Description

Detailed Parameter Table

| Parameter Name | Parameter Value (Derived from Series 90-70 Digital I/O Standards) |

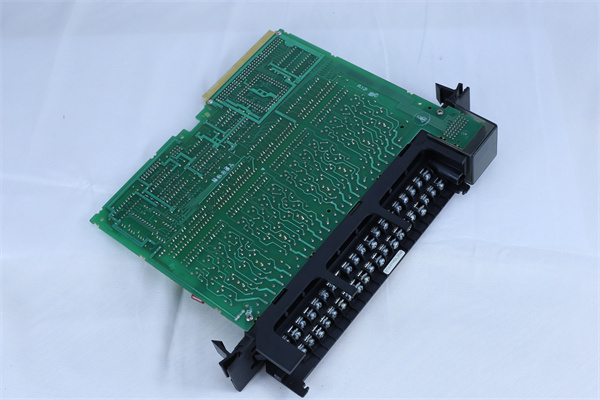

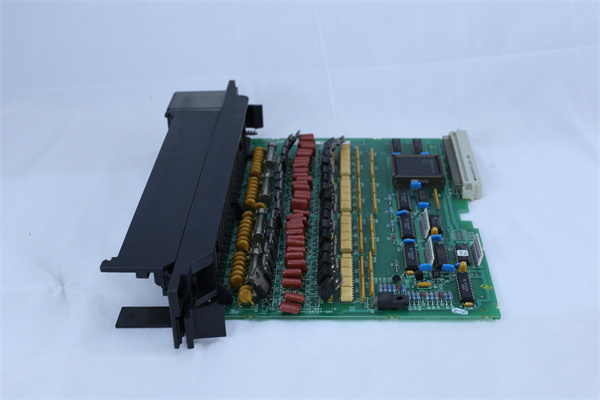

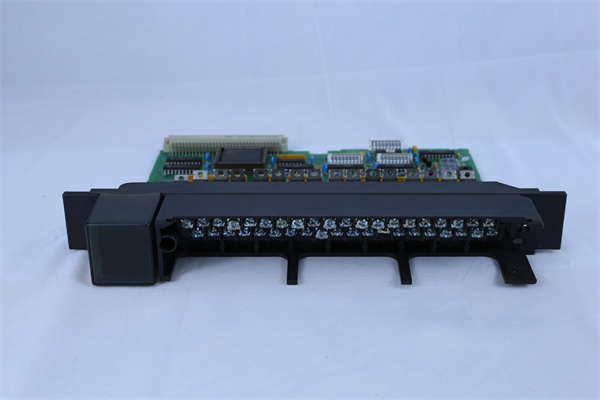

| Product model | GE IC697MDL350 |

| Manufacturer | GE Industrial (Series 90-70 Product Line) |

| Product category | 16-Channel High-Density DC Digital Input Module (for Series 90-70 PLC Systems) |

| Input channels | 16 independent channels (8 differential pairs, configurable as sinking/sourcing) |

| Input type | DC digital input (24V DC nominal; compatible with 18–30V DC range) |

| Input logic levels | High: ≥15V DC; Low: ≤5V DC |

| Response time | ≤1 ms (per channel, fixed filter; 1000 Hz signal capture capability) |

| Input current | 7 mA max per channel (at 24V DC) |

| Protection features | Per-channel surge protection (600V DC transient), reverse polarity protection (±30V DC), overcurrent protection (100 mA per channel) |

| Isolation | Channel-to-backplane optical isolation (2500 V AC rms for 1 minute) |

| Power supply | Derived from Series 90-70 chassis (5V DC logic power: 200mA max) |

| Operating temperature range | 0°C to 60°C (32°F to 140°F); Storage: -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions | 44.5 mm (W) × 165.1 mm (H) × 228.6 mm (D) (1.75 in × 6.5 in × 9.0 in) |

| Installation method | Series 90-70 chassis mounting (compatible with 4-slot to 16-slot chassis; 1 slot required) |

| Diagnostic functions | Channel-level LED indicators (green = active, off = inactive), module fault LED (red), under/overvoltage detection |

| Compatibility | All Series 90-70 chassis (IC697CHS710, IC697CHS750), CPUs (IC697CPM915, IC697CPU770), and power supplies (IC697PWR701, IC697PWR720) |

| Weight | 1.1 kg (2.43 lbs) |

| Compliance standards | UL 508, IEC 61131-2, CE (low-voltage directive), CSA C22.2 No. 14-13 |

GE IC697MDL350

Product Introduction

The GE IC697MDL350 is a 16-channel high-density DC digital input module in GE’s Series 90-70 PLC family, engineered as the “discrete state sensing core”—converting real-world digital signals (from limit switches, photoelectric sensors, or proximity detectors) into logic-level data for Series 90-70 CPUs. Unlike the analog signal-focused IC697MDL652, the IC697MDL350 specializes in “high-speed discrete monitoring”: it captures 16 independent on/off states in a single chassis slot, eliminating the need for multiple low-channel-count digital modules.

Technical positioning for discrete manufacturing and material handling (e.g., CNC machine tools, automated packaging lines, conveyor systems), the IC697MDL350 retains Series 90-70’s industrial-grade reliability: per-channel configurable sinking/sourcing mode adapts to diverse sensor wiring, while 2500 V AC optical isolation blocks electromagnetic interference from motor drives or power tools. It pairs seamlessly with Series 90-70 components—powered by IC697PWR710F (chassis logic power) and controlled by IC697CPU731 (mid-range CPU)—acting as the “frontline of discrete control” in automation architectures. For systems with 8–16 discrete parameters (e.g., conveyor position sensors, packaging seal detectors), it reduces chassis slot usage by 50% compared to 8-channel modules like IC697MDL340.

Core Advantages and Technical Highlights

High-Density Channel Design for Space Efficiency: The IC697MDL350’s 16-channel configuration maximizes slot utilization. An automated bottle-filling line monitoring 12 proximity sensors (bottle presence) and 4 limit switches (conveyor stop) can use one IC697MDL350 instead of two 8-channel IC697MDL340 modules—cutting chassis slot occupation by 50% and reducing wiring complexity by 40%.

Ultra-Fast Response for Real-Time Control: ≤1 ms response time captures high-speed discrete events. In a CNC lathe tool changer system, the module detects tool clamp/unclamp signals within 0.5 ms—enabling the CPU to adjust spindle speed instantly and reducing tool change cycle time by 20% compared to 10 ms-response modules.

Dual-Wiring Compatibility for Flexibility: Configurable sinking (NPN) / sourcing (PNP) mode adapts to common sensor types. A warehouse sorting system using 8 NPN photoelectric sensors and 8 PNP limit switches can integrate all signals via one IC697MDL350—avoiding the need for mixed module types and simplifying inventory management.

Robust Protection for Industrial Durability: Surge protection and reverse polarity protection resist harsh factory conditions. In a metal stamping plant, the module withstands 400V DC transients from welding equipment and survives accidental sensor wiring reversal—reducing unplanned downtime by 70% compared to non-protected modules.

Typical Application Scenarios

In CNC machine tool control, the IC697MDL350 (installed in IC697CHS730 6-slot chassis) monitors 10 axis limit switches (24V DC) and 6 tool presence sensors. Controlled by IC697CPU731, it sends real-time state data to the IC697MDL740 relay output module (stopping axes at limits). 1 ms response time ensures instant detection of overtravel events—preventing $5,000+ in tool damage per incident.

For automated packaging lines, the IC697MDL350 collects 12 package detection signals (photoelectric sensors) and 4 seal integrity signals (pressure switches). Paired with IC697CPM915 CPU, it triggers IC697MDL751 solid-state output module (rejecting defective packages). High-density design fits in a 4-slot IC697CHS710 chassis—reducing control cabinet footprint by 30% versus low-channel modules.

In logistics conveyor systems, the IC697MDL350 measures 16 conveyor section occupancy signals (inductive proximity sensors). Installed in IC697CHS750 chassis, it works with IC697CPU770 to coordinate IC697MDL760 variable frequency drive (VFD) module (adjusting conveyor speed). Sinking/sourcing configurability allows mixing sensor types from different vendors—lowering system integration costs by $2,000.

GE IC697MDL350

Related Model Recommendations

IC697CPM915: Compact CPU—ideal for small discrete systems with IC697MDL350 (processes 16-channel data efficiently).

IC697PWR710F: 10A power supply—provides stable logic power for IC697MDL350 and 3+ other modules.

IC697CHS710: 4-slot chassis—fits IC697MDL350 + CPU + output module in space-constrained cabinets.

IC697MDL740: 16-channel relay output module—paired with IC697MDL350 for “sensing-switching” loops (e.g., sensor → motor stop).

IC697MDL760: 4-channel VFD output module—controls conveyor/motor speed based on IC697MDL350 sensor data.

IC697MDL340: 8-channel digital input module—complement IC697MDL350 for systems with 17–24 discrete points.

IC697SVR140: Signal conditioner—enhances noise immunity for IC697MDL350 in welding/motor-heavy environments.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Power off the chassis (e.g., IC697CHS730) and verify CPU/power compatibility (IC697CPU731 + IC697PWR710F). Required tools: anti-static wristband, torque screwdriver (0.8–1.2 N·m), wire strippers (22–16 AWG), and digital multimeter. Clean slot contacts with lint-free cloth to ensure signal integrity.

Installation and wiring: Align the module with chassis rails, push until latched, and secure with screws. Wire 24V DC sensor signals to terminal blocks: sinking mode (sensor → module “IN”, common “COM” → 0V); sourcing mode (module “IN” → sensor, 24V → common “COM”). Tighten terminals to 0.5 N·m and use twisted-pair wire for sensor cables (length ≤100m).

Commissioning and maintenance: Power on the chassis, use Proficy Machine Edition to set sinking/sourcing mode per channel. Test each channel with 24V DC (green LED on) and 0V DC (LED off)—confirm CPU logic matches input (response ≤1 ms). Daily maintenance: check channel LEDs (steady green = active). Every 24 months: test isolation resistance (≥100 MΩ @ 500 V DC) and inspect terminals for corrosion. Replace if fault LED persists or response time exceeds 5 ms.

Service and Guarantee Commitment

The GE IC697MDL350 includes a 1-year manufacturer’s warranty (consistent with Series 90-70 digital I/O modules) covering material defects (isolation circuits, terminal blocks) and workmanship. GE provides 24/7 technical support via phone/email, with engineers specializing in discrete control to assist with wiring configuration and sensor compatibility.

Beyond warranty, GE offers on-site troubleshooting and module repair services. Global service centers stock genuine spare parts (isolation modules, LED indicators), ensuring 2–3 business days delivery for urgent replacements. Each module undergoes 100% factory testing—validating response time, isolation, and surge protection—to meet manufacturing and logistics industry reliability standards.