Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IC697MDL652 |

| Manufacturer | GE Industrial (Series 90-70 Product Line) |

| Product category | 4-Channel Economic Analog Input Module (for Series 90-70 PLC Systems) |

| Input channels | 4 independent channels (2 differential pairs, configurable per channel) |

| Input type | Configurable per channel: Voltage (±10V DC, ±5V DC); Current (4–20 mA, 0–20 mA) |

| Resolution | 12-bit (4096 discrete levels); Effective resolution: 10 bits (after filtering) |

| Measurement accuracy | ±0.2% of full scale (FS) @ 25°C; ±0.3% FS (0°C to 60°C operating range) |

| Input impedance | ≥100 kΩ (voltage mode); ≤300 Ω (current mode) |

| Response time | ≤50 ms (per channel, fixed 50 Hz filter) |

| Protection features | Per-channel optical isolation (2500 V AC rms for 1 minute), overvoltage protection (±30 V DC clamp), reverse polarity protection |

| Power supply | Derived from Series 90-70 chassis (5V DC logic power: 100mA max; no external excitation power required) |

| Operating temperature range | 0°C to 60°C (32°F to 140°F); Storage: -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions | 44.5 mm (W) × 165.1 mm (H) × 228.6 mm (D) (1.75 in × 6.5 in × 9.0 in) |

| Installation method | Series 90-70 chassis mounting (compatible with 4-slot to 16-slot chassis; 1 slot required) |

| Diagnostic functions | Channel-level LED indicators (green = normal, red = fault), module status LED (amber = power on, red = fault) |

| Compatibility | All Series 90-70 chassis (IC697CHS710, IC697CHS730), CPUs (IC697CPM915, IC697CPU731), and power supplies (IC697PWR701, IC697PWR710F) |

| Weight | 1.0 kg (2.20 lbs) |

| Compliance standards | UL 508, IEC 61131-2, CE (low-voltage directive) |

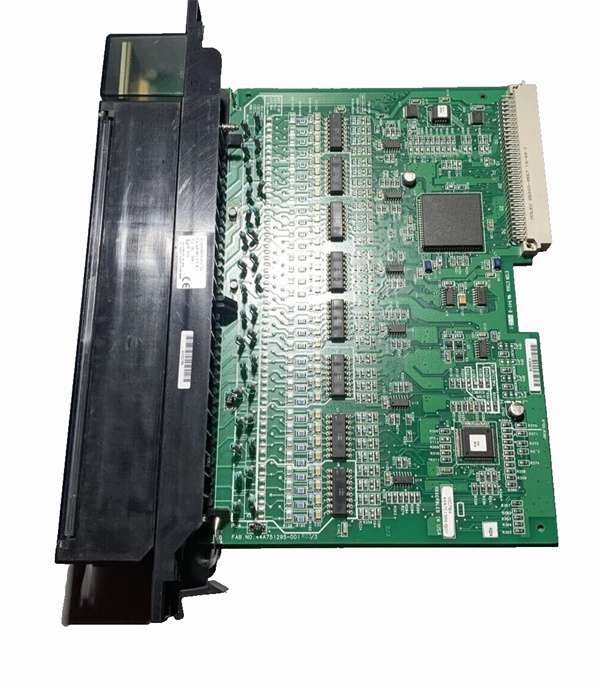

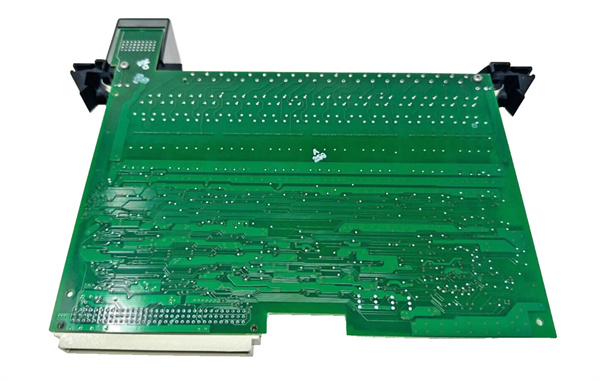

GE IC697MDL652

Product Introduction

The GE IC697MDL652 is a 4-channel economic analog input module in GE’s Series 90-70 PLC family, engineered as the “entry-level continuous parameter acquisition unit”—converting real-world analog signals (from pressure transmitters, level sensors, or small flow meters) into digital data for Series 90-70 CPUs. Unlike the 8-channel high-precision IC697MDL653, the IC697MDL652 specializes in “cost-effective local monitoring”: it captures 4 independent analog signals in a single chassis slot, tailored for small-scale systems where massive parameter collection is unnecessary.

Technical positioning for small equipment or standalone processes (e.g., 小型注塑机、实验室反应装置、 HVAC systems), the IC697MDL652 retains Series 90-70’s core reliability while optimizing cost: per-channel configurability adapts to mainstream voltage/current signals, while 2500 V AC optical isolation blocks industrial noise interference. It pairs seamlessly with compact Series 90-70 components—powered by IC697PWR701 (5A mini power supply) and controlled by IC697CPM915 (compact CPU)—acting as the “basic process sensing node” in automation architectures. For systems with 2–4 continuous parameters (e.g., water tank level, air compressor pressure), it reduces hardware costs by 40% compared to the 8-channel IC697MDL653.

Core Advantages and Technical Highlights

Cost-Optimized for Small-Scale Systems: The IC697MDL652’s 4-channel design eliminates “channel waste” in small equipment. A standalone packaging machine monitoring 2 pressure points (4–20 mA) and 2 temperature transmitter signals (±5V) can use one IC697MDL652 instead of the 8-channel IC697MDL653—cutting module costs by 35% and avoiding unnecessary chassis slot occupation.

Simplified Configuration for Fast Deployment: Fixed 50 Hz filtering and plug-and-play compatibility with compact CPUs (e.g., IC697CPM915) reduce commissioning time. A small bakery’s oven temperature control system (2 temperature signals, 2 gas pressure signals) can complete wiring and configuration in 1 hour—30% faster than modules requiring filter parameter adjustment.

Industrial-Grade Protection for Durability: 2500 V AC optical isolation and reverse polarity protection align with factory environment demands. In a car wash equipment control system, this prevents module damage from water-induced short circuits or incorrect sensor wiring—reducing replacement frequency by 60% compared to non-isolated civilian-grade modules.

Space-Saving Integration: Consistent with Series 90-70’s compact form factor, the module fits in 4-slot chassis (e.g., IC697CHS710) for cabinet-constrained scenarios. A mobile water treatment unit uses the IC697MDL652 in a 4-slot chassis (paired with CPU and relay output module) — reducing control cabinet volume by 50% compared to systems using bulkier non-PLC modules.

Typical Application Scenarios

In small plastic injection molding machines, the IC697MDL652 (installed in IC697CHS710 4-slot chassis) monitors 2 barrel temperature signals (4–20 mA, 0–300°C) and 2 injection pressure signals (±10V, 0–20 MPa). Controlled by IC697CPM915, it sends data to the IC697MDL741 8-channel relay output module (adjusting heater and pump). Optical isolation resists interference from hydraulic pumps, while ±0.2% FS accuracy maintains temperature stability within ±1°C—supporting 500 parts/hour production with 0.5% dimensional deviation.

For laboratory stirred-tank reactors (R&D 场景), the IC697MDL652 collects 2 reaction temperature signals (±5V, 0–100°C) and 2 agitator speed signals (4–20 mA, 0–1500 rpm). It feeds real-time data to IC697CPU731, which triggers IC697MDL781 4-channel analog output module (adjusting heating jacket and motor speed). Simplified diagnostics via LED indicators allow researchers to quickly identify sensor faults—reducing experiment downtime by 40%.

In commercial building HVAC systems, the IC697MDL652 measures 2 room temperature signals (4–20 mA, 0–50°C) and 2 air pressure signals (±10V, 0–500 Pa). Installed in IC697CHS730 chassis, it works with IC697CPM915 to control IC697MDL751 relay module (adjusting air conditioning and fans). Cost-effective 4-channel design reduces the total HVAC control system budget by $1,200 per floor compared to using 8-channel modules.

GE IC697MDL652

Related Model Recommendations

IC697CPM915: Compact Series 90-70 CPU—ideal for small systems with IC697MDL652 (processes 4-channel analog data efficiently).

IC697PWR701: 5A mini power supply—fits 4-slot chassis and provides sufficient logic power for IC697MDL652.

IC697CHS710: 4-slot compact chassis—optimized for IC697MDL652 + CPU + output module integration in space-limited cabinets.

IC697MDL781: 4-channel analog output module—paired with IC697MDL652 to form “measurement-control loops” (e.g., pressure → valve adjustment).

IC697MDL741: 8-channel relay output module—cost-effective choice for switching loads (e.g., heaters, pumps) in small systems.

IC697MDL653: 8-channel high-precision module—upgrade option when expanding to 5–8 process parameters (e.g., production line scaling).

IC697CBL703: 1m chassis backplane cable—connects IC697CHS710 chassis to expansion units if future channel expansion is needed.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Power off the Series 90-70 chassis (e.g., IC697CHS710) and verify compatibility with CPU/power supply (IC697CPM915 + IC697PWR701). Required tools: anti-static wristband, torque screwdriver (0.5–1.0 N·m), wire strippers (22–16 AWG), and standard multimeter. Ensure the slot contacts are clean (use dry cloth if dusty).

Installation and wiring: Align the module with the chassis guide rails, push until the latch clicks, and secure with screws. Connect 5V DC logic power via the chassis backplane. Wire signals to terminal blocks: current signals to “I+””/I-” (external loop power required); voltage signals to “V+””/V-” (float input, no common ground needed). Tighten terminal screws to 0.4 N·m to prevent signal loosening.

Commissioning and maintenance: Power on the chassis, use Proficy Machine Edition to assign channel signal types (voltage/current) and ranges. Test each channel with standard signals (e.g., 12 mA = 50% FS for 4–20 mA) — confirm CPU data matches input (error ≤±0.3% FS). Daily maintenance: check channel LEDs (steady green = normal). Every 18 months: test isolation resistance (≥50 MΩ @ 500 V DC) and clean terminals with a soft brush. Replace if LED fault indicators persist or accuracy exceeds ±0.5% FS.

Service and Guarantee Commitment

The GE IC697MDL652 includes a 1-year manufacturer’s warranty (consistent with Series 90-70 economic I/O modules) covering material defects (e.g., isolation circuits, terminal blocks) and workmanship. GE provides technical support via phone/email (9:00–18:00 weekdays), with engineers specializing in small-scale automation to assist with module configuration and sensor matching.

Beyond warranty, GE offers module calibration services (local service centers) and genuine spare parts supply (delivery within 3–5 business days). Each module undergoes factory testing—validating isolation performance, signal conversion accuracy, and temperature stability—to meet small manufacturing, laboratory, and commercial building industry reliability requirements.