Description

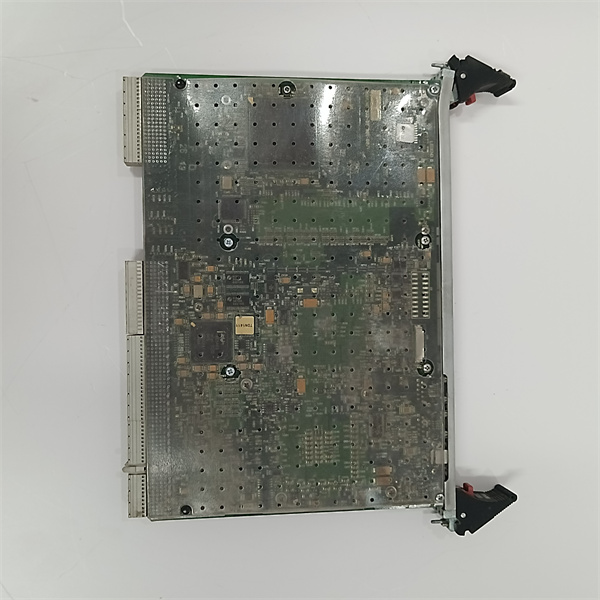

GE IS215UCCCM04A

Detailed parameter table

| Parameter name | Parameter value |

| Product model | IS215UCCCM04A |

| Manufacturer | GE (General Electric) |

| Product category | Processor module for Mark VIe turbine control systems |

| Processor | 1.0 GHz dual-core industrial-grade processor |

| Memory | 1 GB DDR3 RAM, 4 GB flash storage |

| Operating system | Embedded real-time operating system (RTOS) |

| Communication interfaces | 2 x Ethernet (10/100 Mbps) with redundant design, 1 x RS-485 |

| I/O integration | Supports up to 24 digital inputs/outputs and 12 analog channels via expansion |

| Operating temperature | -10°C to +60°C |

| Humidity tolerance | 5% – 95% non-condensing |

| Power supply | 24 VDC ±10%, 12 W typical consumption |

| Physical dimensions | 160 mm x 100 mm x 30 mm (length x width x height) |

| Mounting type | Backplane slot mounting for Mark VIe chassis |

| Certification | UL 508, IEC 61508 (SIL 2), CE marked |

GE IS215UCCCM04A

Product introduction

The GE IS215UCCCM04A is a reliable processor module engineered for GE’s Mark VIe turbine control systems, a key platform in power generation and industrial turbomachinery management. As a central computing component, it acts as the operational core of the control system, executing essential control algorithms, processing real-time sensor data, and synchronizing actions across connected equipment.

This module combines a 1.0 GHz dual-core processor with practical memory capacity, making it well-suited for handling the computational demands of turbine control—including speed regulation, load distribution, and safety interlock management. Its design ensures seamless integration within the Mark VIe ecosystem, working in harmony with I/O modules, communication interfaces, and other system components to form a cohesive control architecture. Whether deployed in gas turbines, steam turbines, or small-scale combined-cycle plants, the IS215UCCCM04A delivers consistent performance and precision, contributing to optimal turbine operation and asset protection.

Core advantages and technical highlights

Dual-core efficiency: The 1.0 GHz dual-core processor in the IS215UCCCM04A enables parallel processing of control logic and data analysis, reducing delays in time-sensitive operations. For instance, it can simultaneously adjust fuel flow based on turbine speed while monitoring temperature sensors for abnormal fluctuations, balancing performance and safety effectively.

Redundant communication design: With two Ethernet ports configured for redundancy, the module minimizes the risk of communication failures. In power generation facilities, this redundancy ensures continuous data transmission to SCADA systems and operator stations, even if one network link is disrupted—vital for maintaining oversight during turbine operation.

Deterministic RTOS: The embedded real-time operating system guarantees predictable response times (≤ 2 ms for critical tasks), essential for turbine control where precise timing prevents overspeed incidents or fuel imbalances. This stability is particularly beneficial during startup, shutdown, and load change sequences.

SIL 2 compliance: Meeting IEC 61508 (SIL 2) standards, the IS215UCCCM04A is qualified for safety-critical functions such as emergency shutdown protocols. It includes built-in diagnostic tools that continuously assess hardware status, issuing alerts for potential issues before they affect system operation.

Scalable I/O support: The module accommodates I/O expansion to adapt to different turbine sizes and setups. A small industrial turbine might utilize 12 digital inputs for limit switches, while a mid-sized steam turbine could require 10 analog channels for pressure and temperature monitoring—all managed efficiently by the IS215UCCCM04A.

Typical application scenarios

In small to medium-sized gas turbine power plants, the IS215UCCCM04A functions as the main controller. It processes data from exhaust gas thermocouples, compressor pressure transducers, and rotor speed sensors. Using this information, it adjusts fuel valves and guide vanes to maintain optimal operating temperatures, balancing efficiency with emission compliance.

In biomass power facilities, the module coordinates turbine operation with fuel feeding systems. It modulates turbine load based on biomass fuel availability and electrical grid demand, ensuring stable power output while preventing fuel supply overloads. Its ability to communicate with plant management systems allows for integration with renewable energy monitoring platforms.

In industrial CHP (Combined Heat and Power) systems, the IS215UCCCM04A manages turbine performance to meet both electrical and thermal requirements. It adjusts operation to prioritize either electricity generation or steam production for on-site processes (e.g., manufacturing heating), optimizing energy use across multiple applications.

GE IS215UCCCM04A

Related model recommendations

GE IS215UCCCM03A: A predecessor to the IS215UCCCM04A with a single-core processor, suitable for smaller turbines or legacy system upgrades where dual-core performance isn’t necessary.

GE IS215UCSRH1A: A redundant power supply module that pairs with the IS215UCCCM04A to provide backup 24 VDC power, enhancing system reliability.

GE IS215IOVHM01A: An analog I/O module that expands the IS215UCCCM04A‘s sensing capabilities, adding 8 high-precision analog inputs for pressure and temperature measurements.

GE IS215VCMHI1A: A communication gateway that connects the IS215UCCCM04A to plant-wide networks, enabling data sharing with enterprise systems for performance analysis.

GE IS215SCCCH1A: A safety controller module that works with the IS215UCCCM04A to manage SIL 3-rated safety functions, such as overspeed protection, in high-risk environments.

Installation, commissioning and maintenance instructions

Installation preparation: Ensure the Mark VIe chassis is powered off before inserting the IS215UCCCM04A into the designated backplane slot. Inspect backplane connectors for cleanliness and debris to avoid communication issues. Use anti-static gloves when handling the module to prevent electrostatic damage. Confirm the 24 VDC power supply is stable and properly fused (1 A) to avoid voltage spikes during startup.

Commissioning steps: After installation, power on the chassis and use GE’s ToolboxST software to load the turbine-specific control program onto the IS215UCCCM04A. Configure network settings (IP address, subnet mask) via the module’s web interface or serial port. Conduct functional tests by simulating key inputs (e.g., turbine speed signals) and verifying correct output responses (e.g., fuel valve adjustment). Test redundancy by disconnecting one Ethernet cable and ensuring data continues to flow through the alternate path.

Maintenance suggestions: Perform quarterly visual inspections to check for loose connections or dust buildup—use compressed air to clean vents if required. Monitor processor load via the operator interface; loads exceeding 75% for extended periods may indicate the need for program optimization. Schedule annual firmware updates using GE’s secure update tool to address bugs and enhance functionality. In case of faults, refer to the module’s diagnostic LED codes (e.g., steady red light indicates power issues) for quick troubleshooting. Always replace with a genuine GE IS215UCCCM04A to maintain system compatibility and safety certifications.

Service and guarantee commitment

GE provides a 2-year warranty for the IS215UCCCM04A, covering manufacturing defects and performance issues under normal operating conditions. Their global technical support team offers 24/7 assistance, including remote diagnostics via secure VPN to minimize downtime. For critical installations, GE offers on-site commissioning services with certified engineers to ensure proper integration and calibration.

Customers also gain access to GE’s online knowledge base and training resources, designed to improve user proficiency with the module and Mark VIe systems. Extended warranty options (up to 5 years) include predictive maintenance checks using GE’s Asset Performance Management (APM) software, which analyzes module health data to predict potential issues. This comprehensive support ensures the IS215UCCCM04A delivers reliable performance throughout its operational life.