Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

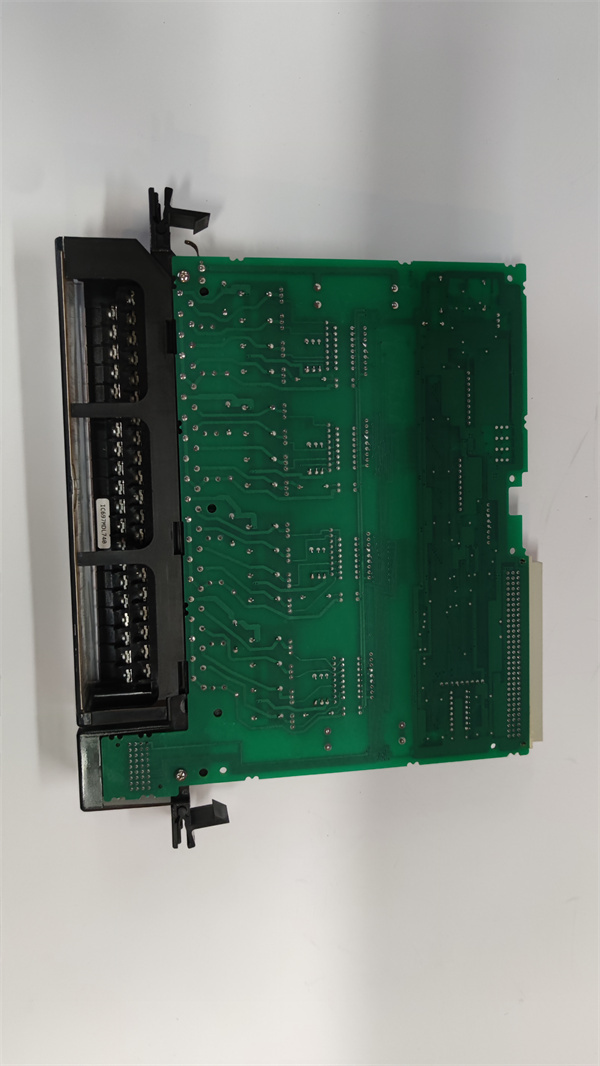

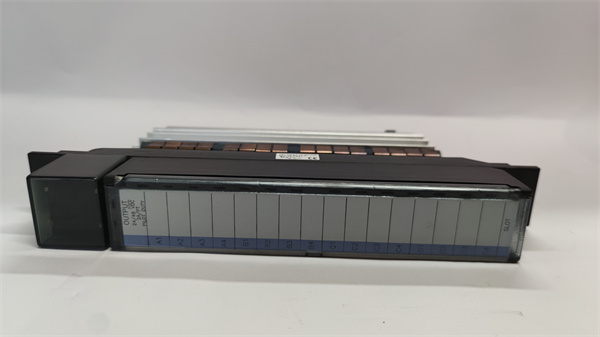

| Product model | GE IC697MDL740 |

| Manufacturer | GE Industrial (Series 90-70 Product Line) |

| Product category | Compact Digital Output Module (for Series 90-70 PLC Systems) |

| Output channels | 16 independent channels (relay output, Form C: NO/NC contacts) |

| Output type | Electromechanical relays (suitable for AC/DC mixed loads) |

| Per-channel load capacity | 2 A @ 24 V DC; 2 A @ 120 V AC; 1 A @ 240 V AC (resistive load) |

| Switching voltage range | 5–240 V AC/DC |

| Response time | ≤10 ms (turn-on); ≤5 ms (turn-off) |

| Protection features | Per-channel overcurrent protection (3 A trip), short-circuit protection, relay contact wear detection |

| Power supply | Derived from Series 90-70 chassis (5V DC logic power: 80mA max; 24V DC load power: external) |

| Operating temperature range | 0°C to 60°C (32°F to 140°F); Storage: -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions | 44.5 mm (W) × 165.1 mm (H) × 228.6 mm (D) (1.75 in × 6.5 in × 9.0 in) |

| Installation method | Series 90-70 chassis mounting (compatible with 4-slot to 16-slot chassis; 1 slot required) |

| Diagnostic functions | Channel-level LED indicators (red = energized), relay fault logging (via Proficy Machine Edition) |

| Compatibility | All Series 90-70 chassis (IC697CHS730, IC697CHS750), CPUs (IC697CPU770, IC697CPM915), and power supplies (IC697PWR710F, IC697PWR720) |

| Weight | 1.0 kg (2.2 lbs) |

| Compliance standards | UL 508, IEC 60947-5-1, CE (low-voltage directive) |

GE IC697MDL740

Product Introduction

The GE IC697MDL740 is a compact 16-channel digital output module in GE’s Series 90-70 PLC family, designed to serve as the “small-scale discrete control interface” for industrial automation systems—connecting Series 90-70 CPUs to low-quantity execution devices (e.g., small motors, solenoid valves, status indicators). Unlike the high-density IC697MDL750 (32 channels), the GE IC697MDL740 optimizes for systems with limited load counts (8–16 devices), avoiding channel waste and reducing costs. It is ideal for standalone equipment like small CNC lathes, independent HVAC units, or low-volume packaging machines.

Technical positioning for industries requiring “right-sized” discrete control (e.g., small workshops, standalone equipment manufacturers), the GE IC697MDL740 retains the core reliability of Series 90-70 modules: electromechanical relays support mixed AC/DC loads (no external converters needed), and it pairs seamlessly with entry-level components—powered by IC697PWR710F (chassis logic power) and controlled by IC697CPU770 (CPU). In automation architectures, the GE IC697MDL740 acts as a “compact driver hub,” fitting in ultra-small chassis (e.g., 4-slot models) and simplifying wiring for small device clusters—critical for space-constrained installations like machine-side control boxes.

Core Advantages and Technical Highlights

16-Channel Compact Design for Small Systems: The GE IC697MDL740’s 16 channels match the load count of most small-scale equipment (e.g., 6 motors + 4 valves + 6 indicators in a small packaging machine). Unlike the IC697MDL750 (32 channels), it avoids wasting 16 unused channels—reducing hardware costs by 30% and making it suitable for 4-slot chassis (e.g., IC697CHS730) that cannot accommodate redundant high-density modules.

Same High Reliability as High-Density Models: While compact, the GE IC697MDL740 retains key protections and diagnostics of the IC697MDL750: per-channel overcurrent protection (3 A trip) prevents damage to \(300+ solenoid valves, and relay contact wear detection alerts to aging components before failure. For a small CNC workshop, this means avoiding unplanned downtime from short-circuited motor relays—saving \)1,000+ in daily production losses.

Dual-Voltage Load Compatibility: With 5–240 V AC/DC switching range and 2 A per-channel capacity, the GE IC697MDL740 drives mixed loads like the IC697MDL750. A standalone HVAC unit, for example, can use the same module to control 24 V DC fan relays (logic power from IC697PWR710F) and 120 V AC valve actuators (external power)—eliminating the need for separate DC-only modules and cutting wiring complexity by 25%.

Space-Efficient for Machine-Side Installations: The GE IC697MDL740’s single-slot design fits in machine-side 4-slot chassis (e.g., IC697CHS730), avoiding the need for a central control cabinet. A small plastic extrusion machine, for instance, can mount the module directly on the machine frame—reducing cable lengths from 10m to 2m and minimizing signal interference (critical for precise valve control).

Typical Application Scenarios

In small CNC lathe workshops, the GE IC697MDL740 (installed in a 4-slot IC697CHS730 chassis) is controlled by IC697CPU770 to drive 6 motor relays (spindle, feed axis), 4 solenoid valves (coolant, chuck), and 6 status indicators. It draws 5V DC logic power from IC697PWR710F and uses external 24 V DC for valves. Per-channel overcurrent protection prevents damage if a motor wire shorts, while LED indicators let operators quickly verify motor activation—reducing troubleshooting time by 50%.

For standalone HVAC units (e.g., office building rooftop units), the GE IC697MDL740 controls 4 fan relays (24 V DC), 3 damper actuators (120 V AC), and 2 alarm lights. It receives control signals from IC697CPU770 (e.g., “start fan” when temperature >25°C) and feeds back relay status via the chassis backplane. Compact size allows installation in the HVAC unit’s built-in control box, avoiding central cabinet costs and long cable runs.

In low-volume packaging machines (e.g., manual-load pouch sealers), the GE IC697MDL740 drives 8 solenoid valves (sealing bars, product pushers) and 4 indicator lights. Controlled by IC697CPU770, it activates valves based on part presence signals (from IC697DIA310 digital input module). Relay contact wear detection alerts to replace aging sealing valve relays during scheduled maintenance—avoiding seal failure and $500+ in wasted packaging material.

Related Model Recommendations

IC697CPU770: Mid-entry Series 90-70 CPU—primary controller for GE IC697MDL740 in small systems (e.g., CNC lathes, HVAC).

IC697PWR710F: Entry-level 10 A power supply—provides 5V DC logic power to GE IC697MDL740 (paired with external load power).

IC697CHS730: 6-slot Series 90-70 chassis—ideal mounting platform for GE IC697MDL740 + IC697CPU770 + IC697DIA310 in small systems.

IC697DIA310: 16-channel digital input module—paired with GE IC697MDL740 to form “input-output loops” (e.g., part presence → valve activation).

IC697MDL750: 32-channel digital output module—upgrade option for GE IC697MDL740 when scaling to 17+ loads (e.g., expanding packaging lines).

IC697BEM731U: Entry-level Ethernet module—enables remote monitoring of GE IC697MDL740 relay status (e.g., HVAC unit diagnostics).

IC697PWR720: Mid-capacity 15 A power supply—upgrade for IC697PWR710F if GE IC697MDL740 drives 12+ high-current loads (e.g., 2 A motors).

GE IC697MDL740

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC697MDL740, power off the Series 90-70 chassis (e.g., IC697CHS730) and verify compatibility with the CPU (IC697CPU770) and power supply (IC697PWR710F). Required tools include an anti-static wristband (prevent ESD damage), torque screwdriver (0.8–1.2 N·m for chassis screws), wire strippers (18–14 AWG for load wires), and a multimeter (to test load power). Ensure the chassis slot is free of dust (critical for machine-side installations).

Installation and wiring: Align GE IC697MDL740 with the chassis slot, push until it latches, and secure with front-panel screws. Connect 5V DC logic power (from chassis backplane) and external load power (24 V DC/120 V AC) to the terminal block. Wire devices to Form C contacts (NO for normal activation, NC for fail-safe)—use shorter cables (≤5m) for machine-side installs to reduce interference. Tighten terminal screws to 0.5 N·m.

Commissioning and maintenance: Power on the chassis and use Proficy Machine Edition to send test signals (e.g., energize Channel 1) — confirm LED lights red and the load activates. Daily maintenance involves checking LEDs (steady red = normal, flickering = contact wear). Every 6 months, inspect relay contacts for corrosion (clean with a dry cloth) and test overcurrent protection with a current injector. Replace GE IC697MDL740 if ≥3 relays show wear or overcurrent trips persist.

Service and Guarantee Commitment

The GE IC697MDL740 comes with a 1-year manufacturer’s warranty—standard for Series 90-70 I/O modules—covering defects in materials (e.g., relays, terminal blocks) and workmanship under industrial use. GE provides 24/7 technical support via phone, email, and online portals, with certified engineers specializing in Series 90-70 small systems available to assist with GE IC697MDL740 installation, wiring troubleshooting, and compatibility checks.

Beyond warranty, GE offers on-site service for GE IC697MDL740, including machine-side commissioning (load testing, interference reduction) and relay inspection. Global service centers stock genuine spare parts (e.g., replacement relays), ensuring expedited replacement (typically 2–3 business days for urgent orders) to minimize downtime in small-scale operations. GE’s quality commitment includes 100% factory testing of each GE IC697MDL740—validating relay switching, protection functions, and channel isolation—to meet the reliability standards of small workshops, HVAC, and packaging industries.