Description

Detailed Parameter Table

| Parameter name | Parameter value |

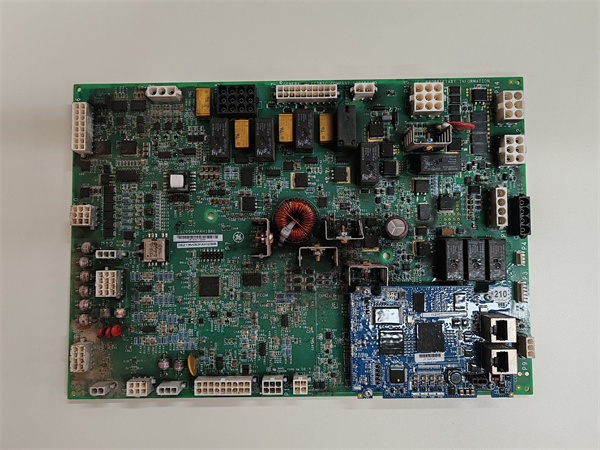

| Product model | IS210BPPCH1AD |

| Manufacturer | GE (General Electric) |

| Product category | I/O Pack Processor Board |

| Series compatibility | Mark VIe Turbine Control System |

| Voltage range | 9 – 16 VDC (Nominal: 12 VDC) |

| Interface type | Serial interfaces (compatible with various sensors and actuators in the Mark VIe system) |

| Configuration support | Simplex, Dual, or Triple Modular Redundant (TMR) configurations |

| Diagnostic support | Supports diagnostic signals to UCPA (Unit Control Processor Assembly) |

| LED status indication | Features red and green LEDs for status monitoring; 7 patterns for red attention and 4 patterns for green attention |

| Processor board compatibility | Compatible with components like YAI CS 1B, Y DIAS 1B, Y DO AS 1B, PVI BH 1B, Y VIBS 1B, etc. |

| Auto – reconfiguration | Supports auto – reconfiguration from BPPB to BPPCH1AD (except in certain circumstances) |

| Reset features | Equipped with reset circuits and a hardware watchdog timer |

| Software support | Supports ToolboxST application for marking code sets |

| Dimensions | [Specify if available, e.g., length x width x height in mm] |

| Weight | [Specify if available in kg or g] |

| Operating temperature | 0°C – 60°C (approximate, may vary; confirm with official GE documentation) |

| Storage temperature | – 40°C – 85°C (approximate, may vary; confirm with official GE documentation) |

GE IS210BPPCH1AD

Product Introduction

The GE IS210BPPCH1AD is a highly specialized I/O Pack Processor Board meticulously engineered for seamless integration within General Electric’s Mark VIe Turbine Control System. This board serves as a critical link in the complex network of components that govern the operation of gas, steam, and wind turbine automated drive assemblies.

Designed with precision, the IS210BPPCH1AD processes and manages input and output signals, ensuring efficient communication between various field devices (such as sensors and actuators) and the central control system. Its ability to handle a wide range of serial interfaces, combined with a nominal operating voltage of 12 VDC, makes it adaptable to different electrical requirements within the Mark VIe ecosystem.

As part of the IS210 special assembly, this board has been tailored to meet the specific operational demands of the Mark VIe series. It features local CPU power supplies, providing reliable power to the onboard processing components. The red and green LEDs offer a quick visual indication of the board’s status, with distinct flashing patterns for attention – grabbing alerts.

Core Advantages and Technical Highlights

Flexible configuration options: The IS210BPPCH1AD can be deployed in simplex, dual, or triple modular redundant (TMR) configurations. In a large – scale power generation plant with multiple gas turbines, a TMR configuration using the IS210BPPCH1AD ensures high availability. If one board fails in the TMR setup, the other two can continue to operate, minimizing the risk of turbine shutdowns and power outages. This flexibility allows system integrators to design control systems that match the specific reliability requirements of different industrial applications.

Diagnostic and monitoring capabilities: With its support for diagnostic signals to the UCPA, the IS210BPPCH1AD enables proactive maintenance. In a wind farm, for example, the board can continuously monitor the performance of wind turbines. If it detects any anomalies in the sensor data (such as abnormal vibration levels or temperature fluctuations), it can send diagnostic signals to the UCPA. Technicians can then use this information to identify and address potential issues before they lead to turbine failures, reducing maintenance costs and downtime.

Auto – reconfiguration functionality: The board’s ability to support auto – reconfiguration from BPPB to BPPCH1AD (where applicable) simplifies system upgrades and component replacements. In an industrial facility where the control system is being updated, the IS210BPPCH1AD can automatically adjust its settings to integrate with the existing infrastructure. This reduces the need for extensive manual re – programming and configuration, saving time and minimizing the risk of human – error during system changes.

Reliable power management: The local CPU power supplies on the IS210BPPCH1AD ensure stable power delivery to the board’s processing components. In industrial environments where power fluctuations are common, such as in manufacturing plants with large – scale machinery, this feature protects the board from voltage sags and surges. The hardware watchdog timer and reset circuits further enhance the board’s reliability by automatically resetting the board in case of software glitches or system freezes, ensuring continuous operation.

Typical Application Scenarios

Power generation – gas turbines: In a natural gas – fired power plant, the IS210BPPCH1AD plays a crucial role in controlling the gas turbine. It interfaces with sensors that measure parameters like fuel flow, combustion temperature, and turbine speed. Based on the processed sensor data, the board sends control signals to actuators such as fuel valves and variable – geometry turbines. This precise control ensures optimal combustion efficiency, maximizing power output while minimizing fuel consumption and emissions.

Power generation – steam turbines: In a coal – fired power plant with steam turbines, the IS210BPPCH1AD is used to manage the steam turbine’s operation. It monitors steam pressure, temperature, and flow rate, and controls the opening and closing of steam valves. By maintaining the correct steam conditions, the board helps to ensure smooth turbine operation and efficient power generation. In case of any abnormal conditions, the board’s diagnostic capabilities can quickly identify the problem and initiate appropriate corrective actions.

Renewable energy – wind turbines: In a wind farm, the IS210BPPCH1AD is responsible for monitoring and controlling wind turbines. It receives data from sensors that measure wind speed, direction, and blade pitch. The board then processes this data to adjust the blade pitch and turbine speed, optimizing power generation based on the changing wind conditions. Its ability to operate in harsh environmental conditions, combined with its diagnostic and monitoring features, makes it suitable for use in remote wind farms where maintenance access may be limited.

GE IS210BPPCH1AD

Related Model Recommendations

GE IS210BPPCH1AC: Another I/O Pack Processor Board in the Mark VIe series. It has similar functionality to the IS210BPPCH1AD but may have slight differences in component tolerances or firmware versions. In a system where redundancy is crucial, both the IS210BPPCH1AD and IS210BPPCH1AC can be used in a redundant configuration to further enhance system reliability.

GE IS200 series boards: Some boards from the IS200 series can be used in conjunction with the IS210BPPCH1AD. For example, certain I/O modules in the IS200 series can provide additional input or output channels, expanding the system’s capabilities. In a large – scale industrial control system, a combination of IS210BPPCH1AD and IS200 series boards can be used to create a comprehensive and flexible control solution.

GE ToolboxST software suite: This software is essential for configuring and managing the IS210BPPCH1AD. It allows users to set up the board’s parameters, monitor its status, and perform diagnostic tests. The software’s intuitive interface makes it easy for technicians to work with the board, even for those with limited experience in turbine control systems.

GE YAI CS 1B, Y DIAS 1B, Y DO AS 1B, PVI BH 1B, Y VIBS 1B components: These components are compatible with the IS210BPPCH1AD. In a complete turbine control system, they can work together to perform specific functions. For instance, the YAI CS 1B may be used for analog input conversion, while the IS210BPPCH1AD processes and distributes the converted data to other parts of the system.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the GE IS210BPPCH1AD, ensure that the Mark VIe Turbine Control System is powered down. Verify that the installation area is clean, free from dust, and has proper ventilation. Check the voltage of the power supply to ensure it falls within the 9 – 16 VDC range (nominal 12 VDC). Use anti – static tools and wear an anti – static wristband to prevent electrostatic discharge (ESD) damage to the board. If replacing an existing board, carefully note the connections and configurations of the old board.

Commissioning: After installing the board, power up the Mark VIe system. Use the GE ToolboxST software to configure the IS210BPPCH1AD. Set the appropriate parameters for the board’s operation, such as its communication settings, input/output configurations, and diagnostic options. Calibrate any sensors or actuators connected to the board if required. Monitor the board’s status LEDs to ensure that it is operating correctly. If any error messages are displayed, refer to the GE documentation or contact technical support for troubleshooting.

Maintenance suggestions: Regularly perform visual inspections of the IS210BPPCH1AD to check for any signs of physical damage, such as cracks or burn marks. Look for loose connections or signs of overheating, like discolored components. Use the ToolboxST software to periodically check the board’s diagnostic data for any anomalies. Clean the board using compressed air to remove dust and debris, especially from ventilation slots. If a component on the board fails, follow the proper procedures for replacement. Back up the board’s configuration data regularly to prevent data loss in case of a board failure.

Service and Guarantee Commitment

GE offers a [specify warranty period, e.g., 12 – month] warranty for the GE IS210BPPCH1AD, covering manufacturing defects and component failures under normal operating conditions. The company’s global technical support team is available to assist customers with any technical issues. They can be reached via phone, email, or online chat. For more complex problems, on – site service can be arranged in major industrial regions.

Customers can access a range of resources, including user manuals, technical documentation, and firmware updates (if applicable), through GE’s industrial support portal. Training courses may be available to help technicians and system integrators understand the installation, configuration, and maintenance of the IS210BPPCH1AD. For critical applications, GE may offer extended warranty plans that include priority support and preventive maintenance services, ensuring the long – term reliable operation of the board.