Description

Key Technical Specifications

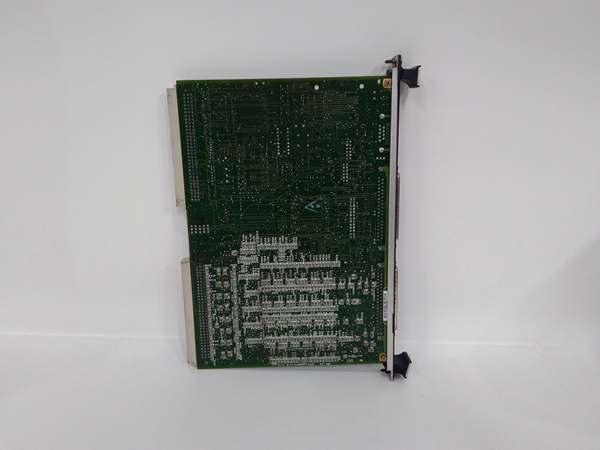

- Model Number: IS200VCRCH1Bworldofcontrols

- Manufacturer: General Electric (GE)rms-dcs

- System Series: Mark VI gas/steam turbine control (VME-based)rms-dcs

- Functional Type: Contact Input / Relay Output discrete I/O processor boardaxcontroler

- Discrete Inputs: 48 dry contact inputs via one or two TBCI terminal boardsworldofcontrols

- Relay Outputs: 24 outputs (12 solenoid-type, 12 dry contact via TRLY) depending on terminal board configurationtopbrandsplc

- Terminal Board Interfaces: Dual J3/J4 style connectors to TBCI (inputs) and TRLY (relay outputs)axcontroler

- Scan / SOE Resolution: Contact inputs sampled at control frame rate, with SOE recording at 1 ms resolution; can detect contact chatter and pulses down to roughly 6 msrms-dcs

- Isolation: Optical isolation on each input; floating 125 Vdc (approx. 100–145 Vdc) input supply typical for dry contactsworldofcontrols

- Mounting Format: Double-width VME I/O board (VCCC style) with on-board daughterboard, fits Mark VI I/O rack slotsaxcontroler

- Status Indicators: Front face RUN (green), FAIL (red), and STATUS (amber) LEDs for health and diagnostics (same behavior as VCRC/IS200VCRCH1BBB variants)topbrandsplc

- Application Modes: Simplex and TMR architectures; inputs distributed to multiple racks in TMR via JR1/JS1/JT1 links and voted in VCMItopbrandsplc

GE IS200VCRCH1B

Field Application & Problem Solved

Out in a turbine control room, the real headache is not the CPU—it is the mess of field contacts that all have to be monitored, time-stamped, and acted on without missing a beat. You have trips, permissives, interlocks, and dozens of solenoids and relays scattered across the skid. The board in question solves the classic problem of how to bring a large number of dry contacts and relay loads into the Mark VI control system in a way that is deterministic, noise-tolerant, and easy to troubleshoot under pressure.rms-dcs

You will typically see this board sitting in a Mark VI VME I/O rack, cabled to TBCI terminal boards for contact inputs and TRLY boards for relay/solenoid outputs. It lives in gas turbine and steam turbine applications—combustion turbines, HRSGs, and balance-of-plant panels—handling things like valve limit switches, pressure or level switch contacts, breaker status, hydraulic skid permissives, as well as solenoid-activated trip valves and igniter circuits. In TMR configurations, three of these boards live in three separate racks, each fed from its own contact input distribution, and then voted through the VCMI, so a single bad card does not take down your protection logic.topbrandsplc

The core value is twofold. First, it consolidates 48 inputs and 24 outputs into a single intelligent node that handles optical isolation, high-speed sampling, and sequence-of-events stamping at the board level. That means you can reconstruct exactly what opened or closed leading up to a trip, down to the millisecond, instead of arguing about which relay “really” dropped first. Second, it takes the burden of raw contact conditioning and relay drive away from ad hoc field wiring. Power for dry contacts, suppression for solenoids, and proper isolation are all built into the terminal-board-plus-I/O-board combination, which greatly reduces nuisance trips and ghost signals that come from poorly designed panel wiring.worldofcontrols

Installation & Maintenance Pitfalls (Expert Tips)

Do Not Treat Inputs Like Wet Contacts

The inputs are designed around dry contacts powered from a controlled floating 125 Vdc supply via the TBCI board. Treating them like generic “any voltage is fine” inputs is how people cook opto-isolators or end up with phantom states. Always verify that the field side is truly a potential-free contact closing back to the appropriate return, and that any external indication lamps or devices are powered from a separate source, not through the contact input loop.axcontroler

Respect the Terminal Board Pairing (TBCI / TRLY)

The board itself is just the brains. All the real-world wiring lands on the TBCI (inputs) and TRLY (outputs). Mixing terminal board types, reusing cables from another card type, or cross-landing contacts between “rack R” and “rack S” in a TMR system is a classic commissioning error that leads to impossible-to-explain trip logic. Always confirm that the cable from J3/J4 actually goes to the matching TBCI/TRLY part numbers, and that channel numbering on the drawings matches the physical terminal strips.rms-dcs

TMR Voting Only Works if Channels Match

On TMR units, three racks are supposed to see the same field contact set so the VCMI can vote correctly. If one rack sees normally-closed, another sees normally-open, or one leg is left unwired “for later,” the system will constantly flag miscompare alarms and may block starts or trip unexpectedly. Before blaming the card, check that JR1/JS1/JT1 feeds and field terminations are consistent across R/S/T racks.topbrandsplc

SOE Timing is Only as Good as Your Contact Quality

The hardware can record events down to roughly 1 ms with contact chatter detection, but if you run long, unshielded cables in noisy cable trays or use cheap relays that bounce excessively, your SOE logs will be full of noise. That shows up as multiple open/close entries for one mechanical event. Use good-quality relays, keep signal wiring away from high-current runs, and terminate shields properly at one end to give the board a clean signal to work with.worldofcontrols

Don’t Ignore the Front-Panel LEDs

RUN, FAIL, and STATUS on the front edge are not decoration. A flashing green RUN with no red FAIL means the board is alive and talking. A steady red FAIL or orange STATUS lit during operation usually means configuration mismatch, internal diagnostics issues, or bad communications with the VCMI. When the plant is down and everyone is panicking, those three LEDs are the fastest first check before you start swapping hardware.axcontroler

GE IS200VCRCH1B

Technical Deep Dive & Overview

Functionally, this board sits between the “analog world” of mechanical contacts and relays and the digital world of the Mark VI controller. On the input side, each field contact lands on the TBCI terminal board, where a controlled floating 125 Vdc source feeds the dry contact circuits. When a contact closes, the resulting voltage is presented through conditioning and optical isolation, then forwarded across the cables into the I/O board. The board samples those opto-isolated signals at the main control frame rate for real-time logic and at a higher-resolution 1 ms rate for sequence-of-events recording. That dual-scan behavior lets the controller use debounced logic while still preserving a fine-grained event history.rms-dcs

On the output side, the board sends relay drive commands to the TRLY terminal board, where plug-in magnetic relays and associated fusing/suppression handle the field solenoid or dry contact loads. Some outputs are jumper-selectable between driving powered solenoids and providing clean Form-C contacts, with standard field supplies like 125 Vdc or 115 Vac wired through fused, suppressor-protected circuits. The I/O board reports feedback from these outputs back into the controller, closing the loop so the logic can validate that a commanded output actually changed state. In TMR systems, three identical boards in three racks each process their own set of inputs, then pass results back through the VCMI for voting, so a single failure or noisy leg does not compromise trip integrity. Overall, the board is the discrete workhorse that quietly keeps the turbine’s interlocks, permissives, and trips honest and time-aligned.topbrandsplc