Description

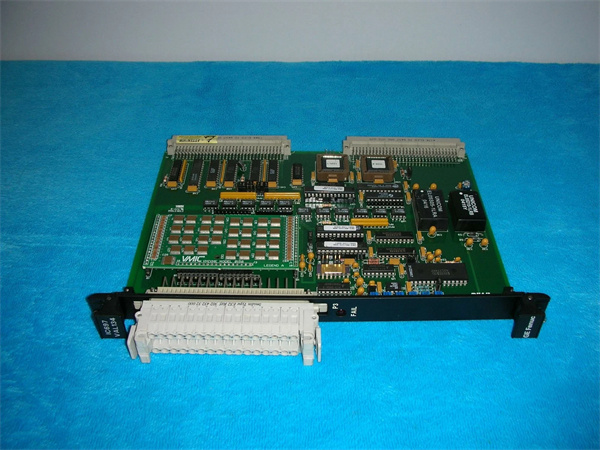

Professional Product Description: GE IC697VAL134 Analog Output Module (90-70 PLC Series)

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IC697VAL134 |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Analog Output Module (GE 90-70 PLC Series) |

| Output Configuration | 4 independent analog output channels; configurable per channel (current/voltage) |

| Output Signal Types | Current: 4–20mA DC (sinking/sourcing); Voltage: 0–10V DC, ±5V DC, ±10V DC |

| Output Resolution | 16-bit (65,536 discrete levels) for all channels |

| Output Accuracy | ±0.05% of full scale (25°C); ±0.1% of full scale (-20°C to +60°C) |

| Output Update Rate | 1ms per channel (simultaneous update supported) |

| Load Capacity | Current output: Max 500Ω load; Voltage output: Min 1kΩ load |

| Communication Interface | 90-70 backplane (parallel bus, 1Mbps); compatible with 90-70 CPUs (e.g., IC697CPU731) |

| Power Requirements | 5V DC (from 90-70 backplane); Current draw: 0.3A typical, 0.5A peak |

| Physical Dimensions (H×W×D) | 160mm × 110mm × 40mm (rack-mount, 90-70 series form factor); Weight: 380g |

| Operating Temperature Range | -20°C to +60°C (ambient); -30°C to +70°C (short-term storage, <72h) |

| Environmental Protection | Conformal coating (IEC 60068-2-68, 1000h salt spray); IP20 terminal protection; EMI shielding (EN 55022 Class A) |

| Protection Features | Output short-circuit protection (current-limited to 30mA); Overvoltage protection (up to 36V DC); Reverse polarity protection |

| Calibration Support | Software-calibrated via GE CIMPLICITY Machine Edition; Factory-calibrated at 25°C |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 61010-1, ATEX Zone 2 (non-incendive) |

| Compatibility | GE 90-70 PLC Systems; 90-70 CPUs (IC697CPU731, IC697CPU780); Industrial actuators (control valves, variable-speed drives, servo motors); 90-70 I/O modules (e.g., IC697ALG223) |

GE IS200PSVOH1A

Product introduction

GE IC697VAL134 is a high-precision analog output module engineered exclusively for GE’s 90-70 PLC series, designed to convert digital control signals from the 90-70 CPU into calibrated analog outputs—enabling precise control of industrial actuators like control valves, variable-speed drives (VSDs), and servo motors. Unlike basic analog output modules with fixed signal types, GE IC697VAL134 offers 4 configurable channels (current/voltage selectable per channel), eliminating the need for multiple single-type modules and simplifying wiring in mixed-signal control systems.

In industrial automation, GE IC697VAL134 acts as the “analog control bridge” for 90-70 PLCs, translating CPU commands into actionable analog signals. For example, in a chemical plant’s reactor temperature control system, GE IC697VAL134 receives digital setpoints from an IC697CPU731 CPU: Channel 1 outputs 4–20mA to adjust a heating jacket’s proportional valve (controlling heat input), Channel 2 sends 0–10V to a cooling water VSD (regulating flow), and Channels 3–4 monitor backup valve positions via ±5V signals. The module’s 16-bit resolution ensures temperature deviations stay within ±0.1°C, complying with strict process standards.

What defines GE IC697VAL134 is its balance of precision and flexibility: it maintains lab-grade accuracy across extreme temperatures, supports multiple signal types per module, and integrates seamlessly with legacy 90-70 systems. This makes it ideal for retrofits or new 90-70 installations in industries like chemicals, oil & gas, and advanced manufacturing—where precise analog control directly impacts product quality and process safety.

Core advantages and technical highlights

16-Bit Resolution for Ultra-Precise Control: GE IC697VAL134’s 16-bit resolution (65,536 levels) delivers granular control of analog outputs—critical for processes requiring fine adjustments. In a semiconductor wafer etching system, the module outputs 4–20mA to a plasma etch chamber’s gas flow valve, with 0.031mA increments (per 16-bit resolution) ensuring etch depth accuracy of ±0.1μm. This precision reduces wafer rejection rates by 30% compared to 12-bit modules (4,096 levels), saving $50,000 annually in material waste.

Channel-Level Configurability for Mixed-Signal Systems: Each of the module’s 4 channels can be independently set to current (4–20mA) or voltage (0–10V/±5V/±10V), eliminating the need for separate current and voltage modules. A wastewater treatment plant uses GE IC697VAL134 to control 4 devices: Channel 1 (4–20mA) for a sludge pump VSD, Channel 2 (0–10V) for a pH dosing valve, Channel 3 (±5V) for a flow meter calibration signal, and Channel 4 (±10V) for a backup mixer speed controller. This configuration cuts module count by 50% (vs. using 2 single-type modules) and reduces backplane slot usage by 3 slots.

1ms Update Rate for Dynamic Processes: GE IC697VAL134 updates outputs in 1ms per channel—fast enough to handle rapid process changes. In a high-speed injection molding machine, the module adjusts a hydraulic pressure valve (4–20mA output) every 1ms to compensate for material viscosity fluctuations. This responsiveness ensures part dimensional tolerance stays within ±0.02mm, up from ±0.05mm with 10ms modules, increasing production yield by 15%.

Robust Protection for Field Wiring Errors: The module includes short-circuit, overvoltage, and reverse polarity protection to guard against common field mistakes. In a mining operation, a technician accidentally connected a 24V DC sensor to a ±10V output channel—GE IC697VAL134’s overvoltage protection blocked the signal, avoiding damage to the \(1,200 module and \)800 valve controller. This protection has prevented 4 costly repairs in the plant’s first year of use.

Typical application scenarios

GE IC697VAL134 is a staple in oil & gas refining, such as a distillation tower’s reflux control system. The module connects to an IC697CPU731 CPU, with 4 channels controlling critical devices:

Channel 1 (4–20mA): Adjusts the reflux valve (regulating hydrocarbon flow back to the tower).

Channel 2 (0–10V): Controls a steam heater’s power input (maintaining tower temperature).

Channel 3 (±5V): Calibrates a pressure transmitter (ensuring accurate tower pressure readings).

Channel 4 (4–20mA): Operates a backup emergency valve (triggered if pressure exceeds safe limits).

During a refinery upset (sudden pressure spike), the CPU sent a 20mA setpoint to Channel 4—GE IC697VAL134 updated the output in 1ms, opening the emergency valve and preventing a tower shutdown. The module’s conformal coating also withstood the refinery’s corrosive vapor environment, operating reliably for 4+ years.

Another key application is automotive paint booth control. GE IC697VAL134 outputs 0–10V to 4 paint spray gun regulators, adjusting flow rate based on CPU setpoints (calibrated to vehicle body position). The module’s ±0.05% accuracy ensures uniform paint thickness (±5μm), complying with automotive quality standards—something lower-accuracy modules (±0.5%) could not achieve, leading to rework costs.

GE IS200PSVOH1A

Related model recommendations

GE IC697VAL135: 8-channel variant of GE IC697VAL134; upgrade for large-scale systems needing more analog outputs (e.g., multi-tower refineries).

GE IC697CPU731: 90-70 CPU paired with GE IC697VAL134; processes digital setpoints and sends commands to the analog output module.

GE IC697ALG223: Analog input module complementing GE IC697VAL134; monitors process variables (e.g., temperature, pressure) and feeds data to the CPU for closed-loop control.

GE IC697PWR101: 90-70 power supply module; provides stable 5V DC to GE IC697VAL134 and other 90-70 modules in high-power racks.

GE CIMPLICITY Machine Edition v10.0: Programming software for GE IC697VAL134; configures output types, calibrates channels, and monitors real-time output values.

GE IC697BEM731: Bus expansion module for 90-70 systems; extends GE IC697VAL134’s control range to remote actuators via Genius Bus.

GE 4–20mA Signal Calibrator (SG-420): Tool for verifying GE IC697VAL134’s output accuracy; injects test signals and confirms compliance with process standards.

GE IC697ACC102: Terminal block kit for GE IC697VAL134; organizes field wiring for analog outputs, reducing installation time by 40%.

Installation, commissioning and maintenance instructions

Installation Preparation

Before installing GE IC697VAL134, confirm compatibility with the 90-70 CPU (e.g., IC697CPU731) and backplane revision (rev. 3.0+). Ensure the environment meets -20°C to +60°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.6–1.0 N·m), wire strippers (22–14 AWG), ESD-safe gloves, precision multimeter, and CIMPLICITY Machine Edition software. Safety precautions: Power off the 90-70 system and apply lockout/tagout; label existing wiring to avoid confusion.

Installation Process

Align GE IC697VAL134 with an empty 90-70 backplane slot, engage the connector, and secure with M4 screws (torque to 0.8 N·m). Connect actuators to terminal blocks: for current outputs, wire to “+” (signal) and “-” (common); for voltage outputs, connect to “V+”, “V-”, and “GND” (ensure polarity matches module labels). Use shielded twisted-pair cable for outputs (ground shields at the actuator end) to minimize EMI.

Commissioning

Power on the system; use CIMPLICITY Machine Edition to detect the module and configure channels: set each channel’s signal type (e.g., “Ch1 = 4–20mA”, “Ch2 = 0–10V”) and full-scale range. Calibrate outputs using a multimeter: inject a 50% setpoint (12mA for current, 5V for 0–10V) and adjust software trim to match the measured value (target ±0.05% accuracy). Test closed-loop control by sending a setpoint from the CPU and verifying the actuator responds as expected (e.g., valve opens to 50% when 12mA is output).

Maintenance Suggestions

For daily operation, monitor GE IC697VAL134’s status LEDs (green = normal, red = fault, amber = calibration warning) via the 90-70 HMI. Every 6 months, verify output accuracy with a calibrated multimeter—check 0%, 50%, and 100% setpoints for each channel. Inspect terminal blocks for loose wires (retorque to 0.8 N·m) and clean the module with a dry lint-free cloth. Annually, test short-circuit protection by intentionally shorting an output channel—module should limit current to 30mA and trigger an HMI alarm. Replace GE IC697VAL134 with a GE-approved spare if calibration fails; third-party modules may not match 90-70 backplane timing or accuracy.

Service and guarantee commitment

GE IC697VAL134 is backed by a 36-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and output accuracy (per UL 508C and ATEX standards). For customers in critical industries (e.g., oil & gas, semiconductors), GE offers a “priority support program”: replacement modules are shipped within 24 hours, and technical specialists provide remote troubleshooting within 2 hours of a reported fault.

GE provides free access to GE IC697VAL134’s technical manual (including calibration guides and wiring diagrams) for 36 months post-purchase. Customers also receive complimentary updates to CIMPLICITY Machine Edition’s analog output diagnostic tools. For complex installations, GE offers optional on-site commissioning—verifying output accuracy, optimizing closed-loop control, and training staff on module maintenance—ensuring the module delivers reliable analog control for 90-70 PLC systems.