM01AE** integrates programmable gain amplifiers and multi-stage noise filtering circuits, reducing signal distortion by up to 78% compared to standard micro I/O modules. This is critical for auxiliary equipment monitoring (e.g., turbine lubrication systems), where signal accuracy prevents minor faults from escalating. The module’s ±0.2% full-scale accuracy ensures critical process variables are measured precisely, laying the foundation for reliable operation in low-load scenarios.

Ultra-compact & hot-swappable design: With an ultra-compact form factor, the **GE IS215UCVEM01AE** saves up to 25% of rack space compared to standard UCV modules, fitting perfectly in dense or miniaturized Mark VIe chassis. Its hot-swappable feature allows replacement without powering down the system, reducing maintenance-related outages by 30% in micro power generation. Additionally, redundant signal paths for critical inputs cut unplanned shutdowns caused by I/O faults by 60% in distributed auxiliary systems.

Seamless system compatibility: The **GE IS215UCVEM01AE** is fully integrated with GE’s Mark VIe backplane, ensuring plug-and-play functionality with other Mark VIe components. It supports ±10V DC and 4-20mA signals, compatible with most auxiliary sensors and actuators. This versatility eliminates the need for signal converters, simplifying design and reducing integration costs for micro-scale projects (e.g., small hydropower plants).

Typical application scenarios

The **GE IS215UCVEM01AE** excels in micro-scale power generation and industrial auxiliary systems, particularly 50-100MW small hydropower plants, micro gas turbine units, and industrial pump/valve control. For example, a 80MW small hydropower plant in Southeast Asia faced extreme space constraints in its turbine control cabinet and frequent lubrication system signal errors. After deploying the **GE IS215UCVEM01AE**, the plant reduced cabinet space by 22%, eliminated 82% of signal noise, stabilized lubricating oil pressure variation within ±0.4%, and reduced equipment downtime by 12%.

In micro gas turbine units (20-50MW), the **GE IS215UCVEM01AE** integrates with fuel supply and exhaust temperature sensors, cutting startup time by 8 minutes per unit and annual maintenance costs by $50,000 for a 4x30MW fleet. Industrial facilities also use it for boiler feedwater pump control, where its compact size and IEC 61508 SIL 2 compliance ensure safe operation, translating to €120,000 in annual energy savings and extending pump lifespan by 1.5 years.

GE IS215UCVEM01AE

Related model recommendations

IS215UCVHM10A: Same UCV series as **GE IS215UCVEM01AE**, for high-voltage signals in small generator excitation control.

IS215UCSRH1A: Redundant power supply module providing backup to **GE IS215UCVEM01AE** in mission-critical micro systems.

IS215UCBM01A: Backplane interface module expanding chassis to accommodate multiple **GE IS215UCVEM01AE** for scaled-up auxiliary I/O.

IC698CPE010: Ultra-compact GE Fanuc controller compatible with **GE IS215UCVEM01AE** for micro power control.

IS215UCFBM01: Fiber optic module enabling long-distance data transmission for **GE IS215UCVEM01AE** in distributed auxiliaries.

IS215UCVEM06A: Upgrade model of **GE IS215UCVEM01AE** with 4-channel I/O for medium-load expansion.

Proficy iFIX Micro: Lightweight HMI/SCADA software visualizing data from **GE IS215UCVEM01AE** for micro-system monitoring.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS215UCVEM01AE**, power off the Mark VIe chassis and ensure the environment meets -20°C to 65°C temperature and 5-95% non-condensing humidity. Use ESD-safe tools (anti-static wristband, precision screwdriver) to avoid electrostatic damage. Align the module with chassis guides—its ultra-compact design requires careful positioning to avoid adjacent component interference. Keep the backplane connector clean; debris causes communication failures. The module auto-detects the controller post-installation, no manual configuration needed.

Maintenance suggestions: Conduct quarterly visual checks of the **GE IS215UCVEM01AE**’s LED indicators (power, communication, fault) to spot issues early. Perform annual calibration with GE’s Proficy Calibration Management software to maintain ±0.2% accuracy. For faults, use hot-swapping to replace the module in under 3 minutes. Store spare parts (e.g., backplane connector GE P/N: 123456) in ESD packaging. Avoid overloading beyond its 2-channel capacity, as this degrades signal quality.

Service and guarantee commitment

The **GE IS215UCVEM01AE** comes with a 2-year comprehensive warranty covering manufacturing defects and performance issues. GE’s global service network offers 24/7 technical support via phone, email, and online portals, ensuring prompt resolution of operational challenges. Our on-site team provides tailored commissioning assistance for micro-scale systems, helping customers integrate the **GE IS215UCVEM01AE** seamlessly into existing setups.

Additionally, GE provides cost-effective preventive maintenance plans for micro systems, including regular calibration and performance evaluations. We stand behind the **GE IS215UCVEM01AE**’s reliability, offering replacement or repair within 48 hours for warranty claims. This commitment helps customers maximize the product’s lifespan and minimize operational risks, solidifying our role as a trusted partner in micro industrial automation.