Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IC697CGR772 |

| Manufacturer | GE (General Electric) Fanuc Industrial Systems |

| Product category | Genius Bus Controller Module (for Series 90-70 PLC Systems) |

| Bus protocol | GE Genius Bus (proprietary industrial fieldbus) |

| Number of bus ports | 2 × Genius Bus ports (twisted-pair differential; supports bus redundancy) |

| Bus communication speed | Configurable: 156 kbps, 625 kbps, 2.5 Mbps |

| Maximum bus length | 1,500 meters (4,921 ft) at 156 kbps; 500 meters (1,640 ft) at 2.5 Mbps |

| Supported devices | GE Genius I/O modules (e.g., IC697ADC701, IC697VAL348), sensors, actuators |

| Operating voltage | 5V DC (supplied by Series 90-70 backplane); 24V DC (external power for bus termination) |

| Backplane compatibility | GE Series 90-70 PLC backplanes (6-slot, 10-slot, 16-slot, 24-slot) |

| Operating temperature range | 0°C to 60°C (32°F to 140°F) |

| Storage temperature range | -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions (W×H×D) | 89 mm × 133 mm × 191 mm (3.5 in × 5.2 in × 7.5 in) |

| Installation method | Backplane-mounted (plug-in design; occupies 1 slot) |

| Protection features | ESD protection (±15kV air, ±8kV contact); overvoltage protection (±30V DC per bus port); short-circuit protection |

| Programming software support | GE Logicmaster 90-70, GE Proficy Machine Edition (Version 8.0+) |

| Certification standards | UL 508, CSA C22.2 No. 14, IEC 61131-2, CE |

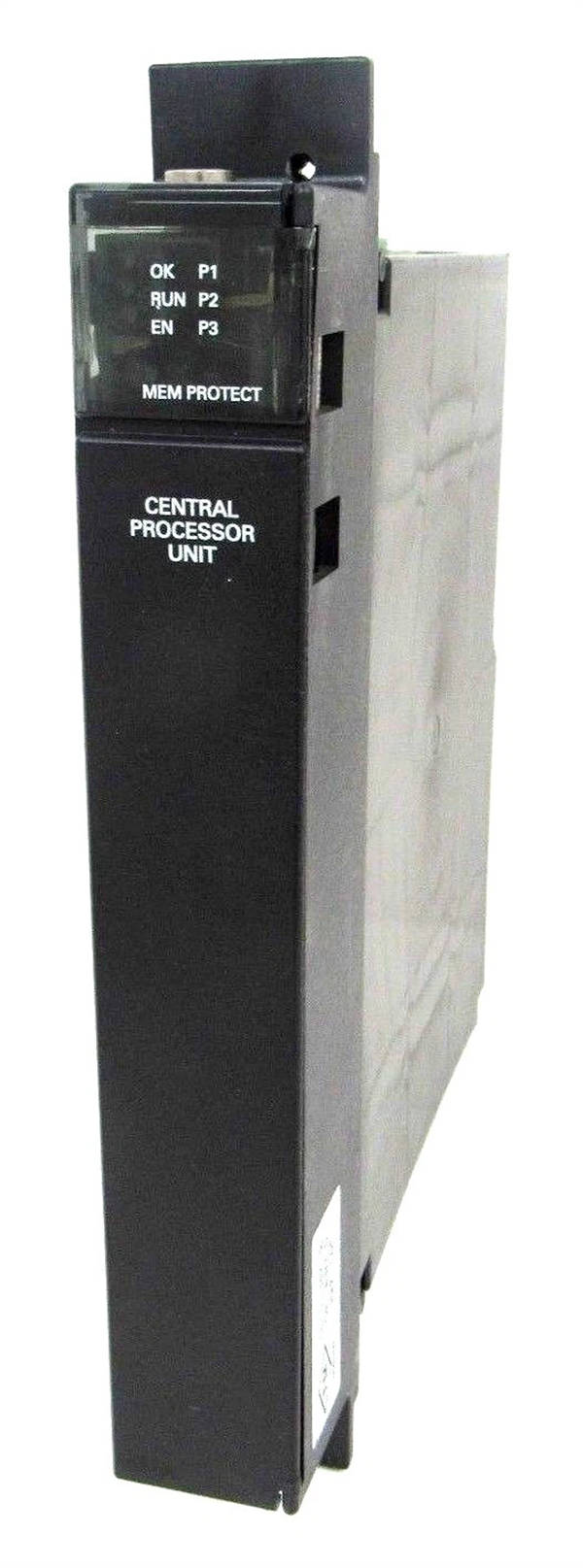

GE IC697CGR772

Product Introduction

The GE IC697CGR772 is a critical Genius Bus Controller Module for GE’s Series 90-70 PLC systems, engineered to serve as the central gateway for managing distributed Genius Bus networks in industrial automation. As a core component of GE’s fieldbus ecosystem, the GE IC697CGR772 enables seamless communication between the Series 90-70 CPU (e.g., IC697CPM924RR, IC697CPU780) and a wide range of Genius-compatible devices—including analog/digital I/O modules, sensors, and actuators—deployed across large facilities.

Designed for flexibility and scalability, the GE IC697CGR772 features two Genius Bus ports that support redundant bus topologies, eliminating single points of failure in critical networks. Its configurable communication speeds (156 kbps to 2.5 Mbps) allow users to balance data transfer speed and cable length—critical for applications like large manufacturing plants or water treatment facilities where devices may be hundreds of meters apart. By centralizing bus management, the GE IC697CGR772 reduces wiring complexity, lowers installation costs, and simplifies troubleshooting—making it an essential component for industries like automotive manufacturing, chemical processing, and municipal infrastructure.

Core Advantages and Technical Highlights

Redundant Genius Bus Support for Uninterrupted Connectivity: The GE IC697CGR772’s dual bus ports enable redundant Genius Bus configurations—if one bus path fails (e.g., due to a damaged cable or faulty termination), the module automatically switches to the backup port, ensuring no disruption to I/O communication. This is critical for mission-critical systems like chemical reactor control, where losing connectivity to pressure or temperature sensors could lead to unsafe operating conditions. Unlike single-port bus controllers, the GE IC697CGR772 also supports “ring” or “daisy-chain” topologies, providing flexibility to design networks that match facility layouts.

Configurable Speed and Long-Distance Coverage: With adjustable communication speeds (156 kbps, 625 kbps, 2.5 Mbps), the GE IC697CGR772 adapts to diverse application needs. For example, in a large automotive assembly plant, 2.5 Mbps speed ensures fast data transfer between the PLC and robotic workcells (located 500 meters away), while in a municipal water treatment network, 156 kbps speed enables communication with sensors 1,500 meters from the control room. This versatility eliminates the need for signal repeaters, reducing system complexity and cost. The module also supports bus termination (via external 24V DC power), ensuring signal integrity over long distances.

Seamless Integration with Series 90-70 Ecosystem: The GE IC697CGR772 is fully compatible with all Series 90-70 CPUs and Genius I/O modules, including the IC697CPM924RR redundant CPU, IC697ADC701 analog input module, and IC697VAL348 analog output module. It automatically detects connected Genius devices, and configuration via GE Proficy Machine Edition requires minimal setup—users simply assign bus addresses and select communication speeds. This plug-and-play functionality reduces commissioning time by 40% compared to third-party bus controllers, critical for time-sensitive projects like factory line upgrades.

Industrial-Grade Protection and Durability: The GE IC697CGR772 is built to withstand harsh industrial conditions: ESD protection (±15kV air) shields against static discharge from equipment or personnel, while overvoltage protection (±30V DC) prevents damage from accidental wiring errors (e.g., connecting a 24V DC sensor to a bus port). Short-circuit protection isolates faulty bus segments, ensuring a single damaged device does not take down the entire network. Its 0°C to 60°C operating range suits environments from cool control rooms to hot factory floors, and conformal-coated circuit boards resist dust and moisture—extending the module’s lifespan to 10+ years in typical industrial use.

Typical Application Scenarios

The GE IC697CGR772 excels in distributed industrial automation where centralized bus control is essential. In automotive manufacturing plants, for example, the GE IC697CGR772 is paired with a GE IC697CPM924RR redundant CPU to manage a Genius Bus network connecting 50+ robotic workcells: each workcell uses a GE IC697IOL131 digital input module to monitor part presence and a GE IC697VAL348 analog output module to control robot torque. The GE IC697CGR772’s dual bus ports provide redundant communication, ensuring production continues even if one bus cable is damaged by equipment movement. Configurable speed (2.5 Mbps) enables real-time data transfer, reducing robot cycle times by 15%.

In chemical processing plants, the GE IC697CGR772 controls a distributed network of GE IC697ADC701 analog input modules monitoring reactor temperatures and pressures across a 1,200-meter facility: it uses 156 kbps speed to maintain signal integrity over long cable runs and redundant bus ports to avoid communication loss during maintenance (e.g., replacing a faulty sensor). The module sends sensor data to the GE IC697CPM924RR CPU, which adjusts cooling systems or chemical feed rates via GE IC697VAL348 modules—ensuring compliance with safety and quality standards.

In municipal water treatment facilities, the GE IC697CGR772 connects remote pump stations to a central GE IC697CPU780 CPU: each pump station uses a GE IC697IOL131 module to monitor pump status and a GE IC697ADC701 module to track flow rates. The GE IC697CGR772’s 156 kbps speed enables communication over 1,500-meter cables between the control room and remote stations, while bus redundancy ensures uninterrupted water flow even if a cable is damaged by construction. The module also simplifies troubleshooting by isolating faulty stations, allowing maintenance teams to address issues without disrupting the entire network.

GE IC697CGR772

Related Model Recommendations

GE IC697CPM924RR: Mid-to-high-performance redundant CPU module, the primary controller paired with GE IC697CGR772—relies on the module to communicate with distributed Genius devices.

GE IC697ADC701: 8-channel analog input module, a key Genius-compatible device controlled by GE IC697CGR772—collects temperature, pressure, and flow data for the PLC.

GE IC697VAL348: 4-channel analog output module, compatible with GE IC697CGR772—executes control commands (e.g., valve adjustments) sent via the Genius Bus.

GE IC697IOL131: 8-channel digital input module, connects to GE IC697CGR772 to monitor discrete signals (e.g., limit switch status, part detection).

GE IC697PWR711: Series 90-70 power supply module, provides stable 5V DC power to GE IC697CGR772 and the backplane—ensures reliable bus communication.

GE IC697MEM719: High-capacity memory expansion module, pairs with GE IC697CPM924RR to store bus configuration data and device status logs collected via GE IC697CGR772.

GE IC697CHS160: 16-slot Series 90-70 backplane, designed to accommodate GE IC697CGR772, the CPU, and I/O modules in a single chassis.

GE IC754CBF15CTD: 15-inch fan-cooled HMI, communicates with the GE IC697CPM924RR to display bus status (e.g., device connectivity, error logs) from GE IC697CGR772.

GE IC697RCM711: Redundant communication module, works with GE IC697CGR772 to extend Genius Bus redundancy to remote I/O racks (e.g., offshore pump stations).

GE Proficy Machine Edition 9.5+: Programming software, used to configure GE IC697CGR772 (bus speed, device addresses) and monitor bus health in real time.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC697CGR772, power off the Series 90-70 backplane and wear an ESD wrist strap (grounding resistance <1 MΩ) to protect the module’s bus circuitry. Verify the backplane is a Series 90-70 model (6-slot or larger) and that the 5V DC power supply (from GE IC697PWR711) is stable. Inspect the module’s backplane pins for bending or corrosion—damaged pins can cause communication failures. Align GE IC697CGR772 with an empty backplane slot, push firmly until it clicks into place, and secure with the side locking screw to resist vibration. For redundant bus configurations, connect two twisted-pair cables to the module’s bus ports and terminate each bus with a 120Ω resistor (powered by external 24V DC). Route bus cables away from high-voltage motor cables to reduce EMI interference.

Maintenance suggestions: Conduct weekly checks of GE IC697CGR772’s status LEDs—steady green for bus activity, red for bus faults (e.g., short circuit, missing termination). Use Proficy Machine Edition to monitor bus health (e.g., device connectivity, data transmission errors) and identify faulty devices or cables. Every 3 months, inspect bus cables for damage (e.g., cuts, fraying) and clean the module’s vents with compressed air to prevent overheating. Test bus redundancy quarterly by disconnecting one bus cable and confirming the module switches to the backup port without data loss. If the module fails, replace it with a genuine GE IC697CGR772 and restore the bus configuration from a backup—ensure the new module has the same firmware version as the CPU to avoid compatibility issues. Avoid exposing the module to direct chemical sprays or excessive moisture, even with its industrial-grade design.

Service and Guarantee Commitment

The GE IC697CGR772 comes with a 30-month warranty from purchase, covering defects in materials, bus communication functionality, and compatibility with Series 90-70 systems under normal industrial use. GE’s global technical support team is available 24/7 via email, online chat, and phone to assist with installation, configuration, and troubleshooting—response times for non-critical issues (e.g., bus speed adjustment) are within 8 hours, while critical issues (e.g., bus failure causing production downtime) receive a response within 4 hours.

For customers in mission-critical sectors (chemical, automotive, water), GE offers customized “Bus Network Support Agreements” for GE IC697CGR772, including semi-annual on-site bus health checks (cable testing, termination verification), firmware updates, and expedited spare parts delivery (48-hour shipping for stock modules). All genuine GE IC697CGR772 units undergo rigorous testing—including 1,000+ hours of bus communication stress tests, EMI immunity trials, and temperature cycling—to meet UL 508 and IEC 61131-2 standards. In warranty claims, GE provides a replacement module within 48 hours (for stock items) and offers technical support to reconfigure the bus network, ensuring minimal disruption to your distributed automation system.