Description

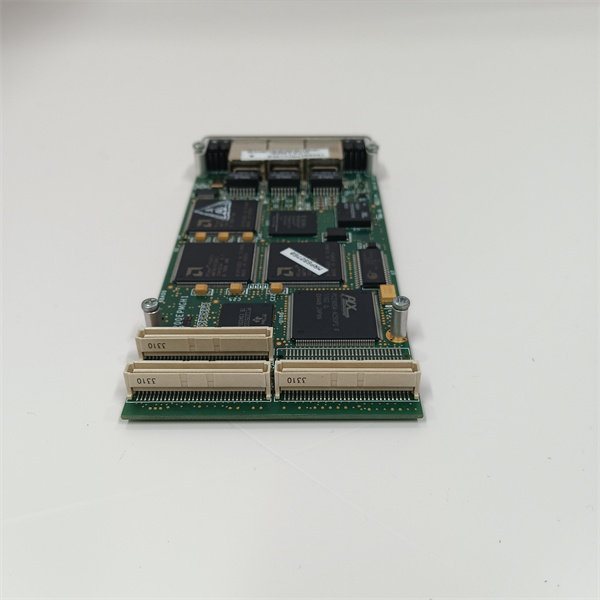

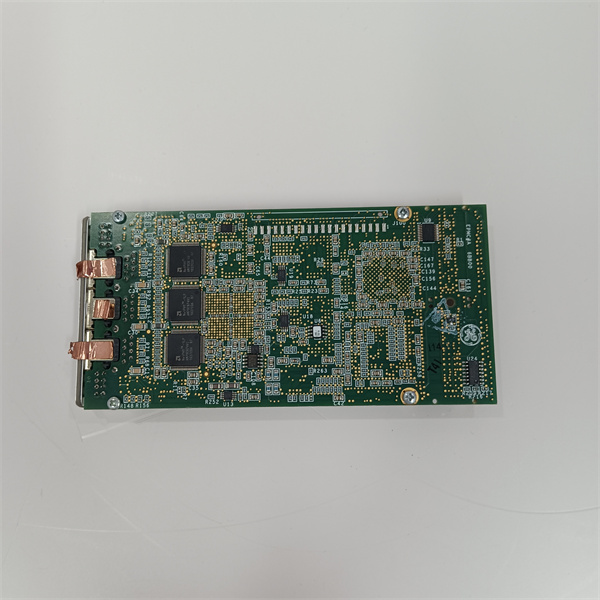

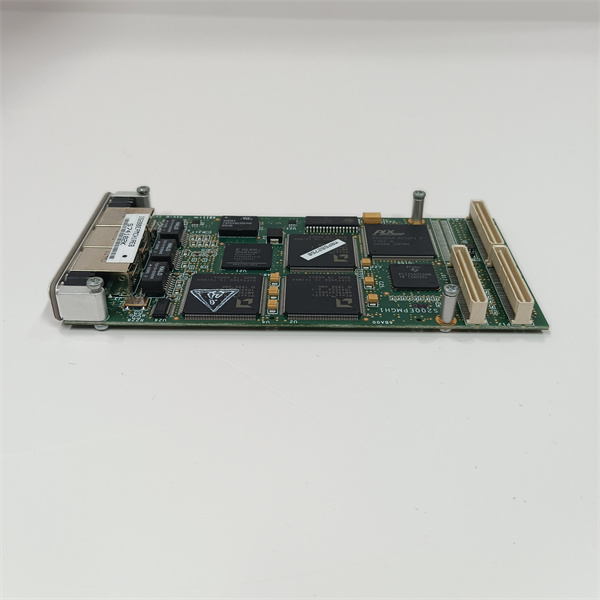

GE IS200EPMCH1

Detailed parameter table

| Parameter name | Parameter value |

| Product model | IS200EPMCH1 |

| Manufacturer | GE (General Electric) |

| Product category | Power supply module for Mark VIe turbine control systems |

| Input voltage range | 85-264 VAC, 47-63 Hz |

| Output voltage | 24 VDC ±0.5% |

| Output current | 10 A maximum |

| Efficiency | ≥90% at full load |

| Overload protection | 110-150% of rated current (hiccup mode) |

| Short circuit protection | Latched, auto-recovery after fault removal |

| Ripple and noise | ≤50 mV peak-to-peak |

| Operating temperature | 0°C to +55°C |

| Storage temperature | -40°C to +85°C |

| Humidity tolerance | 5-95% RH, non-condensing |

| MTBF (Mean Time Between Failures) | ≥100,000 hours at 25°C |

| Physical dimensions | 120 mm x 80 mm x 40 mm (length x width x height) |

| Mounting type | Backplane-mounted in Mark VIe chassis |

| Certification | UL 60950, IEC 60950, CE marked |

GE IS200EPMCH1

Product introduction

The GE IS200EPMCH1 is a high-reliability power supply module specifically engineered for GE’s Mark VIe turbine control systems, a premier platform in power generation and industrial turbomachinery control. As a critical power source within the control architecture, it converts AC input power into stable 24 VDC output, delivering consistent power to key components such as processor modules, I/O cards, and communication interfaces.

This module is designed to meet the rigorous demands of turbine control environments, where uninterrupted power is essential for safe and efficient operation. Its robust design ensures reliable performance even during voltage fluctuations or transient conditions common in industrial settings. By providing clean, regulated power, the IS200EPMCH1 safeguards sensitive electronics in the Mark VIe system, preventing data corruption or system shutdowns that could disrupt turbine operation. Whether deployed in gas, steam, or combined-cycle plants, it serves as a foundational component for maintaining control system integrity.

Core advantages and technical highlights

Wide input range: The IS200EPMCH1 accepts 85-264 VAC input, making it compatible with global power grids. This flexibility allows seamless integration in regions with varying voltage standards, from 110 VAC in North America to 220 VAC in Europe and Asia, eliminating the need for additional voltage transformers.

Stable output regulation: With ±0.5% voltage regulation, the module delivers precise 24 VDC power even under varying load conditions. This stability is critical for sensitive components like analog I/O modules in the Mark VIe system, where voltage fluctuations could introduce measurement errors in turbine sensors (e.g., pressure transducers or thermocouples).

Comprehensive protection features: Equipped with overload, short circuit, and overvoltage protection, the IS200EPMCH1 prevents damage to both itself and connected equipment. In the event of a short circuit in a downstream module, its latched protection mode shuts down output until the fault is cleared, avoiding cascading failures in the control system.

High efficiency and low noise: Operating at ≥90% efficiency, the module minimizes power loss and heat generation, reducing cooling requirements in control cabinets. Its low ripple (≤50 mV) ensures clean power delivery, preventing electromagnetic interference (EMI) that could disrupt communication between Mark VIe components.

Hot-swap capability: Designed for backplane mounting in Mark VIe chassis, the IS200EPMCH1 supports hot-swap replacement. This allows maintenance personnel to replace a faulty unit without powering down the entire control system, minimizing downtime in critical turbine applications.

Typical application scenarios

In gas turbine power plants, the IS200EPMCH1 serves as the primary power source for the Mark VIe control system’s core components. It supplies power to processor modules (like the IS215UCCCM04A), I/O cards monitoring turbine speed and temperature, and communication interfaces linking the control system to operator workstations. During turbine startups—when power grids often experience fluctuations—its wide input range ensures stable power delivery, preventing premature shutdowns.

In combined-cycle facilities, the module supports redundant control configurations. Paired with a second IS200EPMCH1, it creates a 2N power supply architecture where each module handles 50% of the load. If one unit fails, the other seamlessly assumes full load, ensuring uninterrupted operation of the control system that coordinates gas and steam turbine interactions.

In industrial cogeneration plants, the IS200EPMCH1 powers control components managing turbine-driven generators that supply both electricity and process steam. Its robust protection features shield the control system from power anomalies caused by sudden changes in plant load (e.g., when a manufacturing line ramps up steam demand), maintaining stable turbine operation.

GE IS200EPMCH1

Related model recommendations

GE IS200EPMCH2: A higher-current variant (15 A) of the IS200EPMCH1, suitable for Mark VIe systems with expanded I/O configurations or additional peripherals.

GE IS200PPSCH1: A redundant power supply controller that pairs with two IS200EPMCH1 modules, enabling automatic failover and load balancing in critical applications.

GE IS215UCCCM04A: A processor module in the Mark VIe system, directly powered by the IS200EPMCH1, relying on its stable output for precise control algorithm execution.

GE IS220PTURH1A: A turbine trip pack module that receives 24 VDC from the IS200EPMCH1, ensuring reliable operation of safety-critical overspeed protection functions.

GE IS200IOVHM01A: An analog I/O module that depends on the IS200EPMCH1 for clean power to maintain accuracy in measuring turbine pressure and temperature signals.

Installation, commissioning and maintenance instructions

Installation preparation: Ensure the Mark VIe chassis is powered off before installing the IS200EPMCH1. Verify that the backplane connector is clean and free of debris to ensure proper electrical contact. Check the AC input supply voltage (85-264 VAC) with a multimeter to confirm it matches the module’s specifications. Use anti-static gloves when handling the unit to prevent electrostatic damage to internal components.

Commissioning steps: Insert the IS200EPMCH1 into the designated backplane slot and secure it with the locking latch. Power on the AC supply and verify the module’s front-panel LED illuminates green (indicating normal operation). Use a multimeter to measure the 24 VDC output at the backplane terminals, confirming it reads between 23.8 and 24.2 VDC. Test overload protection by connecting a variable load and gradually increasing current to 110% of rated capacity—ensure the module enters hiccup mode and recovers once load is reduced.

Maintenance suggestions: Perform quarterly visual inspections to check for loose connections or dust accumulation; use compressed air to clean vents if needed. Monitor the module’s temperature during operation—values exceeding 55°C may indicate airflow issues. Track output voltage monthly using the Mark VIe HMI; fluctuations beyond ±0.5% warrant further inspection. In case of failure (indicated by a red LED), replace the IS200EPMCH1 with a genuine GE unit to maintain system compatibility. Store spare modules in a dry environment within the -40°C to +85°C range.

Service and guarantee commitment

GE provides a 2-year warranty for the IS200EPMCH1, covering manufacturing defects and performance failures under normal operating conditions. Their global technical support team offers 24/7 assistance, including remote diagnostics to identify power supply issues via Mark VIe system logs. For critical installations, GE engineers can perform on-site power quality assessments to ensure the module operates within specified input parameters.

Customers gain access to GE’s online portal with technical manuals, installation guides, and firmware updates for the IS200EPMCH1. Extended warranty options (up to 5 years) include annual preventive maintenance checks, where certified technicians verify output stability and protection functions. GE’s commitment to reliability ensures the IS200EPMCH1 delivers consistent power to Mark VIe systems, minimizing unplanned downtime in turbine operations.