Description

Parameter table

| Parameter name | Parameter value |

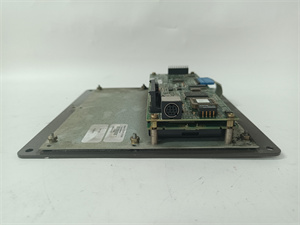

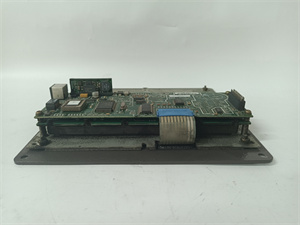

| Product model | IC752SPL013-BA EX2100 |

| Manufacturer | General Electric (GE) |

| Product category | Programmable Logic Controller (PLC) Module |

| Dimensions (approx.) | Compact design suitable for panel mounting, specific dimensions available in product manuals |

| Weight | Lightweight for easy installation and handling |

| Processor | High-performance processor for efficient program execution and data processing |

| Memory | Sufficient memory for program storage and data logging, with expandable options |

| I/O capability | Supports a range of digital and analog I/O modules for versatile connectivity |

| Communication ports | Multiple communication ports including Ethernet, RS-232, and RS-485 for seamless integration |

| Programming software | Compatible with GE’s Proficy Machine Edition software for easy programming and configuration |

| Operating temperature range | -20°C to +60°C, ensuring reliable operation in harsh industrial environments |

| Power supply | 24 V DC, compatible with standard industrial power systems |

| Certifications | Complies with international standards such as IEC 61131-2, ensuring quality and safety |

| Expansion capability | Supports expansion with additional I/O modules and communication interfaces |

GE IC752SPL013-BA EX2100

Product introduction

The GE IC752SPL013-BA EX2100 is a high-performance programmable logic controller (PLC) module, a key component in industrial automation systems. As part of GE’s EX2100 series, it is designed to provide reliable and flexible control for a wide range of industrial processes.

This PLC module acts as the central processing unit for industrial control systems, executing pre-programmed logic to monitor and control various devices and processes. It receives input signals from sensors and other devices, processes this information based on the programmed logic, and then sends output signals to actuators, motors, and other equipment to regulate the industrial process.

With its advanced features and robust design, the IC752SPL013-BA EX2100 is suitable for applications in industries such as manufacturing, packaging, material handling, and water treatment. It enables precise control, real-time monitoring, and efficient operation of industrial processes, helping to improve productivity, reduce downtime, and ensure product quality.

Core advantages and technical highlights

Powerful processing performance: Equipped with a high-performance processor, the IC752SPL013-BA EX2100 can quickly execute complex control programs. This ensures fast response times to input signals, allowing for real-time control of industrial processes. For example, in a high-speed packaging line, the PLC can rapidly process signals from sensors detecting product position and adjust the operation of conveyor belts and packaging machinery to ensure accurate and efficient packaging.

Versatile I/O capability: The module supports a wide range of digital and analog I/O modules, providing flexible connectivity with various sensors, actuators, and other devices. This versatility allows it to adapt to different industrial applications with varying I/O requirements. Whether it’s monitoring temperature and pressure with analog sensors or controlling on/off valves with digital outputs, the IC752SPL013-BA EX2100 can handle it all, making it a versatile solution for diverse industrial needs.

Multiple communication options: With multiple communication ports including Ethernet, RS-232, and RS-485, the PLC module can easily integrate with other devices and systems in the industrial network. It can communicate with human-machine interfaces (HMIs), supervisory control and data acquisition (SCADA) systems, and other PLCs, enabling data exchange and remote monitoring and control. This seamless communication is essential for creating a connected and intelligent industrial automation system, allowing operators to monitor and manage processes from a central location.

Rugged design for harsh environments: The IC752SPL013-BA EX2100 is built to withstand harsh industrial environments. Its operating temperature range of -20°C to +60°C ensures reliable operation in extreme temperature conditions. It is also resistant to vibration, shock, and electromagnetic interference, making it suitable for installation in factories, warehouses, and other industrial settings where environmental conditions can be challenging.

Easy programming and configuration: Compatible with GE’s Proficy Machine Edition software, the PLC module offers user-friendly programming and configuration. The software provides a graphical programming environment with standard programming languages such as ladder logic, function block diagram, and structured text, making it easy for engineers and technicians to develop and modify control programs. This reduces the time and effort required for system setup and maintenance, improving overall efficiency.

Typical application scenarios

Manufacturing industry: In manufacturing plants, the IC752SPL013-BA EX2100 can be used to control production lines. It can monitor the status of machines, sensors, and conveyors, and execute control logic to ensure smooth operation. For example, in an automotive assembly line, the PLC can control the movement of robotic arms, the feeding of parts, and the testing of finished products. It can detect faults in the production process and trigger alarms or shut down specific equipment to prevent damage, ensuring high-quality production and reducing waste.

Packaging industry: In packaging facilities, the PLC module is essential for controlling packaging machinery. It can regulate the speed of packaging lines, adjust the amount of packaging material used, and ensure that products are properly sealed and labeled. For instance, in a food packaging plant, the PLC can monitor the flow of food products and control the packaging machines to wrap them in the correct amount of film, ensuring freshness and preventing spoilage. It can also coordinate with vision systems to inspect packaged products for defects, ensuring only high-quality products are shipped.

Material handling industry: In warehouses and distribution centers, the IC752SPL013-BA EX2100 can control material handling equipment such as conveyors, cranes, and automated guided vehicles (AGVs). It can manage the movement of goods, track inventory, and optimize the flow of materials. For example, the PLC can receive signals from barcode scanners to identify products and direct them to the correct storage location via conveyors. It can also coordinate the operation of AGVs to transport goods between different areas of the warehouse, improving efficiency and reducing manual labor.

Water and wastewater treatment: In water and wastewater treatment plants, the PLC module can control various processes such as filtration, pumping, and chemical dosing. It can monitor water quality parameters such as pH, turbidity, and dissolved oxygen, and adjust the operation of treatment equipment accordingly. For example, if the pH level of the water is outside the desired range, the PLC can control the dosing of chemicals to adjust it, ensuring the treated water meets regulatory standards. It can also manage the operation of pumps to ensure proper flow and pressure in the treatment system.

GE IC752SPL013-BA EX2100

Comparison with related models in the series

Compared with other GE EX2100 series PLC modules: Other modules in the EX2100 series may differ in terms of processing power, memory capacity, and I/O expansion capabilities. For example, some lower-end models may have a less powerful processor and limited memory, making them suitable for simple control applications. The IC752SPL013-BA EX2100, with its high-performance processor and sufficient memory, is better suited for more complex industrial processes that require fast and accurate control. Higher-end models in the series may offer additional features such as built-in motion control or advanced security functions, but the IC752SPL013-BA EX2100 provides a good balance between performance and cost for most standard industrial control applications.

Compared with similar products from other brands: GE’s IC752SPL013-BA EX2100 stands out due to its seamless integration with GE’s other industrial automation products, such as HMIs and SCADA systems. This integration ensures smooth data flow and easy system expansion. GE’s Proficy Machine Edition software is also highly regarded for its user-friendly interface and powerful programming capabilities, giving it an edge over some competing software. Additionally, GE’s global service and support network provides reliable assistance, ensuring that users can get help quickly in case of any issues. The rugged design and wide operating temperature range of the IC752SPL013-BA EX2100 also make it a competitive choice compared to similar products from other brands, especially in harsh industrial environments.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the IC752SPL013-BA EX2100, select a suitable location that is clean, dry, and free from excessive vibration, dust, and electromagnetic interference. Ensure the mounting surface is sturdy and can support the weight of the module and any connected I/O modules. Check the power supply to confirm it meets the 24 V DC requirement. Gather the necessary tools such as screwdrivers, wire strippers, and torque wrenches. Review the wiring diagrams and installation manual to familiarize yourself with the module’s connections and mounting requirements.

Commissioning process: Mount the PLC module securely on the designated surface. Connect the power supply cables, ensuring correct polarity. Connect the I/O modules and other devices according to the wiring diagrams, making sure all connections are tight and secure. Power on the module and check the status indicators to ensure it is operating correctly. Use the Proficy Machine Edition software to load the control program into the PLC. Test the program by simulating various input conditions and verifying that the output signals are correct. Calibrate any analog I/O modules as needed to ensure accurate measurement and control. Monitor the system’s operation for a period to ensure it is functioning properly before putting it into full operation.

Maintenance suggestions: Regularly inspect the IC752SPL013-BA EX2100 for physical damage, loose connections, or signs of overheating. Clean the module’s surface and ventilation ports to prevent dust accumulation, which can affect cooling. Check the status indicators periodically to monitor the module’s operation. Back up the control program regularly to prevent data loss in case of a module failure. Update the module’s firmware to the latest version when available, using the Proficy Machine Edition software, to benefit from performance improvements and bug fixes. If any faults or malfunctions occur, refer to the troubleshooting guide or contact GE’s technical support for assistance. Use only genuine GE spare parts when replacing components to ensure the module’s reliability and performance.

Service and guarantee commitment

GE provides a standard warranty period for the IC752SPL013-BA EX2100, covering manufacturing defects. Their global technical support team is available 24/7 to assist customers with installation, commissioning, and troubleshooting. Customers can access technical documentation, software updates, and support resources through GE’s online platforms. For complex issues, GE’s field service engineers can be dispatched to provide on-site support. GE also offers training programs to help customers learn how to program, install, and maintain the PLC module effectively. Additionally, extended warranty options and preventive maintenance services are available to ensure the long-term reliable operation of the module, minimizing downtime and maximizing productivity in industrial applications.