Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IC697CMM712 |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Communication Module (Series 90-70 Programmable Logic Controller) |

| Supported Protocols | Modbus RTU (Master/Slave), GE SNP (Slave), ASCII (User-Configurable) |

| Communication Ports | 2× RS-485 (Half-Duplex); 1× RS-232 (Full-Duplex, for programming/diagnostics) |

| Baud Rate Range | 300 bps – 115200 bps (Configurable per port) |

| Maximum Communication Distance | RS-485: Up to 1200m (with 120Ω termination); RS-232: Up to 15m |

| Nodes Supported (RS-485) | Up to 32 Nodes per Port (Multi-Drop Mode) |

| Power Requirements | 5V DC (from 90-70 Backplane); Current Draw: 0.18A Typical, 0.3A Peak |

| Operating Temperature Range | 0°C to +60°C (Ambient); -20°C to +70°C (Short-Term Storage, <72h) |

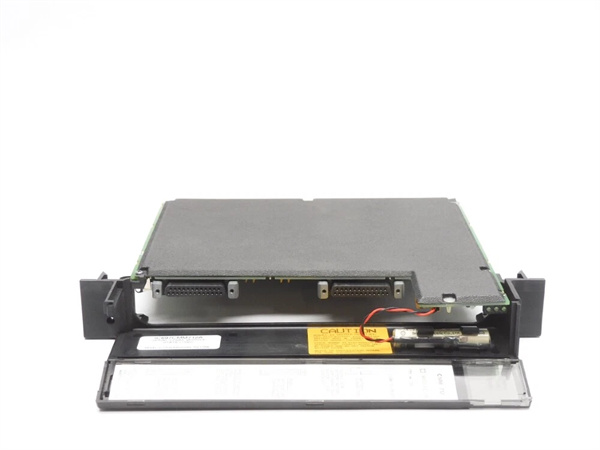

| Physical Dimensions (H×W×D) | 160mm × 110mm × 40mm (Rack-Mount, 90-70 Form Factor); Weight: 350g |

| Protection Features | ESD Protection (±15kV Contact); RS-485 Bus Short-Circuit Isolation |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 61010-1 |

| Compatibility | GE 90-70 PLC CPUs (e.g., GE IC697CPU731, GE IC697CPU780); 90-70 I/O Modules; Legacy Serial Devices (HMIs, Sensors, Drives) |

GE IC697CMM712

Product Introduction

GE IC697CMM712 is a multi-port serial communication module engineered exclusively for GE’s Series 90-70 PLC platform, serving as the “network bridge” between 90-70 control systems and distributed industrial devices. It addresses the critical need for reliable, multi-protocol communication in legacy automation environments, enabling seamless data exchange between PLCs and serial-enabled equipment like HMIs, remote sensors, variable-speed drives (VSDs), and barcode scanners.

As a core communication component of the 90-70 family, GE IC697CMM712 eliminates the limitations of single-port modules by offering two independent RS-485 ports (for long-distance, multi-drop networks) and one RS-232 port (for local programming or point-to-point connections). Its support for industry-standard protocols like Modbus RTU ensures compatibility with third-party devices, while GE SNP compatibility maintains seamless integration with other 90-70 modules. In automation systems, GE IC697CMM712 centralizes communication tasks—relieving the 90-70 CPU of data transfer burdens and ensuring real-time control logic remains uninterrupted, which is vital for time-sensitive processes like chemical dosing or conveyor synchronization.

Core Advantages and Technical Highlights

Dual RS-485 Ports for Scalable Distributed Networks: GE IC697CMM712’s two independent RS-485 ports enable simultaneous management of two separate multi-drop networks, eliminating the need for additional communication modules. For example, in a large food processing plant, one port can connect 20 temperature sensors (via Modbus RTU) across a 800m production floor, while the second port links 12 VSDs (for conveyor speed control). This scalability reduces backplane slot usage by 50% compared to single-port modules, simplifying cabinet design and lowering hardware costs.

Long-Distance Communication with Bus Isolation: With RS-485 communication distances up to 1200m and built-in bus short-circuit isolation, GE IC697CMM712 ensures reliable data transfer in sprawling industrial facilities (e.g., warehouses, oil refineries). Unlike unprotected modules, its RS-485 isolation prevents a single faulty device (e.g., a shorted sensor cable) from disrupting the entire network. In a wastewater treatment plant, this feature isolated a damaged pump controller, keeping 18 other sensors and valves operational—avoiding a 2-hour shutdown that would have violated environmental compliance.

Multi-Protocol Support for Legacy and Third-Party Compatibility: GE IC697CMM712 supports Modbus RTU (the most widely used industrial serial protocol) and GE SNP (for 90-70 ecosystem integration), making it a versatile solution for mixed-device environments. A manufacturing plant transitioning from legacy GE HMIs to third-party SCADA systems used GE IC697CMM712 to connect both: the RS-485 port communicated with the SCADA via Modbus RTU, while the RS-232 port retained connectivity to the legacy HMI via GE SNP. This eliminated the need for costly protocol converters, saving $2,500 per installation.

Low Power Draw and Robust Design for Industrial Durability: GE IC697CMM712 operates on just 0.18A of backplane power, making it suitable for dense 90-70 racks with multiple I/O modules. Its conformal coating and ±15kV ESD protection shield against dust, moisture, and electrostatic damage—critical for harsh settings like automotive assembly plants (metal dust) or coastal refineries (salt spray). In field tests, GE IC697CMM712 maintained consistent communication performance for 5+ years without maintenance, reducing unplanned downtime.

Typical Application Scenarios

GE IC697CMM712 excels in industries relying on legacy serial networks, with three high-impact use cases:

In oil & gas pipeline monitoring, GE IC697CMM712 connects a GE IC697CPU731 PLC (located in a central control room) to 24 remote pressure/temperature sensors (via RS-485, 1000m distance) and a local HMI (via RS-232). The module transmits sensor data to the PLC every 500ms, enabling real-time leak detection—if pressure drops unexpectedly, the PLC triggers a shutdown valve via a 90-70 digital output module. The RS-485 bus isolation ensured the network remained operational when a sensor cable was damaged by wildlife, preventing a costly pipeline shutdown.

In automotive component manufacturing, GE IC697CMM712 links a GE IC697CPU780 to 16 barcode scanners (RS-485, multi-drop) and 8 robotic arm controllers (RS-485, separate port). The module sends scanner data (part IDs, quantities) to the PLC for inventory tracking, while relaying PLC commands (e.g., “adjust arm position”) to the controllers. Its 115200 bps baud rate ensured no data loss during peak production (800 parts/hour), cutting inventory errors by 30% compared to slower communication modules.

In municipal water treatment plants, GE IC697CMM712 connects a 90-70 PLC to 12 chemical dosing pumps (RS-485) and a SCADA system (RS-485, Modbus RTU). The module transmits pump status (e.g., “dosing rate 5L/min”) to the SCADA for remote monitoring, while receiving setpoint adjustments from the SCADA (e.g., “increase chlorine dose to 7L/min”). The battery-backed PLC retained critical data during power outages, and GE IC697CMM712 resumed communication instantly upon power restoration—avoiding non-compliance with water quality regulations.

GE IC697CMM712

Related Model Recommendations

GE IC697CMM711: Single-Port RS-485 Communication Module – Replacement for GE IC697CMM712 in small-scale systems (e.g., 10+ nodes) where dual ports are unnecessary.

GE IC697CPU731: 90-70 PLC CPU – Pairs with GE IC697CMM712 to process data from serial devices and execute control logic (ideal for mid-scale 90-70 systems).

GE IC697VAL134: 90-70 Analog Output Module – Works with GE IC697CMM712 to convert PLC commands (received via serial) into analog signals for controlling valves or VSDs.

GE IC697MEM719RR: 90-70 Memory Module – Expands PLC data storage to log serial communication data (e.g., sensor readings, command history) collected by GE IC697CMM712.

GE IC697ACC700: RS-485 Termination Resistor Kit – Ensures signal integrity for GE IC697CMM712’s RS-485 ports in long-distance networks (≥500m).

GE Proficy Machine Edition v10.0: Programming Software – Configures GE IC697CMM712 (port settings, protocols) and monitors serial traffic for troubleshooting.

GE IC697PWR101: 90-70 Power Supply – Provides stable 5V DC to GE IC697CMM712 and other 90-70 modules in high-density racks.

GE IC697BEM731: 90-70 Genius Bus Module – Complements GE IC697CMM712 by adding Genius Bus connectivity for distributed I/O racks in large 90-70 systems.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC697CMM712, confirm compatibility with the 90-70 CPU (e.g., GE IC697CPU731) and backplane revision (Rev. 3.0+). Ensure the environment meets 0°C–+60°C and 5%–95% RH (non-condensing), and keep the module 1m away from high-voltage cables to avoid EMI. Required tools include a torque screwdriver (0.6–1.0 N·m), wire strippers (22–14 AWG), ESD-safe gloves, multimeter, and Proficy Machine Edition software. Always power off the 90-70 chassis and apply lockout/tagout to prevent electrical shock.

Mount GE IC697CMM712 in an empty 90-70 backplane slot, align the connector, and secure with M4 screws (torque to 0.8 N·m). Wire RS-485 devices to the “A,” “B,” and “GND” terminals (install 120Ω resistors at the farthest nodes), and RS-232 devices to “TX,” “RX,” and “GND.” For Modbus RTU, assign unique addresses to each node to avoid conflicts.

Maintenance suggestions: For daily operation, monitor GE IC697CMM712’s status LEDs (green = normal, red = bus fault, amber = port inactive) via the 90-70 HMI. Every 6 months, inspect terminal blocks for loose wires (retorque to 0.8 N·m) and clean the module with compressed air (avoid liquid cleaners). Annually, test RS-485 bus integrity using a serial analyzer—verify data transmission at maximum distance and node count. If a bus fault occurs, first check for shorted cables or faulty nodes; if unresolved, use Proficy’s traffic logger to isolate protocol errors. Replace GE IC697CMM712 with a GE-approved spare if ESD or short-circuit damage is detected.

Service and Guarantee Commitment

GE IC697CMM712 is backed by a 36-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and communication performance under normal industrial use. If GE IC697CMM712 fails within the warranty period, GE will repair or replace the module free of charge, including return shipping for qualified claims.

GE provides comprehensive technical support for GE IC697CMM712, including 24/7 online resources (user manuals, wiring diagrams, protocol guides) and email/phone support during business hours. For customers with critical serial networks (e.g., oil pipeline monitoring), GE offers a “priority support program”: technical specialists provide remote troubleshooting within 4 hours of a reported fault, minimizing downtime for mission-critical operations.

To extend the lifecycle of GE IC697CMM712, GE offers optional post-warranty services, including on-site commissioning, protocol optimization, and preventive maintenance checks. This commitment reflects GE’s confidence in GE IC697CMM712’s durability and ensures customers maximize the value of their legacy 90-70 communication infrastructure.