Description

DS3800NTSC1A1A: Product Overview

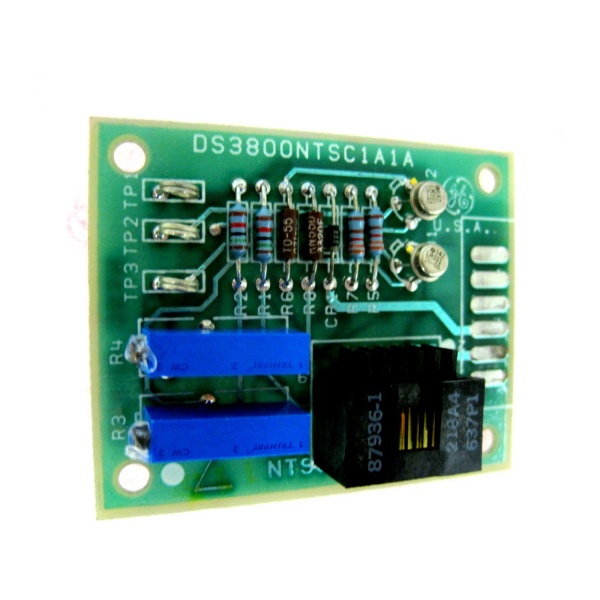

The board serves as a dedicated temperature signal conditioning and monitoring module within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this specialized interface card processes low-level signals from temperature sensors dispersed throughout the turbine envelope—measuring exhaust gas temperatures, bearing metal conditions, steam path temperatures, and auxiliary system thermal states. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring that critical thermal protection functions remain available through redundant measurement paths.

As a temperature sensor card, the unit provides the precise analog signal conditioning necessary to convert millivolt-level thermocouple outputs or resistance temperature detector (RTD) signals into standardized digital data for the Mark IV control processors. The board’s circuitry includes cold junction compensation for thermocouple inputs, linearization algorithms for non-linear sensor outputs, and high-resolution analog-to-digital conversion to detect subtle temperature changes that could indicate developing machinery faults. Integrated diagnostic capabilities monitor sensor integrity, detecting open circuits, short circuits, and out-of-range conditions that could compromise protection schemes.

The board features robust construction utilizing high-quality components rated for the thermal and vibrational stresses encountered in turbine control enclosures. The design supports continuous monitoring of multiple temperature points simultaneously, providing real-time data for control algorithms, protective trip functions, and operational trending. LED indicators provide local status indication for sensor health and board operational state.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture allows temperature monitoring to execute autonomously while maintaining deterministic synchronization with protective trip logic and control algorithms.

DS3800NTSC1A1A: Technical Specifications

-

Model Number: DS3800NTSC1A1A

-

Manufacturer: General Electric

-

Product Type: Temperature Sensor Conditioning Card

-

Series: GE Speedtronic Mark IV

-

Sensor Inputs: Thermocouple (Types J, K, T, E) and/or RTD (100Ω Pt, 120Ω Ni) configurations

-

Cold Junction Compensation: Integrated CJC circuitry for thermocouple accuracy

-

Measurement Accuracy: High-precision signal conditioning (±0.5°C typical)

-

A/D Conversion: 12-bit to 16-bit resolution for temperature trending

-

Input Protection: Overvoltage protection and line filtering for signal integrity

-

Diagnostic Features: Open/short sensor detection, out-of-range alarming

-

Status Indication: LED indicators for sensor status and board health

-

Backplane Interface: High-density modular connector (AMD 218A4553-1 compatible)

-

Operating Temperature: -35°C to +65°C (ambient, control cabinet)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Physical Construction: Rigid PCB with temperature-stable passive components

-

Mounting: Standard Mark IV rack slot with retention hardware

DS3800NTSC1A1A

Part 4: Core Features & Customer Value

High-Precision Temperature Monitoring for Equipment Protection: The board provides the signal conditioning precision necessary to detect temperature deviations that could indicate bearing distress, blade path abnormalities, or cooling system failures. By converting low-level sensor signals with high-resolution A/D conversion and linearization, the board ensures that control algorithms receive accurate data for thermal limiting and protection calculations. For reliability engineers, this precision enables predictive maintenance strategies—identifying bearing degradation through subtle temperature rises before catastrophic failure occurs.

Comprehensive Sensor Diagnostics: Integrated diagnostic circuitry continuously monitors sensor loop integrity, detecting open thermocouples (indicating broken wires), shorted sensors, or readings outside physical limits. These diagnostics generate alarms that alert operators to sensor failures before protection functions are lost. For maintenance teams, this reduces troubleshooting time by pinpointing whether temperature anomalies represent actual machinery conditions or measurement system faults, eliminating unnecessary inspections during critical outages.

Robust Signal Conditioning for Industrial Environments: The board employs temperature-stable components and cold junction compensation circuits that maintain calibration accuracy despite variations in control cabinet ambient temperatures. This stability is critical for exhaust gas temperature monitoring, where control decisions depend on consistent measurement of high-temperature differentials. The construction resists the vibrational stresses and thermal cycling inherent in turbine enclosures, ensuring that calibration drift remains minimal over years of continuous operation.

Seamless Integration with Protection Systems: The conditioned temperature signals feed directly into the Mark IV’s voting and protection logic, enabling coordinated protective actions such as exhaust gas temperature-spread tripping, bearing overtemperature protection, and steam temperature limiting. The board’s deterministic response ensures that temperature-based protective functions execute within specified timeframes, supporting Safety Integrity Level (SIL) requirements for turbine protection systems. For plant operators, this integration provides confidence that thermal protection remains available even during single-channel maintenance activities.

Hot-Swappable Design for Maintenance Efficiency: The board supports replacement within the Mark IV TMR architecture, allowing technicians to service temperature monitoring circuits without turbine shutdown. The standardized form factor and connector system facilitate rapid exchange during urgent repairs, while retention hardware ensures reliable operation between maintenance intervals. Given the obsolete status of the Mark IV platform, this maintainability is essential for ensuring long-term availability of critical temperature monitoring functions.

Part 5: Typical Applications

Gas Turbine Exhaust Gas Temperature Monitoring:

The DS3800NTSC1E1A is deployed in GE Frame 5, 6, 7, and 9 gas turbines to monitor exhaust gas thermocouples arranged in radial arrays at the turbine exhaust. In these applications, the board conditions millivolt signals from Type K or Type J thermocouples measuring gas path temperatures exceeding 1,000°F (537°C). The high-precision conditioning enables calculation of temperature spreads between combustion cans—an indication of combustion imbalance or fuel nozzle distress. The board’s diagnostic capabilities detect failed thermocouples, allowing the control system to exclude bad sensors from averaging calculations and prevent nuisance trips while maintaining protection against overtemperature conditions.

The DS3800NTSC1E1A is deployed in GE Frame 5, 6, 7, and 9 gas turbines to monitor exhaust gas thermocouples arranged in radial arrays at the turbine exhaust. In these applications, the board conditions millivolt signals from Type K or Type J thermocouples measuring gas path temperatures exceeding 1,000°F (537°C). The high-precision conditioning enables calculation of temperature spreads between combustion cans—an indication of combustion imbalance or fuel nozzle distress. The board’s diagnostic capabilities detect failed thermocouples, allowing the control system to exclude bad sensors from averaging calculations and prevent nuisance trips while maintaining protection against overtemperature conditions.

Turbine Bearing Temperature Protection:

In both gas and steam turbine applications, the board monitors bearing metal temperatures using RTD sensors embedded in bearing shells. The conditioned signals support bearing overtemperature protection algorithms that trip the turbine before journal seizure or white metal wiping occurs. The board’s ability to detect subtle temperature changes (±1°C resolution) enables early warning of bearing distress caused by oil contamination, misalignment, or lubrication system degradation. This early detection allows operators to schedule maintenance during planned outages rather than experiencing forced outages from catastrophic bearing failures.

In both gas and steam turbine applications, the board monitors bearing metal temperatures using RTD sensors embedded in bearing shells. The conditioned signals support bearing overtemperature protection algorithms that trip the turbine before journal seizure or white metal wiping occurs. The board’s ability to detect subtle temperature changes (±1°C resolution) enables early warning of bearing distress caused by oil contamination, misalignment, or lubrication system degradation. This early detection allows operators to schedule maintenance during planned outages rather than experiencing forced outages from catastrophic bearing failures.

Steam Turbine Steam Path Monitoring:

In steam turbine installations within power plants and petrochemical facilities, the board conditions signals from thermocouples monitoring steam temperatures at turbine inlets, extraction points, and exhaust stages. These measurements support thermal efficiency calculations, steam temperature control, and protection against excessive thermal stresses that could damage turbine rotors or casings. The board’s cold junction compensation ensures accuracy in measuring the high-temperature differentials between superheated steam and ambient reference conditions critical for turbine lifecycle management.

In steam turbine installations within power plants and petrochemical facilities, the board conditions signals from thermocouples monitoring steam temperatures at turbine inlets, extraction points, and exhaust stages. These measurements support thermal efficiency calculations, steam temperature control, and protection against excessive thermal stresses that could damage turbine rotors or casings. The board’s cold junction compensation ensures accuracy in measuring the high-temperature differentials between superheated steam and ambient reference conditions critical for turbine lifecycle management.

Aeroderivative Turbine Package Monitoring:

For LM6000 and LM2500 units, the board monitors package temperatures including compartment ventilation, lube oil systems, and fuel forwarding equipment. The compact design fits within the limited control enclosure space typical of aeroderivative installations while providing the same precision as larger frame turbine applications. The board monitors temperatures in high-vibration environments near the turbine power package, ensuring reliable operation despite the higher-frequency vibrations characteristic of aeroderivative units.

For LM6000 and LM2500 units, the board monitors package temperatures including compartment ventilation, lube oil systems, and fuel forwarding equipment. The compact design fits within the limited control enclosure space typical of aeroderivative installations while providing the same precision as larger frame turbine applications. The board monitors temperatures in high-vibration environments near the turbine power package, ensuring reliable operation despite the higher-frequency vibrations characteristic of aeroderivative units.

Generator and Auxiliary Equipment Monitoring:

The board extends temperature monitoring to generator stator windings, hydrogen coolers, and auxiliary motor bearings. These measurements support generator thermal protection and cooling system control, ensuring that the generator operates within design temperature limits during peak load conditions or cooling system degradation. The board’s diagnostic capabilities detect sensor failures in these critical systems, ensuring that loss of temperature monitoring generates appropriate alarms and does not leave equipment unprotected.

The board extends temperature monitoring to generator stator windings, hydrogen coolers, and auxiliary motor bearings. These measurements support generator thermal protection and cooling system control, ensuring that the generator operates within design temperature limits during peak load conditions or cooling system degradation. The board’s diagnostic capabilities detect sensor failures in these critical systems, ensuring that loss of temperature monitoring generates appropriate alarms and does not leave equipment unprotected.