Description

Detailed Parameter Table

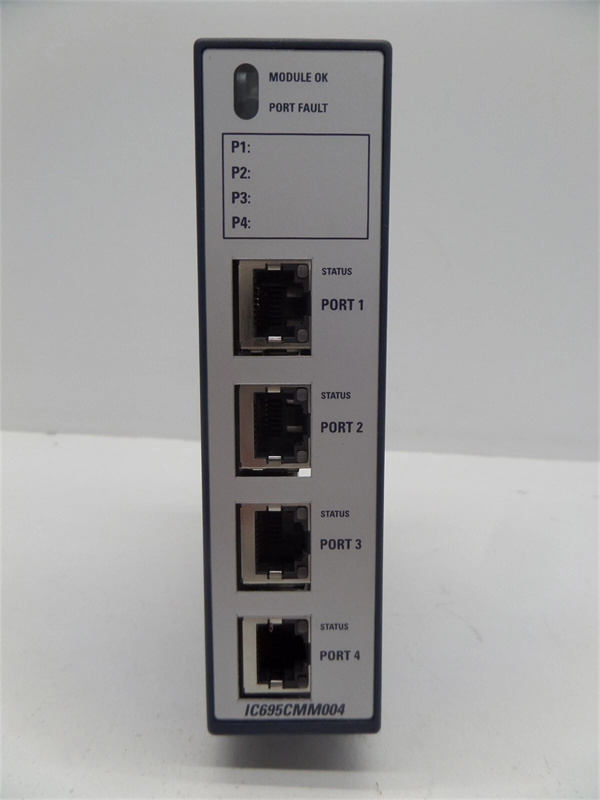

| Parameter Name | Parameter Value |

| Product model | GE IC695DEM004 |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Mixed Digital I/O Module (RX3i Series Programmable Logic Controller) |

| I/O Configuration | 16 Digital Input Channels + 8 Digital Output Channels (Independent) |

| Input Voltage Range | 24V DC (Sinking/Sourcing Configurable) |

| Output Voltage Range | 24V DC (Sinking; Max 0.5A per Channel, 4A Total Per Module) |

| Input Current | 7mA Typical per Channel (24V DC) |

| Input Response Time | ≤1ms (for 0→1 and 1→0 Transitions) |

| Output Protection | Short-Circuit Protection (Current-Limited to 0.6A per Channel) |

| Status Indication | LED per Channel (Green = Active Input/Output; Red = Output Short-Circuit) |

| Isolation | Channel-to-Channel: 500V AC (rms); Channel-to-Backplane: 1500V AC (rms) |

| Communication Interface | RX3i Backplane (3.125 Gbps High-Speed Bus) |

| Power Requirements | 5V DC (from RX3i Chassis Backplane); Current Draw: 0.3A Typical, 0.5A Peak |

| Operating Temperature Range | -20°C to +70°C (Ambient); -40°C to +85°C (Short-Term Storage, <72h) |

| Physical Dimensions (H×W×D) | 85mm × 110mm × 30mm (Rack-Mount, RX3i Series Form Factor); Weight: 210g |

| Protection Features | ESD Protection (±15kV Contact); Overvoltage Protection (Up to 36V DC Input/Output) |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 61010-1, ATEX Zone 2 (Non-Incendive) |

| Compatibility | GE RX3i PLC Chassis (e.g., GE IC695CHS017, GE IC695CHS024); RX3i CPUs (GE IC695CPU340); Proficy Machine Edition v9.0+ |

GE IC695DEM004

Product Introduction

GE IC695DEM004 is a versatile mixed digital I/O module engineered exclusively for GE’s RX3i Series PLC systems, serving as a “dual-purpose control interface” that combines 16 digital inputs and 8 digital outputs in a single chassis slot. It addresses the common industrial need for compact, integrated I/O solutions—eliminating the need to install separate input and output modules, thus optimizing backplane space and reducing wiring complexity in mid-scale automation projects.

As a flexible core component of the RX3i ecosystem, GE IC695DEM004 stands out for its balanced I/O ratio, making it ideal for applications where monitoring and control go hand-in-hand (e.g., “detect a part → trigger a valve”). Its inputs support both sinking (NPN) and sourcing (PNP) 24V DC devices (e.g., proximity sensors, limit switches), while its outputs drive low-power actuators (e.g., small relays, indicator lights) with built-in short-circuit protection. In automation systems, GE IC695DEM004 feeds real-time input data to RX3i CPUs (e.g., GE IC695CPU340) and executes output commands—for example, detecting a full conveyor via a photoeye (input) and stopping the conveyor via a motor relay (output)—ensuring seamless coordination between sensing and actuation.

Core Advantages and Technical Highlights

Mixed I/O Design for Space Optimization: GE IC695DEM004 integrates 16 inputs and 8 outputs into one RX3i slot, reducing backplane usage by 50% compared to using separate 16-input (e.g., GE IC200NDR001-24 truncated) and 8-output modules. A small packaging machine builder, for instance, uses GE IC695DEM004 to monitor 12 sensors (e.g., part presence, door interlocks) and control 6 actuators (e.g., fill valves, conveyor motors)—all with one module. This cuts chassis slot needs from 2 to 1, enabling a smaller control cabinet and lowering overall system costs by 20%.

Dual Input Configuration for Sensor Versatility: Unlike fixed-input modules, GE IC695DEM004’s 16 inputs support both sinking (NPN) and sourcing (PNP) 24V DC devices via simple wiring adjustments. A food processing plant integrating legacy NPN temperature switches and new PNP photoeyes uses GE IC695DEM004 to connect all sensors without module swaps. This eliminates the need to stock two input module types, reducing inventory costs and simplifying maintenance—technicians only need to learn one module’s wiring logic.

Built-In Output Short-Circuit Protection: GE IC695DEM004’s outputs include current-limiting short-circuit protection (0.6A per channel), preventing module damage from accidental wiring errors or faulty actuators. A warehouse using GE IC695DEM004 to control pallet stop solenoids experienced a shorted solenoid cable— the module limited current to 0.6A, avoiding burnout and continuing to operate other outputs. This protection has prevented 3 costly module replacements in the plant’s first year, saving $1,800.

Fast Input Response + Reliable Outputs for Real-Time Control: With ≤1ms input response time, GE IC695DEM004 captures fast signals (e.g., high-speed encoder pulses) critical for precision tasks. In an automotive component tester, the module detects a misaligned part via a proximity sensor (input) in 0.9ms and triggers a reject cylinder (output) in <2ms—ensuring defective parts are removed before reaching the next station. Its outputs also maintain stable 24V DC performance across -20°C to +70°C, avoiding actuation delays in cold warehouse or hot factory environments.

Typical Application Scenarios

GE IC695DEM004 excels in applications requiring paired sensing and actuation, with three high-impact use cases:

In small-scale manufacturing (e.g., electronic component assembly), GE IC695DEM004 connects to a GE IC695CPU340 RX3i CPU to control a pick-and-place machine. Its 16 inputs monitor 10 part sensors (e.g., “component loaded”), 4 safety interlocks (e.g., “machine door closed”), and 2 position encoders. Its 8 outputs control 4 robotic grippers, 2 conveyor motors, and 2 indicator lights. When a sensor detects a missing component (input), the CPU uses GE IC695DEM004 to stop the gripper (output) and trigger an alarm light—preventing empty picks and reducing component waste by 15%.

In commercial refrigeration (e.g., grocery store coolers), GE IC695DEM004 monitors 8 temperature sensors (inputs, via 24V DC transmitters) and 4 door ajar switches, while controlling 4 fan relays and 2 defrost valves (outputs). If a cooler door is left open (input), the module activates an alarm light (output) and increases fan speed (output) to maintain temperature. Its -20°C operating range ensures reliable performance in walk-in freezers, and its isolation prevents electrical noise from cooler compressors from causing false inputs.

In water treatment (e.g., small municipal plants), GE IC695DEM004 monitors 10 flow sensors (inputs) and 6 level switches (e.g., “tank full”), while controlling 5 pump relays and 3 valve solenoids (outputs). When a level switch detects a full tank (input), the module stops the fill pump (output) and opens a transfer valve (output)—preventing overflows. Its short-circuit protection safeguards against pump motor shorts, a common issue in wet environments, ensuring continuous treatment operations.

GE IC695DEM004

Related Model Recommendations

GE IC200NDR001-24: 24-Channel Digital Input Module – Complements GE IC695DEM004 for applications needing additional inputs (e.g., 20+ sensors) beyond its 16-input capacity.

GE IC200NDD001-24: 24-Channel Digital Output Module – Pairs with GE IC695DEM004 to add more outputs (e.g., 10+ actuators) for larger-scale control tasks.

GE IC695CHS024: 2-Slot RX3i Chassis – Houses GE IC695DEM004 and a RX3i CPU (e.g., GE IC695CPU340) for small automation systems (e.g., single machines).

GE IC695CPU340: RX3i High-Performance CPU – Processes I/O data from GE IC695DEM004 and executes control logic (e.g., interlock sequences, alarm triggers).

GE IC200ALG326: 8-Channel Analog Input Module – Adds analog monitoring (e.g., temperature, pressure) to RX3i systems using GE IC695DEM004 for digital control.

GE Proficy Machine Edition v9.0: Programming Software – Configures GE IC695DEM004 (input type, output current limits) and monitors channel status in real time.

GE IC695PWR120: 120W RX3i Power Supply – Provides stable 5V DC to GE IC695DEM004 and other RX3i modules, ensuring reliable output performance.

GE IC695STK001RX3I: RX3i Stacking Kit – Expands RX3i systems to support multiple GE IC695DEM004 modules for large I/O counts (e.g., 32 inputs + 16 outputs).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing GE IC695DEM004, confirm compatibility with the RX3i chassis (e.g., GE IC695CHS024) and CPU (e.g., GE IC695CPU340). Ensure the environment meets -20°C to +70°C and 5%–95% RH (non-condensing), and keep the module 0.5m away from high-voltage cables (e.g., motor power lines) to minimize EMI. Required tools include a torque screwdriver (0.4–0.6 N·m), wire strippers (22–18 AWG), ESD-safe gloves, multimeter, and Proficy Machine Edition v9.0+. Always power off the RX3i chassis and apply lockout/tagout to prevent electrical shock.

Mount GE IC695DEM004 in an empty RX3i chassis slot, align the backplane connector, and secure with the chassis’ locking lever. Wire inputs: for sinking (NPN), connect device common to 24V DC +; for sourcing (PNP), connect device common to 24V DC -. Wire outputs: connect actuators to output terminals and 24V DC common (ensure total load ≤4A). Verify wiring with a multimeter—check for 24V DC at inputs (when active) and confirm outputs switch voltage on/off per CPU command.

Maintenance suggestions: For daily operation, monitor GE IC695DEM004’s LEDs (green = normal, red = output short) and Proficy Machine Edition status (check for “output overload” faults). Every 6 months, inspect terminal blocks for loose wires (retorque to 0.5 N·m) and clean the module with compressed air (avoid liquid cleaners) to remove dust or debris. Annually, test input response time with a signal generator (verify ≤1ms transitions) and check output short-circuit protection by simulating a short (ensure current limits to 0.6A). If an output fails, first test the actuator and wiring; if unresolved, replace GE IC695DEM004 with a GE-approved spare to maintain system reliability.

Service and Guarantee Commitment

GE IC695DEM004 is backed by a 36-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and I/O performance (e.g., input response time, output protection) under normal industrial use. If GE IC695DEM004 fails within the warranty period—for example, due to a faulty output circuit or defective isolation—GE will repair or replace the module free of charge, including return shipping for qualified claims.

GE provides comprehensive technical support for GE IC695DEM004, including 24/7 online resources (wiring diagrams, configuration guides, troubleshooting flowcharts) and email/phone support during business hours. For customers with critical RX3i systems (e.g., food processing lines, refrigeration networks), GE offers a “priority support program”: technical specialists provide remote guidance within 4 hours of a reported fault, minimizing downtime for I/O-dependent operations.

To extend the lifecycle of GE IC695DEM004, GE offers optional post-warranty services, including on-site commissioning (verifying I/O wiring and protection features) and preventive maintenance checks (testing input/output performance). This commitment reflects GE’s confidence in GE IC695DEM004’s durability and ensures customers maximize the value of their RX3i mixed digital I/O infrastructure.