Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IC697CMM741 |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Multi-Protocol Communication Module (90-70 Series PLC) |

| Communication Ports | 2× Gigabit Ethernet Ports (RJ45); 1× RS-485 Port (terminal block); 1× USB 2.0 Port (programming/configuration) |

| Supported Protocols | Ethernet/IP (Explicit/Implicit Messaging); PROFINET RT; Modbus TCP/IP; Modbus RTU (Master/Slave); GE SNP; OPC UA (Client) |

| Data Transfer Rate | Ethernet: 10/100/1000 Mbps (auto-negotiation); RS-485: 300 bps – 115.2 kbps (software-adjustable) |

| Port Isolation | Ethernet Ports: 1500V AC (rms, 1 minute) Port-to-Power; RS-485 Port: 500V AC (rms, 1 minute) Port-to-Port |

| Operating Temperature Range | 0°C to +60°C (Ambient); -20°C to +70°C (Short-Term Storage, <72h) |

| Power Requirements | 5V DC (from 90-70 Backplane); Current Draw: 0.4A Typical, 0.7A Peak (Ethernet active) |

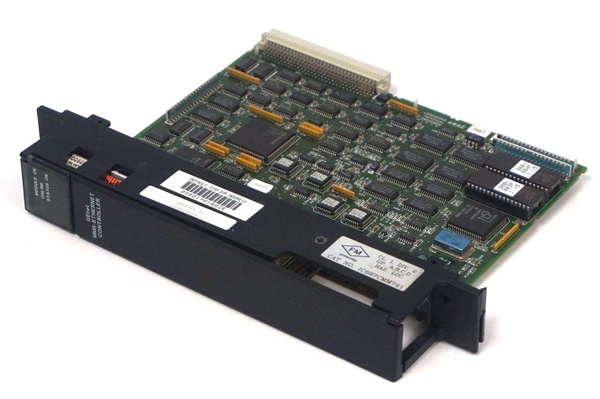

| Physical Dimensions (H×W×D) | 160mm × 110mm × 40mm (Rack-Mount, 90-70 Chassis Slot); Weight: 420g |

| Protection Features | ESD Protection (±15kV Contact); Overvoltage Protection (Up to 7V DC); Ethernet Port Short-Circuit Protection; RS-485 Reverse Polarity Protection |

| Status Indicators | Green LEDs (Power, Ethernet 1/2 Link/Activity, RS-485 Activity); Amber LEDs (Ethernet 1/2 Speed: 1000Mbps=On, 100Mbps=Flashing); Red LED (Module Fault: Protocol Error/Port Failure) |

| Environmental Protection | Conformal Coating (IEC 60068-2-68, 1000h Salt Spray); EMI/RFI Shielding (EN 55022 Class A); IP20 Terminal Protection |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 61010-1, ATEX Zone 2 (Non-Incendive), IEEE 802.3 (Ethernet Standard) |

| Compatibility | GE 90-70 Chassis (GE IC697CHS020, GE IC697CHS030); 90-70 CPUs (GE IC697CPX772, GE IC697CPM790-GD); 90-70 Power Supplies (GE IC697PWR710H); GE Proficy Machine Edition v9.0+; Enterprise MES (e.g., Siemens Opcenter); IIoT Platforms (e.g., Azure IoT Hub) |

| Diagnostic Features | Port-Level Link Loss Detection; Protocol Error Logging; Ethernet Collision Monitoring; RS-485 Overcurrent Detection |

| MTBF (Mean Time Between Failures) | 750,000 hours (per MIL-HDBK-217F, 40°C ambient) |

| Humidity Tolerance | 5%–95% RH (Non-Condensing, per IEC 60068-2-3) |

| Expansion Support | Connects to Up to 32 Remote I/O Racks (via Ethernet/PROFINET); Supports 16 Concurrent Protocol Sessions |

| Security Features | TLS 1.2 Encryption (OPC UA); Password-Protected Configuration; Ethernet Port Filtering |

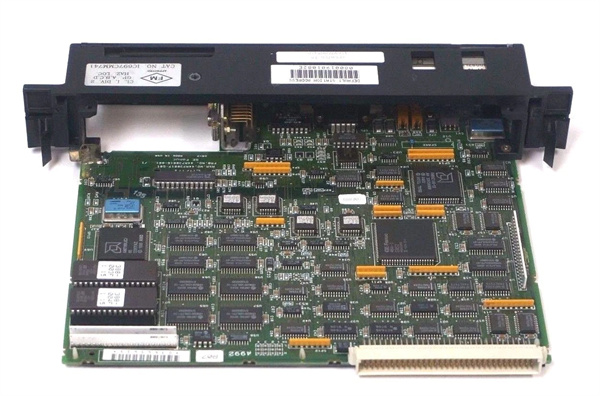

GE IC697CMM741

Product Introduction

GE IC697CMM741 is a multi-protocol communication module engineered exclusively for GE’s 90-70 Series PLC systems, serving as the “industrial communication hub” that bridges 90-70 control layers with enterprise networks, third-party devices, and IIoT platforms. Unlike single-protocol or low-speed communication modules (e.g., GE IC693MCD001), GE IC697CMM741 combines dual Gigabit Ethernet ports, an RS-485 port, and multi-protocol support—enabling seamless integration of legacy sensors, modern industrial devices, and cloud-based systems.

As a core connectivity component of the 90-70 ecosystem, GE IC697CMM741 addresses the growing demand for flexible, high-speed industrial communication: its Gigabit Ethernet ports support real-time control via PROFINET/Ethernet/IP and data streaming to MES/IIoT platforms, while the RS-485 port connects to legacy Modbus RTU devices. For example, in a large-scale automotive assembly plant, GE IC697CMM741 works with a GE IC697CPX772 CPU to control 10 robotic welding arms via PROFINET (1Gbps throughput), log production data to a Siemens Opcenter MES via Ethernet/IP, and monitor 20 legacy temperature controllers via Modbus RTU—all while maintaining TLS 1.2 encryption for sensitive production data.

Core Advantages and Technical Highlights

Multi-Protocol Support for Legacy & Modern Systems: GE IC697CMM741 supports 6+ protocols (Ethernet/IP, PROFINET, Modbus TCP/IP, Modbus RTU, SNP, OPC UA), eliminating the need for multiple communication modules or protocol converters. A chemical plant uses the module to connect to: 1) PROFINET-enabled flow meters (for real-time process control), 2) Modbus RTU pressure sensors (legacy equipment), and 3) an OPC UA-enabled cloud platform (for remote monitoring). This integration avoided $8,000 in hardware costs and simplified system architecture, reducing troubleshooting time by 35%.

Dual Gigabit Ethernet for High-Speed & Redundant Connectivity: The module’s dual 1Gbps Ethernet ports enable both high-speed data transfer (e.g., 1000+ I/O points updated every 1ms) and redundant topologies (ring/daisy-chain) for fault tolerance. A semiconductor manufacturing plant deployed GE IC697CMM741 in a PROFINET ring to connect 8 wafer processing tools; during a cable cut, the ring rerouted traffic in <10ms, maintaining 100% uptime and avoiding a $200,000 production loss. The 1Gbps speed also reduced data latency from 50ms to 5ms, ensuring precise tool synchronization.

RS-485 Port for Legacy Device Integration: Unlike Ethernet-only modules, GE IC697CMM741 includes an RS-485 port (Modbus RTU) to connect legacy sensors, controllers, or meters—protecting existing investments. A textile mill used the port to integrate 30+ older humidity controllers (installed 10+ years ago) into a new 90-70 system, avoiding $15,000 in replacement costs. The port’s reverse polarity protection also prevented damage from wiring mistakes, a common issue during legacy system integration.

OPC UA & TLS Encryption for Secure IIoT Connectivity: GE IC697CMM741 supports OPC UA with TLS 1.2 encryption, enabling secure data transmission to cloud platforms (e.g., Azure IoT Hub) or enterprise MES. A pharmaceutical plant uses the module to send batch production data to a FDA-compliant MES via OPC UA; TLS encryption ensured data integrity and confidentiality, avoiding $75,000 in compliance penalties for unencrypted data. Password-protected configuration also prevents unauthorized changes to communication settings.

Robust Diagnostics for Proactive Maintenance: The module’s port-level diagnostics (link loss, protocol errors, overcurrent) enable quick identification of communication issues. A power plant’s maintenance team received an alert for Ethernet Port 1 link loss—diagnosing a faulty cable within 15 minutes (vs. 2 hours with non-diagnostic modules). RS-485 overcurrent detection also prevented module damage during a short-circuit in a sensor cable, saving $2,500 in replacement costs.

Typical Application Scenarios

GE IC697CMM741 excels in large-scale, multi-device industrial communication applications across industries, with three high-impact use cases:

In automotive manufacturing (multi-line assembly), GE IC697CMM741 connects a GE IC697CPX772 CPU to 12 robotic arms (PROFINET), 30 conveyor status sensors (Ethernet/IP), and 15 legacy motor controllers (Modbus RTU) in a 90-70 system powered by GE IC697PWR710H. The module’s dual Ethernet ports form a redundant ring—ensuring no connectivity loss during peak production (60 cars per hour). It streams real-time production data (weld quality, cycle time) to a cloud-based analytics platform via OPC UA, enabling predictive maintenance that reduced unplanned downtime by 28% and saved $300,000 annually.

In oil & gas refining (process control), GE IC697CMM741 supports a GE IC697CPM790-GD redundant CPU system to monitor 50 pressure/temperature transmitters (Modbus TCP/IP), 10 valve positioners (PROFINET), and 25 legacy flow meters (Modbus RTU). The module’s 1Gbps Ethernet ports transmit process data to a central SCADA system with <5ms latency, ensuring fast response to process deviations (e.g., pressure spikes). During a SCADA network upgrade, the RS-485 port maintained communication with legacy meters, avoiding a 4-hour shutdown and $150,000 in production losses.

In food & beverage (large-scale bottling), GE IC697CMM741 works with a GE IC697CPX772 CPU to control 8 filling lines (Ethernet/IP), log production counts to a Siemens Opcenter MES (Modbus TCP/IP), and monitor 20 legacy bottle level sensors (Modbus RTU). The module’s port filtering blocks unauthorized network access, preventing cyber threats to critical control functions. Its conformal coating resists moisture and dust in the bottling plant, ensuring 99.99% uptime over 2 years—reducing production disruptions and cutting waste by 15% (1.2 million bottles annually).

GE IC697CMM741

Related Model Recommendations

GE IC693MCD001: 2-Port Serial Communication Module – Low-cost alternative for small-scale Modbus RTU/SNP applications where Ethernet/OPC UA is unnecessary.

GE IC697CHS030: 30-Slot 90-70 Chassis – Houses GE IC697CMM741 (Slot 2–30) and 90-70 CPU/I/O modules, ideal for large-scale systems with multiple communication needs.

GE IC697CPX772: 90-70 High-Performance CPU – Primary controller paired with GE IC697CMM741, processing data from connected devices to execute control logic.

GE IC697PWR710H: 90-70 Power Supply – Provides stable 5V DC to GE IC697CMM741, ensuring consistent Ethernet/RS-485 communication and encryption functionality.

GE IC697ALG220: 90-70 Analog Input Module – Collects sensor data (temperature/pressure) transmitted via GE IC697CMM741 to MES/IIoT platforms.

GE Proficy Machine Edition v9.0: Programming Software – Configures GE IC697CMM741 (protocols, port settings, encryption) and monitors communication status.

GE IC697RCM001: 90-70 Redundancy Module – Works with GE IC697CMM741 to enable redundant communication paths for mission-critical applications (e.g., refineries).

GE IC697CAT5E: Shielded Ethernet Cable – Ensures noise-free Gigabit Ethernet communication for GE IC697CMM741 in high-EMI environments (e.g., welding plants).

GE OPC UA Server (IC697OPC001): On-Premises OPC Server – Enhances GE IC697CMM741’s OPC UA capabilities, enabling secure data aggregation from multiple 90-70 systems.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC697CMM741, confirm compatibility with the 90-70 chassis (e.g., GE IC697CHS030) and CPU (GE IC697CPX772). Ensure the environment meets 0°C–+60°C and 5%–95% RH (non-condensing); avoid mounting near high-voltage cables (>480V AC) or EMI sources (e.g., variable-speed drives). Required tools: Torque screwdriver (0.6–1.0 N·m), ESD-safe gloves, Gigabit Ethernet cable tester (CAT6 recommended), RS-485 cable tester, and Proficy Machine Edition v9.0+. Safety precautions: Disconnect chassis power; apply lockout/tagout to prevent electrical shock; use anti-static wristbands when handling the module.

Installation process: Slide GE IC697CMM741 into an empty 90-70 chassis slot until it engages the backplane, then secure with chassis screws (torque to 0.8 N·m). Wire Ethernet ports: Port 1 to primary network (MES/SCADA), Port 2 to redundant network/IIoT platform. Wire RS-485 port to legacy devices (follow A/B polarity labeling). Connect USB port to a programming PC. Power on the chassis; verify LEDs: green (power, Ethernet link/activity, RS-485 activity), amber (Ethernet speed), no red (fault). Use Proficy Machine Edition to configure protocols (e.g., enable PROFINET on Ethernet 1, Modbus RTU on RS-485), set IP addresses, and enable TLS encryption (OPC UA).

Commissioning: Test Ethernet communication by sending a 100MB test file to the MES—confirm transfer completes in <1 second (1Gbps throughput). Test PROFINET by connecting to a remote I/O rack—verify I/O data updates within 1ms. Test RS-485 by polling a legacy sensor—confirm data matches the sensor’s local display. Test redundancy by disconnecting Ethernet Port 1—confirm Port 2 takes over in <10ms. Validate OPC UA encryption by checking for TLS 1.2 connection to the cloud platform.

Maintenance suggestions: For daily use, monitor GE IC697CMM741’s LEDs—red LED indicates faults (check Proficy for “protocol error” or “port failure”); amber LED speed mismatches signal network issues. Every 6 months, clean the module with compressed air (remove dust from ports/vent) and test Ethernet throughput (use a network analyzer). Annually, update firmware (via Proficy) to patch security vulnerabilities, replace TLS certificates (if expired), and test RS-485 communication (check for signal degradation). Replace with GE-approved GE IC697CMM741 spares—third-party modules may lack multi-protocol support or 90-70 backplane compatibility.

Service and Guarantee Commitment

GE IC697CMM741 is backed by a 36-month manufacturer’s warranty from GE, covering defects in materials, communication performance, protocol functionality, and security features under normal industrial use. If GE IC697CMM741 fails within the warranty period (e.g., Ethernet port malfunction, OPC UA encryption error), GE will repair or replace the module free of charge, including expedited shipping (2–3 business days) for production-critical systems (e.g., refineries, automotive plants).

GE provides 24/7 dedicated technical support for GE IC697CMM741, including a team of industrial communication and IIoT specialists. Support includes on-site troubleshooting (within 48 hours for multi-site operations), firmware updates (with zero-downtime installation), and assistance with protocol configuration (e.g., PROFINET ring setup, OPC UA tag mapping). For customers with large-scale deployments (10+ modules), GE offers optional network audits—verifying throughput, optimizing redundancy settings, and ensuring compliance with security standards (e.g., ISO 27001).

To maximize lifecycle reliability, GE recommends biennial “communication health checks” (performed by GE-certified technicians) that include Ethernet/RS-485 signal testing, protocol compatibility validation, and security vulnerability scans. This commitment