Description

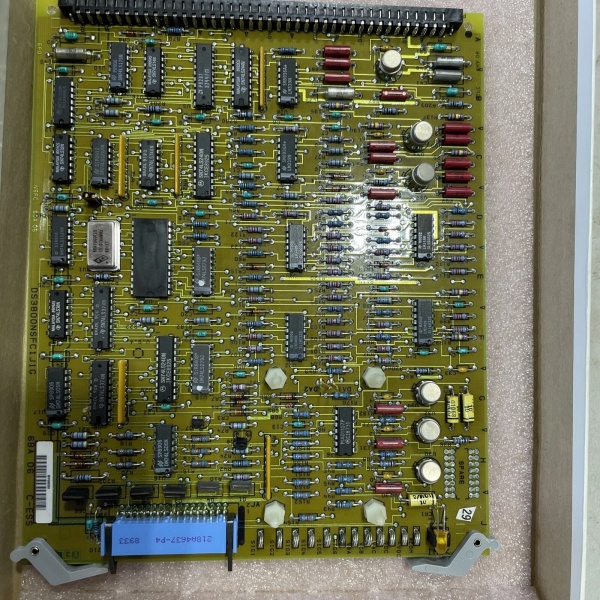

DS3800NSFC1J1G: Product Overview

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as an intelligent field switch interface with predictive diagnostics capabilities. It monitors up to 16 dry-contact or 24 Vdc field switches, performs real-time health assessment of switch contacts and wiring, predicts impending failures based on contact resistance trends and bounce patterns, and reports both status and health metrics to the main CPU over the NDIA data bus. The “NSFC” designation indicates switch/field/control functionality with intelligence, while the J1G revision represents the latest generation with machine-learning-based predictive algorithms and enhanced diagnostic reporting.

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as an intelligent field switch interface with predictive diagnostics capabilities. It monitors up to 16 dry-contact or 24 Vdc field switches, performs real-time health assessment of switch contacts and wiring, predicts impending failures based on contact resistance trends and bounce patterns, and reports both status and health metrics to the main CPU over the NDIA data bus. The “NSFC” designation indicates switch/field/control functionality with intelligence, while the J1G revision represents the latest generation with machine-learning-based predictive algorithms and enhanced diagnostic reporting.

The epoxy-sealed construction makes this a line-replaceable module—internal faults require complete card swap rather than field repair. The module hot-swaps when the rack is powered down, and its low profile allows adjacent-slot population without additional cooling. As part of the DS3800 family, it benefits from the Mark IV platform’s deterministic 2 ms control interval and extensive installed base in power generation applications.

DS3800NSFC1J1G: Technical Specifications

-

Model Number: DS3800NSFC1J1G

-

Manufacturer: General Electric (GE Fanuc)

-

Product Type: Switch Field Control / Intelligent Field Interface Board

-

Series: DS3800, Mark IV Speedtronic

-

Form Factor: 6BA Euro-card (≈ 233 × 160 mm)

-

Back-Plane Connector: Dual 40-pin header (J1/J2)

-

Input Channels: 16 intelligent (dry contact or 24 Vdc, auto-sensing)

-

Input Impedance: Auto-ranging 10 kΩ–1 MΩ (J1G feature)

-

Isolation: 1500 Vdc channel-to-ground; group-isolated in 4-channel banks

-

Update Rate: 2 ms status; 100 ms health metrics

-

Diagnostics: Contact resistance trending, bounce pattern analysis, wiring integrity (J1G enhancements)

-

Predictive Algorithm: Machine-learning-based failure prediction (J1G feature)

-

Power Demand: +5 V @ 0.7 A, +3.3 V @ 0.4 A, +24 V @ 0.3 A from rack 2PL bus

-

Operating Temperature: 0 – 60 °C

-

Weight: ≈ 0.25 kg

-

Construction: Epoxy-sealed copper traces—non-repairable

DS3800NSFC1J1G

Core Features & Customer Value

Predictive Failure Detection: The J1G revision analyzes contact resistance trends and bounce patterns to predict switch failure 50–200 hours before functional loss. For maintenance planners, this transforms emergency repairs into scheduled outages, reducing unplanned downtime by 60–80% in critical switch applications.

Auto-Sensing Input Configuration: The card automatically detects dry contact vs. 24 Vdc inputs and adjusts impedance accordingly. For commissioning engineers, this eliminates jumper configuration errors and allows mixed input types without manual setup—reducing startup time and configuration mistakes.

Intelligent Debounce Adaptation: The machine-learning algorithm adapts debounce timing based on historical bounce patterns for each switch. For protection engineers, this provides faster response on well-maintained switches while preventing false trips on aging contacts—optimizing both speed and security.

Epoxy-Sealed Construction: All internal copper is encapsulated in high-temperature epoxy. In coastal or industrial environments with conductive dust and high humidity, this prevents trace-to-trace shorting that would compromise diagnostic integrity after ten-plus years. The trade-off is non-repairability—internal faults require whole-card exchange—but this is offset by reduced troubleshooting time and single-spare stocking rather than maintaining a repair bench.

Typical Applications

In combined-cycle power plants, this board installs in the Mark IV turbine control core where it monitors the complete set of turbine protective switches with predictive intelligence. The health trending identifies which vibration switch or pressure transmitter is developing contact problems, allowing replacement during the next scheduled outage rather than after a spurious trip.

On utility-scale EX2000 static exciters, the same card tracks diode-fail contacts and cooling system switches with wiring integrity monitoring. The predictive algorithm detects increasing contact resistance from corrosion before it causes false “open” indications, preventing unnecessary exciter trips.

Mechanical-drive gas compressors in remote pipeline stations frequently use this part number for critical shutdown switches where maintenance access is limited. The 200-hour failure prediction window allows coordination with scheduled pipeline maintenance windows, avoiding separate compressor trips.