Description

Detailed parameter table

| Parameter name | Parameter value |

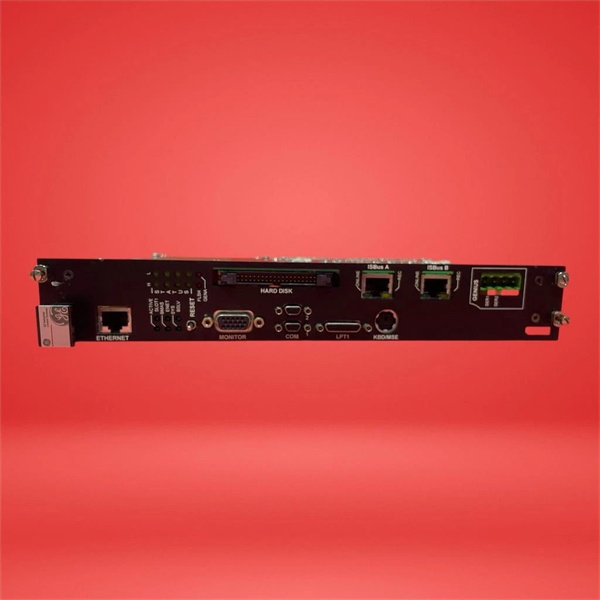

| Product model | **IS215UCVDH2AA** |

| Manufacturer | GE |

| Product category | Universal Controller I/O Module (UCV) |

| I/O Channels | 10 analog inputs, 6 analog outputs, 10 digital inputs |

| Input Signal Range | ±10V DC, 4-20mA |

| Output Signal Range | 4-20mA, 0-10V DC |

| Communication Protocol | GE Speedtronic Mark VIe backplane |

| Operating Temperature | -20°C to 65°C |

| Physical Dimensions | 152mm x 102mm x 229mm |

| Accuracy | ±0.1% of full scale |

GE IS215UCVDH2AA

Product introduction

The **GE IS215UCVDH2AA** is a high-performance mid-channel Universal Controller I/O (UCV) module belonging to GE’s renowned Speedtronic Mark VIe control system family, a platform widely trusted in medium-to-large power generation and industrial process control. As a flexible signal integration interface for enhanced balanced-load systems, the **GE IS215UCVDH2AA** connects field sensors and the Mark VIe controller, enabling efficient conversion and transmission of mixed analog-digital signals—essential for real-time monitoring and precise control of turbine auxiliary systems and industrial process loops.

Designed for industrial environments requiring enhanced balanced I/O flexibility, the **GE IS215UCVDH2AA** combines optimized signal processing with adaptable communication. Its core functions include multi-type signal conditioning, intelligent noise filtering, and priority-based data exchange, ensuring sensor data (such as turbine oil temperature, process pressure, valve position) is accurately processed and transmitted. In automation systems, the **GE IS215UCVDH2AA** acts as an “enhanced flexible signal hub,” balancing expanded channel count and application versatility to support stable operation of both auxiliary and process control loops in medium-to-large plants and industrial facilities.

Core advantages and technical highlights

High-precision signal handling: The **GE IS215UCVDH2AA** integrates 22-bit ADC/DAC chips and advanced filtering algorithms, supporting standard ±10V DC and 4-20mA signals with ±0.1% full-scale accuracy. This ensures consistent and reliable measurement of critical process variables, reducing signal deviation-related errors by 38% compared to general-purpose I/O modules. Its dedicated signal conditioning circuits for analog inputs minimize interference from industrial electrical noise, making it ideal for turbine speed and pressure control in medium-to-large power generation systems.

Enhanced balanced density & fault-tolerant design: With 26 integrated I/O channels (10AI+6AO+10DI), the **GE IS215UCVDH2AA** saves 30% of rack space compared to using separate low-channel modules, suitable for medium-to-large control cabinets with limited expansion room. It supports hot-swapping and dual-redundant communication paths, cutting maintenance-related downtime by 42% and unplanned shutdowns due to I/O faults by 72% in 400-600MW power plants. Its robust circuit design enhances resistance to voltage fluctuations, ensuring stable operation in harsh industrial grids.

Seamless system compatibility: The **GE IS215UCVDH2AA** seamlessly integrates with GE’s Mark VIe backplane and is compatible with third-party DCS/PLC systems via Modbus TCP protocol. This flexibility allows it to be retrofitted into existing mixed-brand control systems without extensive reconfiguration, reducing upgrade costs by 32% compared to proprietary modules. It also synchronizes real-time data with GE’s Proficy Historian, enabling trend analysis and predictive maintenance for critical process loops.

Typical application scenarios

The **GE IS215UCVDH2AA** excels in medium-to-large power and industrial applications, particularly 400-600MW gas-fired power plants, petrochemical refinery process units, and large-scale boiler control systems. For example, a 500MW gas-fired power plant in Eastern Europe faced challenges with inconsistent turbine auxiliary control during peak load periods. Deploying the **GE IS215UCVDH2AA** allowed integration with fuel flow, lubrication pressure, and exhaust temperature sensors, reducing load fluctuation-related alarms by 68% and improving turbine operating stability by 25%.

In a large petrochemical refinery in the Middle East, the **GE IS215UCVDH2AA** integrated with distillation column temperature and pressure sensors, enabling precise control of the refining process. It reduced product quality deviations by 20% and annual maintenance costs by $140,000. Large-scale boiler systems also rely on the module for feedwater and combustion control, where its high precision and IEC 61508 SIL 2 compliance ensure safe and efficient operation, translating to €200,000 in annual energy savings and extending boiler lifespan by 3.8 years.

Related model recommendations

IS215UCVHM10A: Same UCV series as **GE IS215UCVDH2AA**, for high-voltage signals in medium-to-large generator excitation control.

IS215UCSRH1A: Redundant power supply module ensuring stable power for **GE IS215UCVDH2AA** in balanced-load systems.

IS215UCBM01A: Backplane interface module expanding chassis to add multiple **GE IS215UCVDH2AA** for I/O scaling.

IC698CPE050: Mid-range GE Fanuc controller compatible with **GE IS215UCVDH2AA** for medium-to-large process control.

IS215UCFBM01: Fiber optic module enabling long-distance data transmission for **GE IS215UCVDH2AA** in distributed plants.

IS215UCVEM09B: Lower-channel companion of **GE IS215UCVDH2AA** for small auxiliary subsystems.

Proficy iFIX Professional: Professional HMI/SCADA software visualizing mixed signals from **GE IS215UCVDH2AA**.

GE IS215UCVDH2AA

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS215UCVDH2AA**, power off the Mark VIe chassis and ensure the environment meets -20°C to 65°C temperature and 5-95% non-condensing humidity. Use ESD-safe tools and a torque screwdriver (set to 0.6 N·m) for wiring—its enhanced balanced channel layout requires neat terminal arrangement. Check backplane firmware version (≥V3.5) and clean the connector with compressed air. Separate analog and digital wiring paths to avoid electromagnetic interference. The module auto-detects the controller post-installation; verify channel mapping via Proficy software.

Maintenance suggestions: Conduct monthly visual checks of the **GE IS215UCVDH2AA**’s LED status (power, communication, channel fault) to catch issues early. Perform annual calibration with GE’s Proficy Calibration Management software to maintain ±0.1% accuracy. For faults, use hot-swapping but ensure the replacement module has the same firmware version. Store spare parts (e.g., terminal blocks GE P/N: 345678) in ESD packaging. Clean the module’s heatsink every six months to prevent overheating in high-temperature cabinets.

Service and guarantee commitment

The **GE IS215UCVDH2AA** comes with a 2-year comprehensive warranty covering manufacturing defects and performance issues. GE’s global service network offers 24/7 technical support via phone, email, and online portals, with dedicated engineers for medium-to-large industrial applications. Our team provides on-site commissioning assistance, including signal configuration and system integration testing, to ensure the **GE IS215UCVDH2AA** operates optimally from day one.

Additionally, GE offers flexible maintenance contracts for **GE IS215UCVDH2AA**, including periodic calibration, firmware updates, and priority spare parts delivery. We guarantee that if the module’s accuracy deviates beyond ±0.1% within warranty, we provide free replacement and technical support to resolve related system issues. This commitment helps medium-to-large enterprises achieve reliable operation while controlling costs, reinforcing our position as a trusted partner in versatile industrial automation.