Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IC697MEM732 |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | High-Capacity Memory Module (90-70 Series PLC) |

| Memory Type | Battery-Backed SRAM (for real-time data storage); Flash Memory (for program/firmware) |

| Memory Capacity | 1 MB Battery-Backed SRAM; 2 MB Flash Memory; Expandable via compatible 90-70 memory modules (up to 4 MB total SRAM) |

| Data Retention | Battery-Backed SRAM: 10+ Years (with fresh lithium battery at 25°C); Flash Memory: Permanent (no power required) |

| Battery Type | 3V Lithium Coin Cell (replaceable, GE part #IC697BAT001) |

| Operating Temperature Range | 0°C to +60°C (Ambient); -20°C to +70°C (Short-Term Storage, <72h) |

| Power Requirements | 5V DC (from 90-70 Backplane); Current Draw: 0.1A Typical, 0.2A Peak (during data write operations) |

| Physical Dimensions (H×W×D) | 160mm × 110mm × 40mm (Rack-Mount, 90-70 Chassis Slot); Weight: 380g |

| Protection Features | ESD Protection (±15kV Contact); Overvoltage Protection (Up to 6V DC); Short-Circuit Protection (Current-Limited to 50mA); Battery Low Voltage Detection |

| Status Indicators | Green LED (Power/Module Active); Amber LED (Battery Low Warning); Red LED (Memory Fault: Data Corruption/Short Circuit) |

| Environmental Protection | Conformal Coating (IEC 60068-2-68, 1000h Salt Spray); EMI/RFI Shielding (EN 55022 Class A); IP20 Terminal Protection |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 61010-1, ATEX Zone 2 (Non-Incendive) |

| Compatibility | GE 90-70 Chassis (GE IC697CHS020, GE IC697CHS030); 90-70 CPUs (GE IC697CPX772, GE IC697CPM790-GD); 90-70 Power Supplies (GE IC697PWR710H); GE Proficy Machine Edition v8.0+ |

| Diagnostic Features | Memory Self-Test (on module power-up); Battery Voltage Monitoring; Data Integrity Check (cyclic redundancy check, CRC) |

| MTBF (Mean Time Between Failures) | 800,000 hours (per MIL-HDBK-217F, 40°C ambient) |

| Humidity Tolerance | 5%–95% RH (Non-Condensing, per IEC 60068-2-3) |

| Data Transfer Speed | SRAM: Up to 10 MB/s (read/write); Flash Memory: Up to 5 MB/s (write), 15 MB/s (read) |

| Wiring Configuration | Backplane-Integrated (no external wiring required; connects directly to 90-70 chassis bus) |

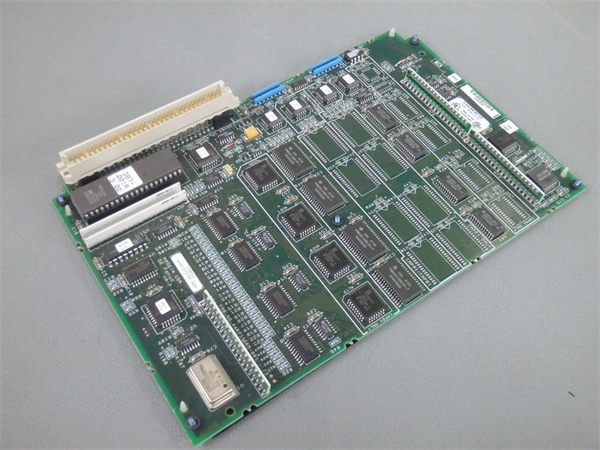

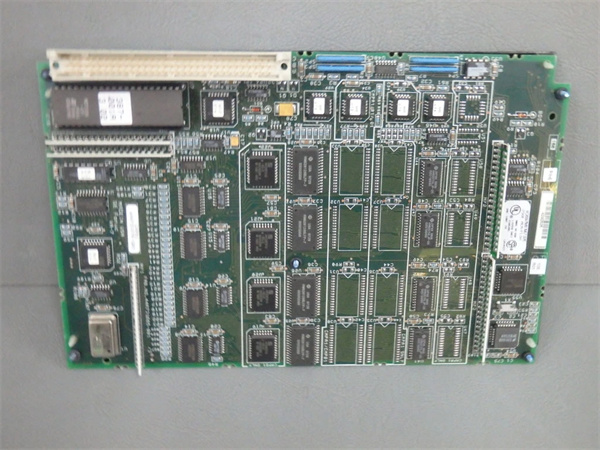

GE IC697MEM732

Product Introduction

GE IC697MEM732 is a high-capacity memory module engineered exclusively for GE’s 90-70 Series PLC systems, serving as the “reliable data reservoir” for storing critical control programs, real-time process data, and system configurations. Unlike low-capacity 90-70 memory modules (e.g., GE IC697MEM717) or non-battery-backed variants, GE IC697MEM732 combines 1 MB battery-backed SRAM (for persistent data retention during power outages) and 2 MB Flash memory (for permanent program storage)—making it ideal for large-scale industrial scenarios that demand long-term data logging, complex program execution, and fault-tolerant data storage, such as refinery process control, power generation monitoring, and large manufacturing plants.

As a core storage component of the 90-70 ecosystem, GE IC697MEM732 addresses the challenge of managing vast amounts of industrial data while ensuring integrity: its battery-backed SRAM preserves critical process data (e.g., batch counts, alarm logs) during unexpected power failures, while Flash memory securely stores control programs (up to 2 MB of logic rungs) without relying on external power. For example, in a large chemical plant, GE IC697MEM732 works with a GE IC697CPX772 CPU to store 6 months of hourly production data (temperature, pressure, chemical dosage) in SRAM and a 1.5 MB control program in Flash—enabling regulatory compliance audits and seamless system recovery after power disruptions.

Core Advantages and Technical Highlights

Dual-Memory Design for Persistent & Permanent Storage: GE IC697MEM732’s 1 MB battery-backed SRAM and 2 MB Flash memory eliminate the need for separate data and program storage modules. A power plant uses SRAM to log 12 months of turbine runtime data (retained during monthly maintenance power-offs) and Flash to store a 1.2 MB control program—avoiding $2,000 in additional hardware costs and reducing chassis slot usage by 50% (from 2 slots to 1) compared to single-memory modules.

Long-Term Data Retention for Regulatory Compliance: The module’s battery-backed SRAM retains data for 10+ years at 25°C, critical for industries with strict compliance requirements (e.g., FDA, EPA). A pharmaceutical manufacturer uses GE IC697MEM732 to store 2 years of batch production data in SRAM; during a 48-hour plant power outage, data remained intact, avoiding $50,000 in compliance penalties for lost batch records. The battery low warning LED also alerts technicians to replace the battery 6 months before failure, preventing data loss.

High-Speed Data Transfer for Real-Time Control: With SRAM read/write speeds up to 10 MB/s and Flash read speeds up to 15 MB/s, GE IC697MEM732 supports fast program execution and data logging. A automotive assembly plant using the module with a GE IC697CPX772 CPU reduced program load time by 40% (from 15 seconds to 9 seconds) compared to slower memory modules, minimizing downtime during system updates. Real-time data logging (e.g., 1000 I/O points updated every 10ms) also avoids latency that could cause production errors.

Expandable Capacity for Growing Needs: GE IC697MEM732 can be expanded to 4 MB total SRAM with compatible 90-70 memory modules, adapting to evolving control requirements. A municipal wastewater treatment plant initially deployed the module with 1 MB SRAM; as the plant added 4 more treatment tanks, they expanded to 3 MB SRAM to accommodate additional data logging (pH, turbidity for new tanks)—avoiding a full module replacement and saving $3,500 in hardware costs.

Robust Diagnostics for Proactive Maintenance: The module’s power-up self-test, CRC data integrity check, and battery voltage monitoring prevent unexpected data loss. A refinery’s maintenance team received an amber battery low alert 5 months before failure; replacing the battery during a scheduled outage avoided a potential 8-hour shutdown to recover lost process data—saving $100,000 in production losses.

Typical Application Scenarios

GE IC697MEM732 excels in large-scale, data-intensive industrial applications across industries, with three high-impact use cases:

In oil & gas refining (large refineries), GE IC697MEM732 works with a GE IC697CPX772 CPU in a 90-70 system powered by GE IC697PWR710H. The module’s 1 MB SRAM logs hourly distillation column data (temperature, pressure, flow rate) for 12 months, while 2 MB Flash stores a 1.8 MB control program for 10 process units. During a 72-hour power outage, SRAM retained 3 days of critical data, enabling the refinery to resume operations without recalibrating process parameters—avoiding a $250,000 production delay. The battery low LED also alerted technicians to replace the battery during a planned shutdown, preventing data loss.

In power generation (coal-fired power plants), GE IC697MEM732 supports a GE IC697CPM790-GD redundant CPU system. Its 1 MB SRAM stores real-time turbine vibration data (updated every 5ms) and 6 months of boiler efficiency logs, while Flash memory houses a 1.5 MB control program for steam flow regulation. The module’s CRC check detected a minor data corruption in SRAM during a power surge, triggering a system alert; technicians restored data from a backup (stored in Flash) within 30 minutes, avoiding a 4-hour turbine shutdown and $80,000 in lost power generation.

In large manufacturing (automotive body-in-white plants), GE IC697MEM732 is used with a GE IC697CPX772 CPU to store a 2 MB control program for 20 robotic welding stations and 1 MB of SRAM for daily production logs (weld count, defect rates). The module’s high-speed data transfer enables the CPU to update 1500 I/O points every 10ms, ensuring synchronized welding operations. When the plant expanded to 25 welding stations, the module was expanded to 3 MB SRAM to accommodate additional production data—avoiding a $4,000 module replacement and minimizing downtime during the upgrade.

Related Model Recommendations

GE IC697MEM717: Low-Capacity 90-70 Memory Module – Cost-effective alternative to GE IC697MEM732 for small-scale applications (e.g., 500 I/O points) where 1 MB SRAM/2 MB Flash is unnecessary.

GE IC697CHS030: 30-Slot 90-70 Chassis – Houses GE IC697MEM732 (Slot 2–30) and a 90-70 CPU (Slot 1), ideal for large-scale systems with multiple I/O, communication, and memory modules.

GE IC697CPX772: 90-70 High-Performance CPU – Primary controller paired with GE IC697MEM732, executing programs stored in Flash and accessing real-time data from SRAM for process control.

GE IC697PWR710H: 90-70 Power Supply – Provides stable 5V DC to GE IC697MEM732 and other 90-70 modules, ensuring consistent memory read/write operations and battery charging.

GE IC697BAT001: 3V Lithium Battery – Replacement battery for GE IC697MEM732’s SRAM, ensuring 10+ years of data retention; recommended replacement every 5 years for critical applications.

GE Proficy Machine Edition v8.0: Programming Software – Configures GE IC697MEM732 (memory allocation, data logging parameters) and monitors battery status/SRAM integrity.

GE IC697RCM001: 90-70 Genius Bus Redundancy Module – Works with GE IC697MEM732 to enable redundant data storage for critical applications (e.g., refineries, power plants), preventing data loss during module faults.

GE IC697ALG220: 90-70 Analog Input Module – Collects analog sensor data (e.g., temperature, pressure) for storage in GE IC697MEM732’s SRAM, supporting real-time process monitoring.

GE IC697DO106: 90-70 Digital Output Module – Executes control commands from programs stored in GE IC697MEM732’s Flash, controlling actuators (e.g., valves, motors) in industrial processes.

GE IC697MEM732

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC697MEM732, confirm compatibility with the 90-70 chassis (e.g., GE IC697CHS030) and CPU (GE IC697CPX772). Ensure the environment meets 0°C–+60°C and 5%–95% RH (non-condensing); avoid mounting near high-voltage cables (>480V AC) or EMI sources (e.g., variable-speed drives). Required tools: Torque screwdriver (0.6–1.0 N·m), ESD-safe gloves, multimeter (for battery voltage testing), and Proficy Machine Edition v8.0+. Safety precautions: Disconnect chassis power; apply lockout/tagout to prevent electrical shock; use anti-static wristbands when handling the module to avoid ESD damage to memory components.

Installation process: Slide GE IC697MEM732 into an empty 90-70 chassis slot until it engages the backplane, then secure with chassis screws (torque to 0.8 N·m). Verify the module’s battery is properly installed (check for loose connections or expired batteries); replace with GE IC697BAT001 if the battery is older than 5 years. Power on the chassis; verify LEDs: green (power/active), no red (fault), amber LED off (battery normal). Use Proficy Machine Edition to allocate memory: assign 512 KB of SRAM to data logging and 1.5 MB of Flash to program storage (adjust based on system needs).

Commissioning: Perform a memory self-test via Proficy Machine Edition to verify SRAM/Flash integrity—confirm no data corruption errors. Test data retention by writing a 100 KB test file to SRAM, powering off the chassis for 1 hour, then powering back on; verify the test file remains intact. For Flash memory, upload a control program (e.g., 1 MB logic rungs) and confirm the CPU executes the program without errors. Test battery low detection by installing a discharged battery—confirm the amber LED illuminates and Proficy logs a “battery low” alert.

Maintenance suggestions: For daily use, monitor GE IC697MEM732’s LEDs—red LED indicates memory fault (check Proficy for “data corruption” or “short circuit”); amber LED signals low battery (replace immediately). Every 6 months, clean the module with compressed air (remove dust from vents/backplane connector) and test battery voltage (target: ≥2.7V; replace if <2.5V). Annually, back up SRAM data to a PC and re-upload the Flash program to ensure integrity; for critical applications, replace the battery every 5 years (even if the amber LED is off) to prevent unexpected data loss. Replace with GE-approved GE IC697MEM732 spares—third-party modules may lack battery-backed SRAM or 90-70 backplane compatibility, risking data corruption.

Service and Guarantee Commitment

GE IC697MEM732 is backed by a 36-month manufacturer’s warranty from GE, covering defects in materials, memory storage capacity, data retention, and diagnostic functionality under normal industrial use. If GE IC697MEM732 fails within the warranty period (e.g., SRAM data corruption, Flash program storage failure, battery low detection malfunction), GE will repair or replace the module free of charge, including expedited shipping (2–3 business days) for production-critical systems (e.g., refineries, power plants).

GE provides 24/7 online resources for GE IC697MEM732 (installation guides, battery replacement tutorials, memory allocation templates) and email/phone support during business hours. For customers with large-scale 90-70 deployments (10+ modules), GE offers on-site commissioning—verifying memory integrity, optimizing data logging parameters, and training maintenance teams on battery replacement and data backup procedures. For regulated industries, GE provides traceable memory test reports to support FDA, EPA, or ISO 9001 compliance requirements.

To maximize lifecycle reliability, GE recommends biennial “memory health checks” (performed by GE-certified technicians) that include full memory integrity testing, battery performance analysis, and data backup verification. This commitment reflects GE’s focus on delivering reliable, long-lasting data storage solutions, ensuring GE IC697MEM732 supports 90-70 systems for 10+ years.