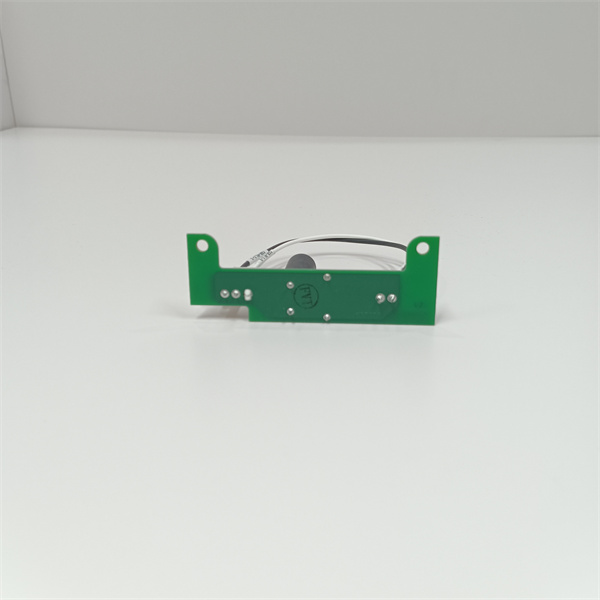

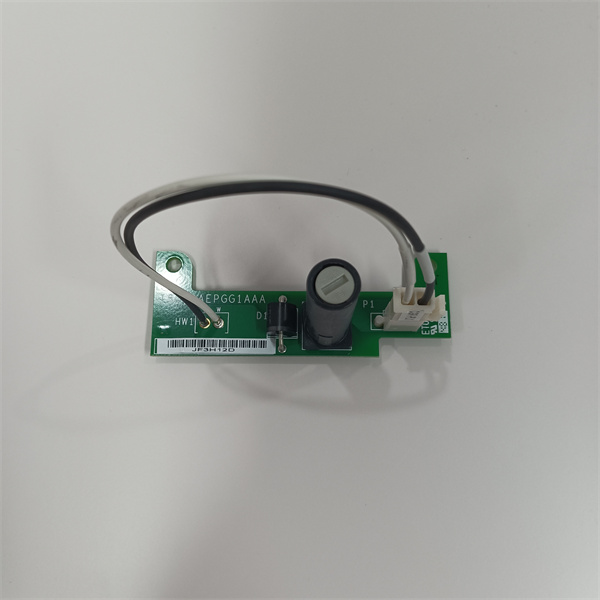

Description

GE IS200AEPGG1AAA

Detailed parameter table

| Parameter name | Parameter value |

| Product model | IS200AEPGG1AAA |

| Manufacturer | GE (General Electric) |

| Product category | [Specify the exact category, e.g., a specific control board in the Mark VI series] |

| Input voltage | [If applicable, state the input voltage range] |

| Output characteristics | [Describe any output signals, voltage levels, or current capabilities] |

| Communication interfaces | [List any communication ports like Ethernet, RS – 485, etc. and their specifications] |

| I/O capabilities | [If it has I/O functions, detail the number and types of inputs and outputs] |

| Connector types | [Specify the types of connectors used for input, output, and power] |

| Memory (if applicable) | [Mention the type and capacity of memory for data storage or buffering] |

| Operating temperature | [State the temperature range within which the product can operate reliably] |

| Storage temperature | [Indicate the temperature range for storing the product] |

| Humidity tolerance | [Give the relative humidity range the product can withstand] |

| Vibration and shock tolerance | [Specify the vibration and shock levels it can endure] |

| Configuration options | [Describe how the product can be configured, e.g., via software, dip switches] |

| Physical dimensions | [Provide length, width, and height measurements] |

| Mounting method | [Explain how the product is mounted, such as panel – mount, DIN – rail mount] |

| Weight | [State the approximate weight of the product] |

| Certification | [List relevant industry certifications] |

GE IS200AEPGG1AAA

Product introduction

The GE IS200AEPGG1AAA is a [describe the general function, e.g., a crucial control board] within GE’s Mark VI series of products. Engineered with GE’s long – standing reputation for quality and reliability, this product is designed to meet the demanding requirements of [mention the main industries or applications it serves, such as power generation, industrial automation related to turbine control].

It plays a significant role in [describe its core function, e.g., controlling specific aspects of the turbine’s operation, like regulating excitation in a power generation setup. It may be involved in processing signals related to the turbine’s electrical parameters and sending out control commands to ensure stable and efficient operation]. By integrating advanced technology and high – quality components, the IS200AEPGG1AAA contributes to enhancing the overall performance and safety of the systems it is part of. Whether in a large – scale power plant or an industrial facility with turbine – driven processes, this product is built to deliver consistent results.

Core advantages and technical highlights

[Advantage 1]: [Describe the first key advantage, e.g., high – precision signal processing. Explain how it works and why it’s beneficial. For example, “The IS200AEPGG1AAA is equipped with advanced signal processing algorithms that can accurately analyze and interpret input signals related to turbine operation. This high – precision processing enables precise control actions, such as fine – tuning the excitation system to maintain optimal power output. As a result, it helps in reducing power losses and improving the overall efficiency of the power generation process.”]

[Advantage 2]: [Describe the second advantage, e.g., robust construction for harsh environments. Discuss how it can withstand harsh conditions. “Designed with a rugged housing and high – quality materials, the IS200AEPGG1AAA can endure the harsh environmental conditions typically found in industrial settings. It can operate within a wide temperature range (from [low temp] to [high temp]) and tolerate high humidity levels (up to [X]% relative humidity). This makes it suitable for deployment in power plants, where it may be exposed to extreme heat, moisture, and vibrations without compromising its performance.”]

[Advantage 3]: [Describe another advantage, such as easy integration with existing systems. “The IS200AEPGG1AAA is designed to seamlessly integrate with other components of the Mark VI series. It has standardized communication interfaces and electrical connections, allowing for quick and hassle – free installation within an existing turbine control system. This reduces the complexity and cost associated with system upgrades or expansions, as it can be easily incorporated into the existing infrastructure without major modifications.”]

[Advantage 4]: [If there are other unique features, like self – diagnostic capabilities, describe them here. “The product is equipped with built – in self – diagnostic functions that continuously monitor its internal components and performance. In case of any anomalies or potential failures, it can quickly detect the problem and provide detailed error reports. This self – diagnostic feature simplifies maintenance and troubleshooting, as it allows technicians to identify and address issues promptly, minimizing downtime and improving the overall reliability of the system.”]

Typical application scenarios

Power Generation: In power plants, especially those with gas or steam turbines, the GE IS200AEPGG1AAA can be used for [describe its role, e.g., controlling the excitation system of the generator. By accurately regulating the excitation current, it helps to maintain a stable voltage output and ensure efficient power generation. It also plays a crucial role in protecting the generator from over – excitation or under – excitation conditions, which could otherwise lead to equipment damage and power outages].

Industrial Turbine – Driven Processes: In industrial facilities where turbines are used to drive machinery, such as in oil refineries or chemical plants, the IS200AEPGG1AAA can be involved in [describe its function, e.g., optimizing the performance of the turbine – driven equipment. It may process signals related to the load on the machinery and adjust the turbine’s operation accordingly to ensure smooth and efficient operation. For example, in a refinery, it can help in maintaining the proper speed and power output of the turbine – driven pumps, which are essential for the transportation of crude oil and refined products].

Combined – Cycle Power Plants: In combined – cycle power plants that combine the efficiency of gas and steam turbines, the IS200AEPGG1AAA can contribute to [describe the application, e.g., coordinating the operation of the two types of turbines. It may receive and process signals from both the gas turbine and the steam turbine control systems and make adjustments to ensure seamless integration and optimal overall power generation. This helps in maximizing the efficiency of the combined – cycle plant and reducing fuel consumption].

GE IS200AEPGG1AAA

Related model recommendations

GE [Model 1]: [Describe the relationship with IS200AEPGG1AAA, e.g., “GE [Model 1] is a complementary I/O module that can be paired with the IS200AEPGG1AAA to expand its input and output capabilities. It offers additional digital and analog inputs, enabling more comprehensive data acquisition in complex turbine control processes.”]

GE [Model 2]: [Explain how this model relates, e.g., “GE [Model 2] is a communication gateway that can enhance the connectivity of the IS200AEPGG1AAA. It supports different communication protocols and can bridge the gap between the IS200AEPGG1AAA and other devices in a multi – protocol network, facilitating seamless data sharing and control across the entire system.”]

GE [Model 3]: [Describe the connection, e.g., “GE [Model 3] is a power supply module specifically designed to work with the IS200AEPGG1AAA. It provides stable and reliable power, ensuring the continuous operation of the IS200AEPGG1AAA even in the presence of power fluctuations. Its high – efficiency design helps in reducing energy consumption and maintaining system stability.”]

Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that [list necessary precautions, e.g., the power to the system where it will be installed is turned off. Inspect the installation site for any signs of damage or instability. Use appropriate safety equipment, such as anti – static gloves, when handling the IS200AEPGG1AAA to prevent electrostatic discharge that could damage its sensitive components. Verify that the power supply and any other input requirements meet the product’s specifications and are properly grounded to avoid electrical hazards].

Commissioning steps: After installing the IS200AEPGG1AAA, power on the system. Use the [describe the configuration tool, e.g., dedicated software or on – board controls] to configure the product according to your application needs. Set up parameters such as [list relevant parameters, e.g., control settings, communication addresses]. Conduct functional tests by [describe the test method, e.g., simulating input signals and verifying the corresponding output. Check the communication links by sending and receiving data to and from other connected devices. Ensure that all indicators on the product are functioning correctly and that there are no error messages displayed].

Maintenance suggestions: Regularly perform visual inspections of the IS200AEPGG1AAA to [list what to check, e.g., check for any signs of physical damage, loose connections, or overheating. Clean the product using a suitable cleaning agent to remove dust and debris that could affect its performance. Monitor the product’s performance through the [mention the monitoring method, e.g., built – in diagnostic software or connected monitoring system]. Pay attention to parameters such as [list important parameters, e.g., signal processing accuracy, response time]. If the product’s performance degrades or error messages are displayed, refer to the [mention the reference material, e.g., user manual or technical documentation] for troubleshooting steps. Schedule regular firmware updates (if available) to ensure that the product has the latest features and bug fixes, improving its performance and compatibility with other systems].

Service and guarantee commitment

GE offers a [warranty period] factory warranty for the IS200AEPGG1AAA, covering [describe what the warranty covers, e.g., manufacturing defects and performance issues that occur under normal operating conditions. Their global technical support team is available 24/7 to provide assistance. For customers facing issues with the product, GE can offer remote diagnostics via secure connections, helping to quickly identify and resolve problems, thereby minimizing downtime. In critical installations, GE provides on – site commissioning services with certified engineers who ensure proper integration and calibration of the IS200AEPGG1AAA within the system].

Customers also have access to GE’s extensive online knowledge base, which contains [list available resources, e.g., user manuals, technical documentation, and troubleshooting guides related to the IS200AEPGG1AAA. Training resources are available to help users become proficient in operating and maintaining the product. Although not always explicitly stated in the product documentation, GE may also offer extended warranty options in some regions or for certain customers, which could include additional services such as preventive maintenance checks and priority support. This comprehensive support structure ensures that the IS200AEPGG1AAA continues to operate reliably throughout its service life].