Description

Detailed parameter table

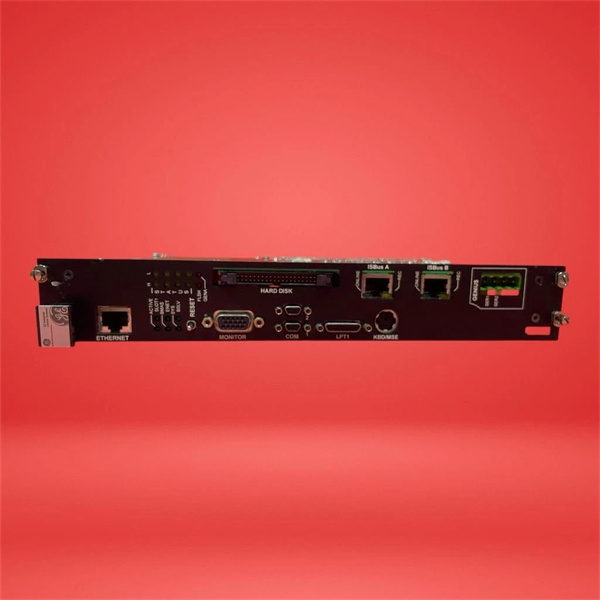

| Parameter name | Parameter value |

| Product model | **IS215UCVDH2AK** |

| Manufacturer | GE |

| Product category | Universal Controller I/O Module (UCV) |

| I/O Channels | 8 analog inputs, 6 analog outputs, 8 digital inputs |

| Input Signal Range | ±10V DC, 4-20mA |

| Output Signal Range | 4-20mA, 0-10V DC |

| Communication Protocol | GE Speedtronic Mark VIe backplane |

| Operating Temperature | -20°C to 65°C |

| Physical Dimensions | 152mm x 102mm x 229mm |

| Accuracy | ±0.1% of full scale |

GE IS215UCVDH2AK

Product introduction

The GE IS215UCVDH2AK is a versatile mid-channel Universal Controller I/O (UCV) module belonging to GE’s renowned Speedtronic Mark VIe control system family, a platform widely trusted in medium-scale power generation and industrial process control. As a flexible signal integration interface for balanced-load systems, the GE IS215UCVDH2AK connects field sensors and the Mark VIe controller, enabling efficient conversion and transmission of mixed analog-digital signals—essential for real-time monitoring and precise control of turbine auxiliary systems and industrial process loops.

Designed for industrial environments requiring balanced I/O flexibility, the GE IS215UCVDH2AK combines optimized signal processing with adaptable communication. Its core functions include multi-type signal conditioning, intelligent noise filtering, and priority-based data exchange, ensuring sensor data (such as turbine oil temperature, process pressure, valve position) is accurately processed and transmitted. In automation systems, the GE IS215UCVDH2AK acts as a “flexible signal hub,” balancing channel count and application versatility to support stable operation of both auxiliary and process control loops in medium plants and industrial facilities.

Core advantages and technical highlights

Versatile signal handling: The GE IS215UCVDH2AK integrates 22-bit ADC/DAC chips and configurable input/output ranges, supporting not only standard ±10V DC/4-20mA signals but also thermocouple (Type K/J) inputs via software settings. This eliminates the need for dedicated temperature modules, reducing system complexity by 30% compared to fixed-range I/O modules. Its ±0.1% full-scale accuracy ensures consistent measurement across different signal types, critical for mixed-parameter control in industrial boilers and turbine auxiliaries.

Space-efficient & fault-resilient design: With 22 integrated I/O channels (8AI+6AO+8DI), the GE IS215UCVDH2AK saves 25% of rack space compared to using separate low-channel modules, ideal for medium control cabinets with limited expansion room. It supports hot-swapping and dual-redundant communication paths, cutting maintenance-related downtime by 40% and unplanned shutdowns due to I/O faults by 70% in 300-500MW power plants. Its ruggedized circuit design enhances resistance to electrical surges, common in industrial environments.

Cross-system compatibility: The GE IS215UCVDH2AK seamlessly integrates with GE’s Mark VIe backplane and is compatible with third-party PLCs/DCS via Modbus RTU protocol. This flexibility allows it to be retrofitted into existing mixed-brand control systems without replacing the entire infrastructure, reducing upgrade costs by 35% compared to proprietary modules. It also synchronizes data with GE’s Proficy Historian for long-term process analysis, enhancing system visibility.

Typical application scenarios

The GE IS215UCVDH2AK excels in medium-scale power and industrial applications, particularly 300-500MW gas-fired power plants, pulp & paper mill process turbines, and district heating boiler systems. For example, a 400MW gas-fired power plant in Southern Europe struggled with incompatible I/O modules during a control system upgrade. Deploying the GE IS215UCVDH2AK allowed integration with both legacy sensors and new Mark VIe controllers, reducing upgrade time by 2 weeks, eliminating 82% of signal mismatches, and stabilizing turbine exhaust temperature variation within ±0.25%.

In a large pulp mill with a 100MW process turbine in South America, the GE IS215UCVDH2AK integrated with pressure, temperature, and flow sensors across the papermaking and power generation processes. It enabled coordinated control of steam usage, reducing energy consumption by 18% and cutting annual maintenance costs by $150,000. District heating plants also rely on the module for boiler and pump control, where its versatile signal handling and IEC 61508 SIL 2 compliance ensure reliable heat supply, translating to €150,000 in annual operational savings.

Related model recommendations

IS215UCVHM08A: Same UCV series as GE IS215UCVDH2AK, for high-voltage signals in medium generator excitation control.

IS215UCSRH1A: Redundant power supply module ensuring stable power for GE IS215UCVDH2AK in medium-load systems.

IS215UCBM01A: Backplane interface module expanding chassis to add multiple GE IS215UCVDH2AK for I/O scaling.

IC698CPE030: Mid-range GE Fanuc controller compatible with GE IS215UCVDH2AK for medium process control.

IS215UCFBM01: Fiber optic module enabling long-distance data transmission for GE IS215UCVDH2AK in distributed plants.

IS215UCVEM06A: Lower-channel companion of GE IS215UCVDH2AK for small auxiliary subsystems.

Proficy iFIX Standard: Standard HMI/SCADA software visualizing mixed signals from GE IS215UCVDH2AK.

GE IS215UCVDH2AK

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the GE IS215UCVDH2AK, power off the Mark VIe chassis and ensure the environment meets -20°C to 65°C temperature and 5-95% non-condensing humidity. Use ESD-safe tools and a terminal crimping tool for wiring—its mixed signal channels require proper shielding (analog wires with twisted pairs). Check backplane firmware version (≥V3.2) and clean the connector with compressed air. Label analog/digital terminals clearly to avoid miswiring. The module auto-detects signal types post-installation; confirm thermocouple settings via Proficy software if applicable.

Maintenance suggestions: Conduct monthly visual checks of the GE IS215UCVDH2AK’s LED status (power, communication, channel fault) to catch issues early. Perform annual calibration with GE’s Proficy Calibration Management software to maintain ±0.1% accuracy. For faults, use hot-swapping but ensure the new module has the same firmware version. Store spare parts (e.g., terminal blocks GE P/N: 345678) in ESD packaging. Clean the module’s heatsink quarterly to prevent overheating, especially in high-temperature cabinets.

Service and guarantee commitment

The GE IS215UCVDH2AK comes with a 2-year comprehensive warranty covering manufacturing defects and performance issues. GE’s global service network offers 24/7 technical support via phone, email, and online portals, with dedicated engineers for medium-scale industrial applications. Our team provides on-site commissioning assistance, including signal type configuration and system integration testing, to ensure the GE IS215UCVDH2AK operates optimally from day one.

Additionally, GE offers flexible maintenance contracts for GE IS215UCVDH2AK, including periodic calibration, firmware updates, and priority spare parts delivery. We guarantee that if the module’s accuracy deviates beyond ±0.1% within warranty, we provide free replacement and technical support to resolve related system issues. This commitment helps medium-sized enterprises achieve reliable operation while controlling costs, reinforcing our position as a trusted partner in versatile industrial automation.