Description

DS3800NSWA1A1B: Product Overview

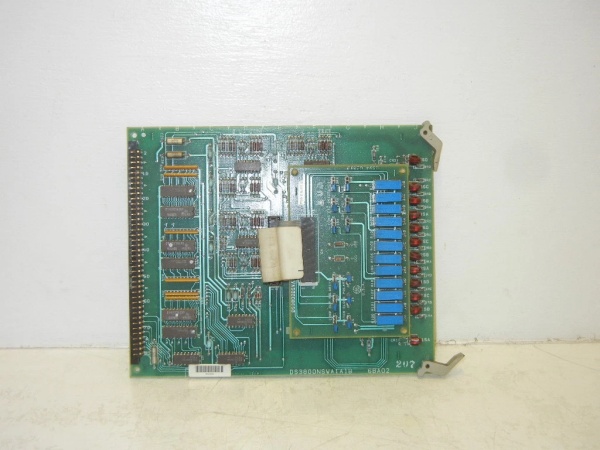

The board serves as a network switching and node service interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this unit functions as a critical communication hub that manages data routing between the central microprocessor complex, distributed I/O modules, and external communication networks. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring that data packets are correctly routed and that communication integrity is maintained across redundant processing paths.

As a network switch board, the unit handles the VME backplane bus arbitration and data switching functions necessary for deterministic communication in real-time control applications. It manages the flow of data between the CPU modules, memory boards, and peripheral I/O cards, ensuring that high-priority protection signals receive appropriate bus access while maintaining throughput for routine monitoring data. The board’s logic provides the electrical interface and protocol management required for reliable communication over the Mark IV’s proprietary backplane architecture.

The board features diagnostic LEDs that provide immediate visual confirmation of network activity, bus arbitration status, and fault conditions without requiring diagnostic software connections. Socketed EPROM modules contain the network configuration data, addressing maps, and communication protocols specific to the turbine installation. The board interfaces with the high-density modular backplane connector system, ensuring reliable signal integrity while retention levers provide mechanical security in high-vibration environments.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture requires deterministic data exchange between modules, and this switching board provides the infrastructure necessary to maintain microsecond-level coordination between control functions.

GE DS3800NSWA1A1B

DS3800NSWA1A1B: Technical Specifications

-

Model Number: DS3800NSWA1A1B

-

Manufacturer: General Electric

-

Product Type: Network Switch / Node Service Interface Board

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Function: VME backplane bus switching and data routing

-

Logic Circuits: TTL/CMOS integrated circuits for bus arbitration and switching

-

Memory: EPROM sockets for network configuration and addressing firmware

-

Bus Interface: VME-compatible backplane switching logic

-

Status Indication: Diagnostic LEDs for network activity and fault detection

-

Backplane Connection: High-density modular connector (AMD 218A4553-1 compatible)

-

Data Rate: High-speed switching for real-time control applications

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Mounting: Standard Mark IV rack slot with integrated retention levers

-

Power Supply: Derived from Mark IV rack backplane (+5 VDC logic)

Part 4: Core Features & Customer Value

Deterministic Data Routing for Real-Time Control: The board manages the VME backplane bus arbitration to ensure that critical protection signals and control commands receive priority access while maintaining data flow for monitoring functions. This deterministic switching is essential for turbine protection systems where microsecond delays in data exchange could impact safety. For control system engineers, this ensures that the distributed architecture maintains the hard real-time performance necessary for overspeed protection and vibration monitoring.

Modular Communication Infrastructure: By providing standardized network switching functions, the board enables the flexible configuration of Mark IV systems with varying complements of I/O cards, memory modules, and processor boards. This modularity allows system integrators to customize the control architecture for specific turbine applications—ranging from simple single-shaft units to complex multi-shaft combined cycle plants—without redesigning the communication backbone.

Comprehensive Diagnostic Visibility: Integrated diagnostic LEDs provide immediate indication of bus activity, arbitration conflicts, and communication errors. During commissioning or troubleshooting, technicians can verify that data is flowing between the CPU and I/O modules, identify backplane communication faults, and confirm that the switching logic is properly arbitrating bus access. This visibility reduces mean time to repair by isolating communication failures to the board level before investigating field wiring or sensor issues.

Robust Industrial Design for Continuous Operation: The board utilizes industrial-grade logic components and passive devices rated for extended temperature operation and high-vibration environments typical of turbine control enclosures. The retention levers ensure reliable backplane engagement despite mechanical stresses, while the modular connector system facilitates hot-swappable replacement in TMR configurations. This construction ensures continuous availability of the communication infrastructure over decades of service life.

Flexible Configuration for Diverse Applications: EPROM-based firmware allows the same hardware to support different backplane configurations, addressing schemes, and communication protocols required for various turbine models. This configurability reduces spare parts inventory requirements for facilities with mixed turbine fleets, as the board can be adapted to specific applications through firmware rather than requiring model-specific hardware variants.

GE DS3800NSWA1A1B

Part 5: Typical Applications

Gas Turbine Control System Communication Backbone:

The DS3800NSWA1A1B is deployed in GE Frame 5, 6, 7, and 9 gas turbine installations to manage data exchange between the central microprocessor boards and distributed I/O modules. In these applications, the board arbitrates access to the VME backplane for temperature monitoring cards, servo valve drivers, and discrete I/O modules. It ensures that high-priority exhaust gas temperature data and vibration signals receive timely access while managing routine data exchanges for auxiliary system monitoring.

The DS3800NSWA1A1B is deployed in GE Frame 5, 6, 7, and 9 gas turbine installations to manage data exchange between the central microprocessor boards and distributed I/O modules. In these applications, the board arbitrates access to the VME backplane for temperature monitoring cards, servo valve drivers, and discrete I/O modules. It ensures that high-priority exhaust gas temperature data and vibration signals receive timely access while managing routine data exchanges for auxiliary system monitoring.

Steam Turbine Retrofit Communication Integration:

In steam turbine modernization projects where Mark IV controls replace legacy analog or early digital systems, this board provides the communication infrastructure that interfaces new microprocessor controls with existing field wiring through distributed I/O. It manages the addressing and data routing for hybrid configurations where modern control processors must communicate with legacy signal conditioning equipment, facilitating phased upgrades without complete system replacement.

In steam turbine modernization projects where Mark IV controls replace legacy analog or early digital systems, this board provides the communication infrastructure that interfaces new microprocessor controls with existing field wiring through distributed I/O. It manages the addressing and data routing for hybrid configurations where modern control processors must communicate with legacy signal conditioning equipment, facilitating phased upgrades without complete system replacement.

Aeroderivative Compact System Networking:

For LM6000 and LM2500 units with limited control enclosure space, the board manages the high-density communication requirements of compact, highly integrated control systems. It handles the rapid data exchange necessary for the fast-acting control sequences of aeroderivative turbines, ensuring that communication latency does not compromise the quick-start capabilities or load-following performance required for peaking applications.

For LM6000 and LM2500 units with limited control enclosure space, the board manages the high-density communication requirements of compact, highly integrated control systems. It handles the rapid data exchange necessary for the fast-acting control sequences of aeroderivative turbines, ensuring that communication latency does not compromise the quick-start capabilities or load-following performance required for peaking applications.

Distributed I/O Network Management:

In large combined cycle plants with extensive I/O requirements spread across multiple control cabinets, the board manages the network switching that extends the Mark IV backplane architecture beyond the main rack. It interfaces with remote I/O concentrators and distributed processing nodes, ensuring that data from turbine package auxiliaries, heat recovery steam generators, and balance-of-plant equipment reaches the central processors with deterministic timing.

In large combined cycle plants with extensive I/O requirements spread across multiple control cabinets, the board manages the network switching that extends the Mark IV backplane architecture beyond the main rack. It interfaces with remote I/O concentrators and distributed processing nodes, ensuring that data from turbine package auxiliaries, heat recovery steam generators, and balance-of-plant equipment reaches the central processors with deterministic timing.

Safety Instrumented System (SIS) Communication:

Within the Mark IV’s integrated protection architecture, this board manages the communication pathways for safety-critical data exchanges between protective input modules, voting logic processors, and trip output circuits. It ensures that safety-related data receives appropriate priority in backplane arbitration, supporting the deterministic response requirements for SIL-rated turbine protection systems and ensuring that protective functions remain coordinated across redundant channels.

Within the Mark IV’s integrated protection architecture, this board manages the communication pathways for safety-critical data exchanges between protective input modules, voting logic processors, and trip output circuits. It ensures that safety-related data receives appropriate priority in backplane arbitration, supporting the deterministic response requirements for SIL-rated turbine protection systems and ensuring that protective functions remain coordinated across redundant channels.