Description

Parameter table for IS210BPPCH1AD

| Parameter name | Parameter value |

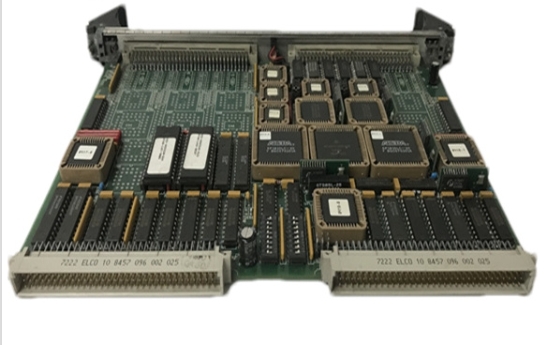

| Product model | IS210BPPCH1AD |

| Manufacturer | General Electric (GE) |

| Product category | I/O Pack Processor Board, integral to the Mark VIe Turbine Control System |

| Dimensions (approx.) | Compact design suitable for installation within the control system’s enclosure; specific dimensions available in the product manual |

| Weight | Lightweight, facilitating easy handling and integration within the system |

| Processor | Specialized processor optimized for handling I/O operations and data processing related to turbine control |

| Memory | Adequate memory for storing configuration data, control algorithms relevant to I/O handling, and real – time data from connected devices |

| I/O interfaces | Multiple interfaces designed to connect with various input and output devices within the turbine control setup, ensuring seamless data transfer |

| Communication protocols | Supports communication protocols specific to the Mark VIe Turbine Control System, enabling effective data exchange with other system components |

| Power supply | Operates within a voltage range of 9 – 16 VDC, with a nominal voltage of 12 VDC; equipped with power regulation features to handle voltage fluctuations |

| Operating temperature range | Designed to function reliably in temperatures ranging from – 10°C to + 55°C, suitable for typical industrial control environments |

| Environmental resistance | Resistant to electromagnetic interference (EMI) and vibration, ensuring stable operation in the presence of electrical noise and mechanical vibrations common in industrial settings |

| Diagnostic functions | Equipped with diagnostic features that can detect faults in I/O operations, power supply issues, and communication problems; provides visual status through LED indicators |

| Configuration flexibility | Capable of being configured for simplex, dual, or triple modular redundant (TMR) setups, depending on the system’s reliability requirements |

Product introduction

The GE IS210BPPCH1AD is an I/O Pack Processor Board meticulously engineered for use within General Electric’s Mark VIe Turbine Control System. This system is widely employed in managing and controlling gas, steam, and wind turbine automated drive assemblies, playing a pivotal role in power generation plants across the globe.

The board serves as a crucial link between various input and output devices within the turbine control system. It continuously collects data from sensors, such as temperature sensors, pressure sensors, and speed sensors installed on the turbine. This real – time data is then processed using pre – programmed algorithms. Based on the processed data, the board generates appropriate control signals that are sent to actuators like fuel valves, control valves, and variable speed drives, ensuring the turbine operates at optimal efficiency and safety levels.

It is important to note that the IS210BPPCH1AD is specifically designed for integration into the Mark VIe Turbine Control System and is not compatible with the Mark Vies system. This specialization allows GE to optimize the board’s performance for the unique requirements of the Mark VIe platform.

Core advantages and technical highlights

Reliable I/O processing: The specialized processor on the IS210BPPCH1AD ensures stable and accurate handling of I/O operations. For example, in a gas turbine power plant, it precisely processes the signals from temperature sensors located at critical points in the combustion chamber. Based on these signals, it can accurately adjust the fuel flow to maintain the ideal combustion temperature, which is essential for efficient power generation and preventing damage to the turbine blades.

Flexible configuration options: The board can be configured in simplex, dual, or triple modular redundant (TMR) setups. In a dual – configuration setup, used in medium – critical applications, if one board fails, the other can take over the I/O processing tasks, minimizing downtime. In high – availability power generation scenarios, such as in large power plants where continuous operation is crucial, a TMR configuration can be used. Here, three identical boards operate in parallel, and the system can tolerate the failure of one or even two boards without significant disruption to the turbine control operations.

Robust environmental performance: With its ability to operate in temperatures from – 10°C to + 55°C and resistance to EMI and vibration, the IS210BPPCH1AD can withstand the harsh conditions of industrial power generation facilities. In a wind turbine installation, where the control system is exposed to strong vibrations due to the rotation of the blades and changing wind speeds, and also to electromagnetic interference from the generator and other electrical components, the board continues to function reliably.

Advanced diagnostic capabilities: The onboard diagnostic features, along with LED indicators, make it easy to identify issues. A red LED might indicate a serious fault, such as a communication breakdown with a critical sensor, while a green LED can show normal operation. This simplifies troubleshooting for maintenance technicians. For instance, if a turbine’s performance starts to degrade, the diagnostic system on the IS210BPPCH1AD can quickly point to whether the problem lies in a sensor malfunction, a communication glitch, or an issue with the control algorithm implementation.

Typical application scenarios

Gas turbine power plants: In a gas – fired power plant, the IS210BPPCH1AD is used to control the complex interplay of various components. It monitors the temperature and pressure of the incoming natural gas, the speed of the turbine shaft, and the temperature of the exhaust gases. Based on this data, it adjusts the fuel injection rate, the position of the combustion air control valves, and the speed of the compressor, ensuring efficient combustion and maximum power output while adhering to environmental emission standards.

Steam turbine power plants: In a steam turbine power plant, the board plays a vital role in controlling the steam flow to the turbine. It receives input from sensors that measure the steam pressure, temperature, and flow rate. Using this information, it adjusts the steam control valves to regulate the speed and power output of the turbine. Additionally, it monitors the temperature of the turbine bearings and other critical components and can trigger alarms or take corrective actions if abnormal conditions are detected.

Wind turbine farms: For large – scale wind turbine installations, the IS210BPPCH1AD is used to manage the control system. It receives data from wind speed and direction sensors, pitch angle sensors on the turbine blades, and sensors that monitor the generator’s performance. Based on this data, it adjusts the pitch angle of the blades to optimize power capture from the wind, controls the yaw system to align the turbine with the wind direction, and manages the speed of the generator to ensure stable power output.

Comparison with related models in the series

IS210BPPCH1AD vs. other I/O Pack Processor Boards in the Mark VIe series: Some other boards in the series might have fewer I/O channels, making them suitable for smaller – scale turbine installations or applications with less complex I/O requirements. The IS210BPPCH1AD, on the other hand, offers a higher number of I/O channels and more advanced processing capabilities, making it ideal for large – scale power generation plants with numerous sensors and actuators. Additionally, compared to basic models, it has enhanced diagnostic features that can provide more detailed information about system faults, reducing troubleshooting time.

Compared with similar products from other brands: GE’s IS210BPPCH1AD benefits from GE’s extensive experience in turbine control systems. It is seamlessly integrated with the entire Mark VIe platform, ensuring compatibility and optimized performance. In contrast, some competitor products might require additional hardware or software to interface with the turbine control system fully. GE also provides a comprehensive range of support services, including technical documentation, software updates, and on – site maintenance, which is often more extensive than what some other brands offer.

Installation, commissioning and maintenance instructions

Installation preparation

Select a suitable location within the control system enclosure, ensuring proper ventilation to dissipate heat generated by the board. The location should also be protected from excessive dust, moisture, and physical damage.

Verify that the power supply available meets the board’s requirements of 9 – 16 VDC, with proper grounding and appropriate over – voltage and under – voltage protection devices in place.

Gather the necessary installation tools, such as screwdrivers, anti – static wristbands (to prevent electrostatic discharge damage to the sensitive components on the board), and cable management tools.

Review the detailed installation manual provided by GE, which includes specific mounting dimensions, wiring diagrams, and torque specifications for electrical connections.

Prepare the I/O cables and communication cables, ensuring they are of the correct type and are shielded to minimize EMI interference.

Commissioning process

Mount the IS210BPPCH1AD securely in the designated location within the enclosure, following the manufacturer’s guidelines for proper alignment and fastening.

Connect the power cables, double – checking the polarity to avoid damage to the board. Ensure the connections are tight to prevent electrical arcing.

Wire the I/O channels to the respective sensors and actuators according to the wiring diagram. Verify that analog and digital signals are correctly assigned to the appropriate channels.

Connect the communication cables to other components of the Mark VIe Turbine Control System, such as the main control unit or other I/O modules. Configure the network parameters, such as IP addresses or communication protocol settings, as required.

Power on the board and check the LED indicators. A normal startup sequence should result in the green LED indicating normal operation, while any abnormal conditions should be signaled by the red LED.

Use GE’s dedicated configuration software, such as ToolboxST, to load the appropriate control algorithms, configure the I/O settings (such as input ranges and output types), and set the necessary process parameters (like setpoints for temperature or pressure control).

Test each I/O channel by simulating inputs (e.g., using a signal generator for analog inputs) or activating outputs (e.g., by sending control commands to actuators) to verify correct operation.

Perform a full system test under normal operating conditions, monitoring the turbine’s performance and ensuring that the board is accurately controlling all relevant parameters.

Document all configuration settings, test results, and wiring diagrams for future reference and maintenance.

Maintenance suggestions

Conduct regular visual inspections of the board to check for any loose connections, signs of overheating (such as discolored components or a burnt smell), or dust accumulation. Loose connections can cause intermittent failures, while dust can impede heat dissipation.

Clean the board’s surface and ventilation slots periodically using compressed air. This helps prevent dust buildup, which can lead to overheating and component failure.

Monitor the diagnostic indicators and any alarms generated by the control system. Early detection of issues, such as a sensor that is starting to drift or a communication link that is becoming unstable, can prevent major failures.

Calibrate the analog input channels periodically using standard calibration equipment. This ensures that the data received from sensors is accurate, which is crucial for proper turbine control.

Back up the configuration data and control algorithms regularly to a secure location, such as an external hard drive or a network – attached storage device. In case of board failure or software corruption, this data can be used to quickly restore the system to its previous working state.

Update the board’s firmware to the latest version using GE’s approved software tools. Firmware updates often contain bug fixes, performance improvements, and enhanced security features.

In case of faults, refer to the detailed troubleshooting guide provided by GE. This guide will help isolate issues, whether they are related to power, connections, or software configuration. Replace faulty components with genuine GE spare parts to ensure compatibility and reliability.

Service and guarantee commitment

GE offers a standard warranty for the IS210BPPCH1AD, typically covering manufacturing defects for 12 – 24 months from the date of purchase. Their global technical support team is available 24/7 via phone, email, or online portals. This team can assist with installation queries, troubleshooting complex issues, and providing guidance on configuration.

Customers can access a wealth of technical documentation, software updates, and training materials through GE’s online resources. For more complex problems, GE can dispatch certified engineers for on – site support to ensure timely resolution. Extended warranty options and preventive maintenance services are available. These services can include periodic inspections by GE technicians, proactive firmware updates, and performance validation tests, all aimed at enhancing the long – term reliability of the IS210BPPCH1AD in power generation applications.

Training programs, both online and in – person, are offered to help operators and technicians master the board’s configuration, operation, and maintenance. This training ensures that the board is used to its full potential, minimizing downtime and maximizing the efficiency of the turbine control systems in which it is installed.