Description

DS3800NRFA1F1E Product Overview

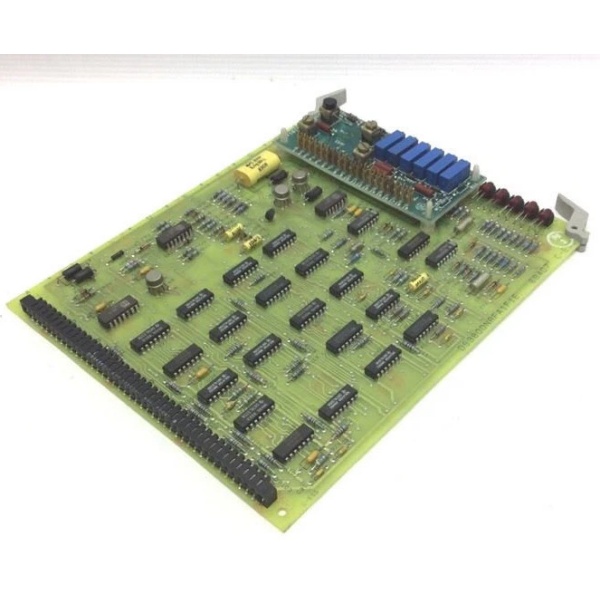

The DS3800NRFA1F1E is a ramp-and-follower auxiliary board used inside GE Mark IV turbine and exciter control racks. It sits between the main CPU (typically the NDIA data bus) and the high-voltage bridge cards, providing two critical services:

The DS3800NRFA1F1E is a ramp-and-follower auxiliary board used inside GE Mark IV turbine and exciter control racks. It sits between the main CPU (typically the NDIA data bus) and the high-voltage bridge cards, providing two critical services:

-

Ramp Generation – It produces smooth, time-based acceleration and deceleration reference curves for the turbine fuel valve or exciter field supply. These ramps prevent thermal shock to the rotor and mechanical drive-train during start-up, load changes, or emergency stops.

-

Signal Buffering – It scales and isolates feedback signals (bridge volts, armature current, LVDT position) so the 5 V CPU A/D converters are protected from the 600 V class power electronics.

Because the board is epoxy-sealed and non-repairable, it is treated as a line-replaceable module; a lightning hit or over-voltage event that damages any trace means the whole card is swapped, not reworked. The 6BA07 Euro-card form-factor plugs straight into the Mark IV VME-style rack and is fully hot-swappable when the rack is powered down.

DS3800NRFA1F1E Technical Specifications

-

Model Number: DS3800NRFA1F1E

-

Manufacturer: General Electric

-

Product Type: Ramp & Follower / Auxiliary I/O Interface Board

-

Series: DS3800, Mark IV Speedtronic

-

Form Factor: 6BA07 Euro-card (≈ 233 × 160 mm)

-

Back-Plane Connector: 40-pin dual-row header (J1/J2)

-

Field I/O Interface: High-density pin headers for analog & digital feedback

-

Isolation: 1500 Vdc channel-to-ground (group isolated)

-

Operating Temperature: 0 – 60 °C

-

Construction: Epoxy-sealed copper traces—non-repairable

-

Power Demand: +5 V @ 0.9 A, ±15 V @ 0.2 A from rack 2PL bus

-

Ramp Time Range: 0.1 – 999 s (jumper-selectable time constants)

-

Follower Accuracy: ±0.1 % of full-scale set-point

-

Weight: ≈ 0.35 kg

Core Features & Customer Value

Precision Ramp Control: The on-board R-C timing network generates linear acceleration and deceleration curves that are repeatable to ±0.1 %. For the operator this means the turbine reaches synchronous speed without overshoot, reducing thermal stress on the rotor and extending major-inspection intervals.

Epoxy-Sealed Construction: All copper layers are encapsulated in a high-temperature epoxy. In environments with high humidity, dust, or conductive contamination the seal prevents trace-to-trace shorting, a common failure mode in open-frame boards after ten-plus years of service.

Hot-Swap Euro-Card Footprint: The 6BA07 form-factor slides straight into the existing Mark IV card file—no mounting brackets or wiring changes required. For maintenance crews this translates to a five-minute replacement instead of a half-shift re-cabling job.

Non-Repairable Design Philosophy: Because the board is treated as a consumable spare, plants stock one instead of maintaining a repair bench. When a surge event damages any internal layer, technicians simply exchange the card and return the failed unit for factory scrap—no troubleshooting time lost.

DS3800NRFA1F1E

Typical Applications

In combined-cycle power plants the board is installed in the Mark IV turbine control core where it generates the fuel-valve ramp during automatic start-up. It also buffers the exhaust-temperature thermocouple string so the CPU receives a noise-free signal while the bridge cards sit at 480 VAC.

In utility-scale EX2000 static exciters it provides the field-current ramp reference, ensuring the generator voltage builds smoothly to grid-match levels without overshoot that would trip the synchronization relay. The follower circuit tracks the manual raise/lower commands from the operator so the exciter responds predictably during VAR loading.

Frequently the same card is used on mechanical-drive gas compressors to ramp inlet guide-vanes, preventing surge during rapid acceleration. Its ability to scale both voltage and current feedback makes it a universal “analog front-end” for any Mark IV loop that needs smooth, time-based control.