Description

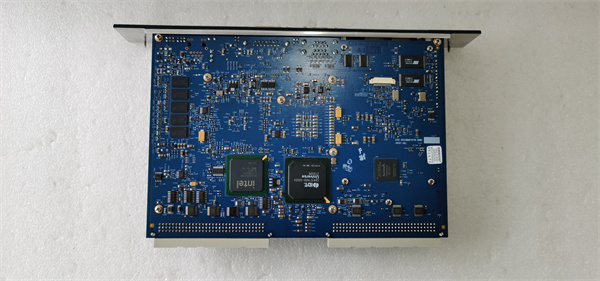

GE IC698CPE030 – HN

Detailed parameter table

| Parameter name | Parameter value |

| Product model | IC698CPE030 – HN |

| Manufacturer | Initially by GE Intelligent Platforms (GE IP), now under Emerson Automation following acquisition |

| Product category | Central Processing Unit (CPU) within the PACSystems RX7i series of Programmable Automation Controllers (PAC) |

| Processing speed | 600 MHz, enabled by a Pentium – M microprocessor |

| Memory | 64 MB of user memory (RAM) for real – time data processing and 64 MB of non – volatile user flash memory for storing programs, configurations, and data even during power outages |

| I/O capacity | Can manage up to 32 k bits of discrete input/output (I/O), suitable for handling on – off signals from sensors and actuators. Also supports 32 k words of analog I/O, allowing for the processing of continuous signals such as temperature, pressure, and flow rate |

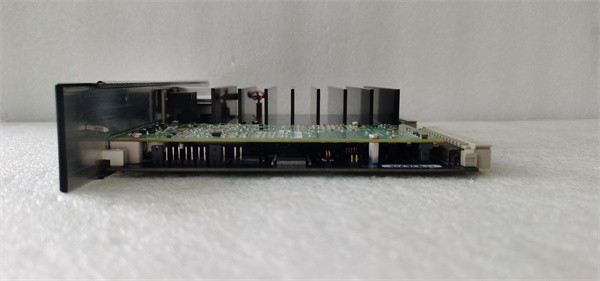

| Communication ports | Dual ethernet ports with auto – sensing capabilities for 10/100 mbps half/full – duplex network transmission. Supports protocols like SRTp, Modbus TCP (both server and client), and Ethernet Global Data (EGD). Additionally, it has one RS232 port, one RS485 port, and a station manager port, which support protocols such as Modbus RTU slave, SNP, and serial I/O |

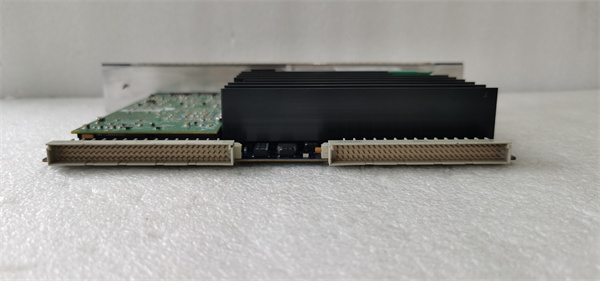

| Power requirements | Operates on voltages of +5 VDC, +12 VDC, or – 12 VDC. Draws a backplane current of 3.4 amps at 5 volts DC |

| Embedded features | Built – in web server and File Transfer Protocol (FTP) functionality, enabling remote monitoring and configuration. Supports up to 16 web server/FTP connections, facilitating easy access to the CPU for maintenance and control purposes |

| Programming languages | Compatible with ladder diagram, structured text, function block diagram, and C programming languages, providing flexibility for programmers with different skill sets and application requirements |

| Compatibility | Integrates well with the GE Fanuc family’s RX7i I/O rack system using the VME64 base architecture. Supports Series 90 – 70 discrete and analog I/O modules, as well as a wide range of other VME modules. Can communicate with various programmers and Human – Machine Interface (HMI) devices |

| Isolated communication ports | Features an isolated RS – 485 serial port, an isolated RS – 232 serial port, and an isolated RS – 232 ethernet station manager port, enhancing its reliability and performance in noisy industrial environments |

| Execution speed | Achieves a boolean processing speed of 0.069 milliseconds per 1,000 boolean contacts/coils, ensuring fast response times for control applications |

| Program blocks | Can accommodate up to 512 program blocks, with each block capable of holding up to 128 kb of memory, making it suitable for complex industrial control scenarios |

GE IC698CPE030-HN

Product introduction

The GE IC698CPE030 – HN is a high – performance central processing unit that has been a staple in industrial automation since its inception by GE Intelligent Platforms, now under the Emerson Automation umbrella. In the realm of industrial control systems, the need for a reliable, fast, and versatile CPU is crucial. The IC698CPE030 – HN rises to this challenge, acting as the brain of the PACSystems RX7i series.

Industrial processes are becoming increasingly complex, with the need to control multiple variables, communicate with a vast array of sensors and actuators, and integrate with higher – level systems for data analysis and decision – making. The IC698CPE030 – HN is designed to meet these demands. It serves as the core component that coordinates all the activities within the control system, ensuring seamless operation.

When the system is powered on, the IC698CPE030 – HN initiates a comprehensive self – diagnostic check. This self – test is vital as it verifies the integrity of the CPU’s hardware and software components. During the initialization phase, a series of LED lights on the module emit specific on – off patterns in a defined sequence. Once this initialization is successfully completed, the “OK” LED light starts blinking and then remains steadily on, indicating that the CPU is ready for operation.

Core advantages and technical highlights

High – speed processing: The 600 MHz Pentium – M microprocessor at the heart of the IC698CPE030 – HN enables rapid execution of control algorithms. This high processing speed is particularly beneficial in applications where real – time response is critical. For example, in a high – speed manufacturing line, the CPU can quickly process sensor data and send out control signals to adjust machinery operations, ensuring that production rates are maintained and product quality is not compromised. The fast boolean processing speed of 0.069 milliseconds per 1,000 boolean contacts/coils allows for quick decision – making based on digital input signals, such as detecting the status of limit switches or the state of relays.

Abundant memory resources: With 64 MB of user memory and 64 MB of non – volatile flash memory, the IC698CPE030 – HN can store a large number of programs, configurations, and data. The user memory is used for real – time data processing, allowing the CPU to handle complex calculations and operations during system runtime. The non – volatile flash memory ensures that important information, such as control programs and calibration data, is retained even in the event of a power failure. This eliminates the need for time – consuming re – programming and data restoration when power is restored, reducing downtime and improving overall system reliability.

Versatile communication capabilities: The dual ethernet ports, along with the multiple serial ports, provide extensive communication options. The ethernet ports support high – speed data transfer, making it easy to integrate the CPU into a plant – wide network. For instance, it can communicate with other control devices, such as programmable logic controllers (PLCs), distributed control systems (DCS), and supervisory control and data acquisition (SCADA) systems. The ability to support protocols like Modbus TCP and Ethernet Global Data enables seamless data exchange between different components in the industrial network. The serial ports, on the other hand, are useful for connecting to legacy devices or sensors and actuators that use serial communication protocols, ensuring compatibility with existing infrastructure in many industrial plants.

Flexible programming options: The support for multiple programming languages – ladder diagram, structured text, function block diagram, and C – gives programmers the freedom to choose the most suitable language for their application. Ladder diagram is a popular choice for those with a background in electrical engineering, as it closely resembles traditional relay – logic diagrams. Structured text and C are more suitable for complex algorithms and data – intensive applications, allowing for more precise control and optimization. Function block diagram is useful for representing complex control functions as a set of interconnected blocks, making the control logic easier to understand and maintain. This flexibility in programming languages broadens the pool of potential users and simplifies the development process for different types of industrial control applications.

Compatibility and expandability: The IC698CPE030 – HN’s compatibility with the GE Fanuc RX7i I/O rack system and a wide range of I/O and VME modules makes it highly expandable. In a large – scale industrial plant, as the control requirements grow, additional I/O modules can be easily added to the system. For example, if new sensors or actuators need to be connected, discrete or analog I/O modules can be installed in the RX7i I/O rack and integrated with the IC698CPE030 – HN. This expandability ensures that the control system can adapt to changing industrial processes and technological advancements without the need for a complete overhaul, providing long – term cost – effectiveness.

Typical application scenarios

Manufacturing industry: In a manufacturing plant, the IC698CPE030 – HN can be used to control various production processes. For example, in an automotive assembly line, it can manage the movement of robotic arms, conveyor belts, and other automated machinery. The CPU receives input signals from sensors that detect the position of parts, the status of machinery, and the quality of products. Based on this data, it sends out control signals to ensure that the assembly process is carried out smoothly and accurately. It can also communicate with the plant’s management system to provide real – time production data, such as the number of units produced, the cycle time, and any production – related issues, enabling better production planning and quality control.

Power generation facilities: In power plants, whether they are fossil – fuel – based, nuclear, or renewable energy – powered, the IC698CPE030 – HN plays a crucial role in controlling the power generation process. It can monitor and control parameters such as the speed of turbines, the temperature of generators, and the flow rate of cooling water. For example, in a gas – fired power plant, the CPU receives speed sensor data from the gas turbine. If the turbine speed deviates from the optimal value, the IC698CPE030 – HN can adjust the fuel supply to the turbine to maintain stable power generation. It also communicates with other components in the power plant, such as the switchgear and the energy management system, to ensure efficient power distribution and grid integration.

Water and wastewater treatment plants: In water treatment plants, the IC698CPE030 – HN is used to control the water treatment process. It monitors parameters such as water quality (pH, turbidity, chlorine levels), the flow rate of water through different treatment stages, and the operation of pumps and valves. For instance, if the pH level of the incoming water is too low, the CPU can send signals to dosing pumps to add the appropriate chemicals to adjust the pH. In wastewater treatment plants, it can control the activation of sludge treatment processes, ensuring that the treated water meets environmental standards before being discharged. The CPU also communicates with the plant’s supervisory system to provide data for process optimization and compliance reporting.

GE IC698CPE030-HN

Related model recommendations

GE IC698CRE030 – HN: This CPU is also part of the PACSystems RX7i series and offers features such as Hot Standby Redundancy (HSB). In applications where high availability is critical, such as in power plants or large – scale manufacturing facilities, the IC698CRE030 – HN can be used in a redundant configuration with the IC698CPE030 – HN. In case of a failure in the primary CPU (IC698CPE030 – HN), the standby CPU (IC698CRE030 – HN) can take over seamlessly, minimizing downtime. It also has similar memory and communication capabilities, making it a suitable companion for the IC698CPE030 – HN in redundant setups.

GE Series 90 – 70 I/O modules: These modules are highly compatible with the IC698CPE030 – HN. For example, the discrete I/O modules can be used to interface with sensors and actuators that provide or require digital on – off signals. In a manufacturing application, a Series 90 – 70 discrete input module can be used to connect limit switches, proximity sensors, and pushbuttons to the IC698CPE030 – HN, while a discrete output module can be used to control relays, solenoids, and motor starters. The analog I/O modules in the Series 90 – 70 range are useful for connecting to sensors and actuators that deal with continuous signals, such as temperature sensors, pressure transducers, and variable – speed drives.

GE HMI devices: Human – Machine Interface (HMI) devices are essential for operators to interact with the control system. GE offers a range of HMI devices that work well with the IC698CPE030 – HN. These HMI devices can display real – time process data, such as the status of machines, the values of process variables, and any alarms or warnings. Operators can also use the HMI to input commands, change setpoints, and configure the control system. For example, a GE touch – screen HMI can be used to provide an intuitive interface for operators in a power generation plant to monitor and control the power generation process.

Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that all power sources related to the control system are turned off. This includes the main power supply and any local power sources for associated devices. Check the VME64 – compliant backplane where the IC698CPE030 – HN will be installed for any signs of damage or loose connections. Clean the backplane slots to ensure a proper electrical connection. Verify that the power supply available for the CPU is within the specified voltage range (+5 VDC, +12 VDC, or – 12 VDC). Use anti – static wrist straps when handling the CPU module to prevent electrostatic discharge, which could damage the sensitive electronic components. Prepare the communication cables for the ethernet and serial ports, ensuring that they are of the correct type and properly shielded. Familiarize yourself with the installation diagrams provided in the user manual, which clearly show the pin – out details for the various ports and the correct orientation of the module in the backplane.

Commissioning steps: Mount the IC698CPE030 – HN in the appropriate slot on the VME64 backplane using the provided mounting hardware and secure it firmly. Connect the power supply wires to the module according to the wiring diagram in the user manual. Connect the communication cables for the ethernet and serial ports to their respective devices, such as network switches, serial devices, or HMIs. Power on the control system and observe the LED lights on the CPU module. The power LED should be illuminated steadily, indicating that the module is receiving power. The ethernet status LEDs should show the correct link and activity status if the network connections are properly configured. Use the appropriate programming software, such as Proficy Machine Edition, to configure the CPU. Set up parameters such as the communication protocols for the ethernet and serial ports, the I/O module addresses, and the initial control programs. Test the communication between the CPU and the connected devices by sending and receiving sample data. Calibrate any connected sensors or actuators if necessary by following the calibration procedures in the programming software.

Maintenance suggestions: Regularly perform visual inspections of the IC698CPE030 – HN. Check for any loose connections, signs of overheating (such as discolored components or a burning smell), or physical damage to the module’s enclosure. Clean the module periodically to remove dust and debris, as these can accumulate and cause electrical interference or overheating, especially in industrial environments with high levels of particulate matter. Monitor the CPU’s performance through the control system’s diagnostic software. Look for any abnormal behavior, such as high CPU utilization, communication errors, or incorrect control actions. If a problem is detected, first check the wiring connections to ensure they are secure. If the issue persists, use the programming software to perform self – diagnostic tests on the module. In case of a component failure, replace the faulty component with a genuine replacement part. For example, if the flash memory on the module fails, obtain a compatible GE – branded flash memory module and follow the step – by – step instructions in the user manual to replace it without causing any damage to other components on the board. Also, consider replacing the lithium battery pack (part IC698ACC701) as scheduled to avoid memory loss, as the battery maintains program and data memory and operates the calendar clock during power outages.

Service and guarantee commitment

Emerson Automation, the current manufacturer of the IC698CPE030 – HN, offers a comprehensive service and guarantee package. They provide a standard warranty period, typically covering manufacturing defects and performance issues under normal operating conditions. Their global technical support team is available around the clock to offer assistance. In case of problems, they can perform remote diagnostics and troubleshooting via secure connections. If the issue cannot be resolved remotely, Emerson can dispatch on – site technicians to the location.

Customers have access to a wealth of online resources, including detailed user manuals, technical specifications, and configuration guides for the IC698CPE030 – HN. Training courses are also available, either online or in – person, to help users understand the module’s installation, configuration, and maintenance. These training programs are designed to enhance the user’s skills and knowledge, enabling them to make the most of the CPU’s capabilities. Extended warranty options may be available, which can provide additional coverage and services such as preventive maintenance checks. This commitment to support ensures that customers can rely on the IC698CPE030 – HN for reliable and efficient operation in their industrial applications.