Description

Key Technical Specifications

-

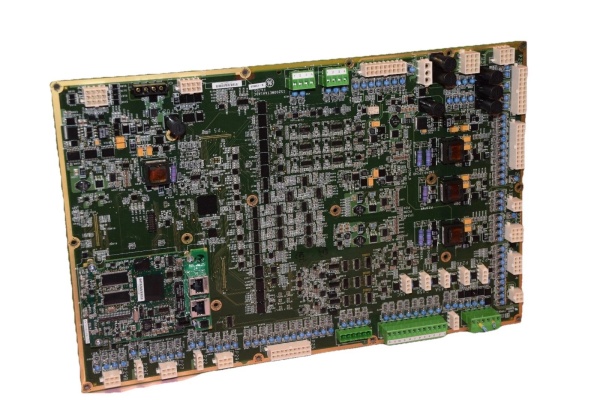

Model Number: IS200WETAH1ADC

-

Manufacturer: General Electric

-

Analog Inputs: 16 differential, 12-bit, ±10 V or 0-20 mA jumper-select, 1 kHz sample rate

-

Relay Outputs: 4 Form-C, 250 VAC / 30 VDC, 2 A resistive

-

Communication: RS-485 Modbus-RTU, 19.2 k fixed, isolated

-

Power Supply: 15 VDC ±5 %, < 2 W consumption

-

Isolation: 1500 Vrms field-to-logic, 500 V channel-to-channel

-

Operating Temperature: –40 °C to +70 °C (conformal-coated)

-

Dimensions / Weight: 101 × 101 × 31 mm, 0.23 kg

IS200WETAH1ADC

Field Application & Problem Solved

Inside a 2 MW nacelle the Mark VI controller needs clean, fast data—blade angle, generator torque, wind speed, and grid volts—all in one bundle. The IS200WETAH1ADC lives in the top-box, samples sixteen sensors at 1 kHz, and ships the data over Modbus-RTU so the torque loop can trim inside 10 ms. When the card fails you lose torque feedback, the turbine folds to “emergency feather,” and you’re down until the next weather window; swap the module, snap the four relay plugs back in, and the unit returns to rated power without re-downloading a single parameter. Found in every GE 1.5–3 MW class from Iowa cornfields to North-Sea jack-ups. Value is speed and density: sixteen channels, four relays, and Modbus in one 100 mm square card—no extra I/O rack required.

Inside a 2 MW nacelle the Mark VI controller needs clean, fast data—blade angle, generator torque, wind speed, and grid volts—all in one bundle. The IS200WETAH1ADC lives in the top-box, samples sixteen sensors at 1 kHz, and ships the data over Modbus-RTU so the torque loop can trim inside 10 ms. When the card fails you lose torque feedback, the turbine folds to “emergency feather,” and you’re down until the next weather window; swap the module, snap the four relay plugs back in, and the unit returns to rated power without re-downloading a single parameter. Found in every GE 1.5–3 MW class from Iowa cornfields to North-Sea jack-ups. Value is speed and density: sixteen channels, four relays, and Modbus in one 100 mm square card—no extra I/O rack required.

Installation & Maintenance Pitfalls (Expert Tips)

15 V supply sag—card resets, torque loop folds

The module wants 15 V ±5 %. If the top-box DC-DC drifts to 13.8 V the A/D reference collapses and torque hunts ±5 %. Meter 15 V at the green two-pin plug before you blame the sensors—five-minute supply swap beats a crane call.

The module wants 15 V ±5 %. If the top-box DC-DC drifts to 13.8 V the A/D reference collapses and torque hunts ±5 %. Meter 15 V at the green two-pin plug before you blame the sensors—five-minute supply swap beats a crane call.

Modbus address clash—wind-speed channel reads zero

Default address is 247. If a tech duplicates it on the same RS-485 spur the master sees garbage and the torque loop drops to failsafe. Always scan the bus with Toolbox-ST before you button up—30 s of housekeeping saves a 2 hr climb.

Default address is 247. If a tech duplicates it on the same RS-485 spur the master sees garbage and the torque loop drops to failsafe. Always scan the bus with Toolbox-ST before you button up—30 s of housekeeping saves a 2 hr climb.

Relay contact weld—brake resistor stays on, grid trips

The four relays are only rated 2 A. If the brake-resistor contactor coil draws > 2 A inductive the contacts weld and the resistor stays in circuit, dragging the grid PF down. Add an interposing relay or check the coil spec—otherwise you’ll be explaining to the ISO why you dragged the grid.

The four relays are only rated 2 A. If the brake-resistor contactor coil draws > 2 A inductive the contacts weld and the resistor stays in circuit, dragging the grid PF down. Add an interposing relay or check the coil spec—otherwise you’ll be explaining to the ISO why you dragged the grid.

Conformal coat cracked—salt fog bridges the reference

The board is coated, but the 20-pin edge is masked. If the coat cracks, salt bridges the 2.5 V reference and you see 5 % offset on every channel. Scrape the salt, hit the edge with 2100-FTG, and re-coat—problem gone for another decade.

The board is coated, but the 20-pin edge is masked. If the coat cracks, salt bridges the 2.5 V reference and you see 5 % offset on every channel. Scrape the salt, hit the edge with 2100-FTG, and re-coat—problem gone for another decade.

IS200WETAH1ADC

Technical Deep Dive & Overview

IS200WETAH1ADC is a micro-size analog front-end frozen in 2000 silicon. A 12-bit ADC samples sixteen channels at 1 kHz; an STM32 MCU packs the data into Modbus-RTU frames; four relay drivers give hard-wired brake-resistor or pitch-motor interlocks. Because the card carries both analog and serial traffic you can swap it hot and the turbine never knows—just kill the 15 V supply first or you’ll arc-weld the two-pin plug. Treat the Modbus pair like instrumentation cable and the board will keep the torque loop locked for another thirty years .

IS200WETAH1ADC is a micro-size analog front-end frozen in 2000 silicon. A 12-bit ADC samples sixteen channels at 1 kHz; an STM32 MCU packs the data into Modbus-RTU frames; four relay drivers give hard-wired brake-resistor or pitch-motor interlocks. Because the card carries both analog and serial traffic you can swap it hot and the turbine never knows—just kill the 15 V supply first or you’ll arc-weld the two-pin plug. Treat the Modbus pair like instrumentation cable and the board will keep the torque loop locked for another thirty years .