Description

DS3800NPSE1C1B: Product Overview

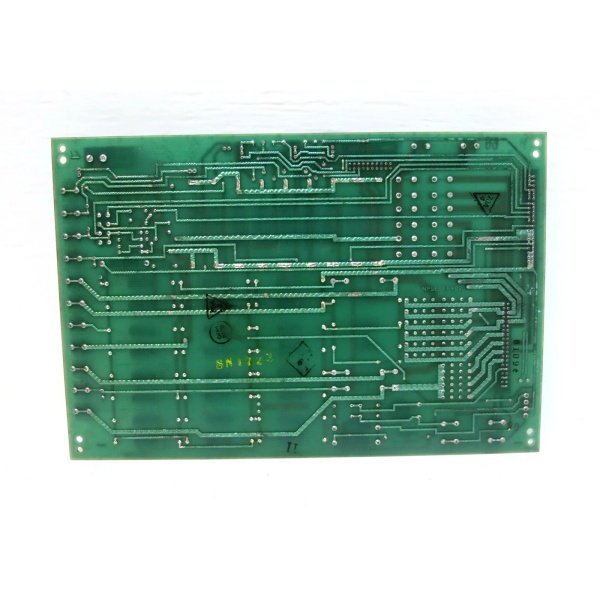

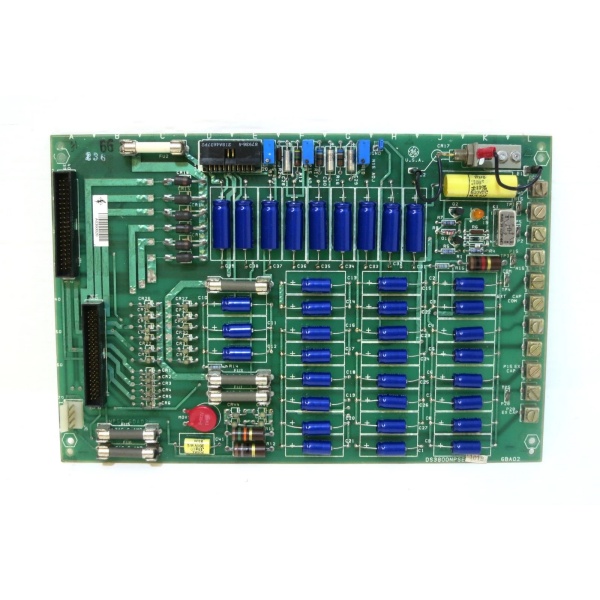

The DS3800NPSE1C1B serves as the primary power conversion and distribution module within GE’s Speedtronic Mark IV turbine control architecture. Positioned in the power supply section of the control cabinet, this board converts facility AC or DC input power into the stable, regulated DC voltages required by the Mark IV’s sensitive electronic components. The “NPSE” designation identifies this as part of the Network Power Supply family, specifically designed for the demanding requirements of continuous-duty turbine control applications.

The board incorporates switching power conversion technology to generate multiple regulated DC outputs including +5V for digital logic circuits and ±15V for analog signal conditioning and operational amplifier circuits. These power rails must maintain tight voltage regulation and low ripple characteristics to ensure the precision required for turbine control algorithms, speed measurement circuits, and analog signal processing. The power supply design includes overcurrent protection, thermal shutdown, and input surge suppression to protect downstream components from electrical disturbances common in industrial environments.

As a member of the DS3800 series, the NPSE1C1B adheres to the standardized form factor and mounting scheme established for the Mark IV platform. This standardization enables rapid field replacement and reduces spare parts inventory requirements for facilities maintaining legacy turbine control systems. The board’s design reflects GE’s field-proven approach to industrial power supplies: conservative component derating, extensive filtering, and thermal management features that ensure continuous operation in the elevated temperatures and vibration environments typical of power generation facilities.

DS3800NPSE1C1B

DS3800NDAC1D1E: Technical Specifications

-

Model Number: DS3800NPSE1C1B

-

Manufacturer: General Electric

-

Product Type: Power Supply Board

-

System Compatibility: Speedtronic Mark IV Turbine Control

-

Output Voltages: +5V DC regulated, ±15V DC regulated

-

Input Voltage Range: Compatible with Mark IV system DC input (typically 24VDC or 125VDC system bus)

-

Operating Temperature: -20°C to +70°C

-

Storage Temperature: -40°C to +85°C

-

Mounting: Standard Mark IV card rack/cage mounting

-

Power Conversion: Switching power supply architecture

-

Protection Features: Overcurrent protection, thermal shutdown, input surge suppression

-

Regulation: Tight voltage regulation and low ripple characteristics

-

Cooling: Natural convection cooling with forced air assistance from system fans

-

Weight: Approximately 0.5 lbs (0.23 kg)

Core Features & Customer Value

Multi-Rail Power Supply for Complete System Support: The board generates the three primary voltage rails required by Mark IV electronics: +5V for digital processors and logic circuits, +15V for analog signal conditioning, and -15V for operational amplifier negative supply rails. This integrated approach eliminates the need for multiple separate power supplies, reducing wiring complexity and potential failure points. For plant operators, this consolidation translates to higher system reliability and simplified maintenance procedures.

Wide Operating Temperature Range for Harsh Environments: The -20°C to +70°C operating range accommodates the temperature extremes found in turbine control rooms, from cold winter startups to hot summer operation with reduced HVAC capacity. The board’s thermal design includes temperature-compensated voltage references and derated components that maintain regulation accuracy across this range. This environmental tolerance ensures continuous operation even when cooling systems are compromised during facility upsets.

Industrial-Grade Protection and Filtering: The integrated protection features safeguard the entire control system from electrical disturbances common in power plants. Input surge suppression protects against voltage transients from motor starting, switchgear operation, and lightning-induced events. Overcurrent protection prevents damage from short circuits in field wiring, while thermal shutdown protects the power supply itself from overtemperature conditions. For maintenance teams, these protective features reduce the frequency of cascade failures that can occur when power supply faults propagate to downstream boards.

Hot-Swappable Design for Maximum Availability: While power supplies require careful handling during replacement, the standardized DS3800 form factor enables rapid board exchange when proper procedures are followed. The card-edge connector design and positive retention hardware ensure reliable electrical connection even under vibration. For baseload power plants where availability premiums are high, this maintainability is critical for minimizing forced outage duration during power supply failures.

DS3800NPSE1C1B

Typical Applications

The DS3800NPSE1C1B is deployed in gas turbine control systems to power the microprocessor boards, analog input/output modules, and communication interfaces that govern fuel flow, inlet guide vane positioning, and auxiliary system control. In a typical Frame 7 or Frame 9 heavy-duty gas turbine, multiple NPSE boards may distribute power across different sections of the control cabinet to minimize single-point failures and reduce voltage drop issues in large installations.

In steam turbine generator control applications, this board provides clean power for speed control circuits, governor valve actuators, and generator protective relays. The ±15V rails are particularly critical for precision speed measurement circuits that must resolve turbine speed to within thousandths of a percent for grid frequency control. The low-noise characteristics of the power supply ensure that analog signals from proximity probes and pressure transmitters maintain the accuracy required for turbine protection systems.

The module also serves in combined-cycle power plant integrated control systems, where it powers the distributed control interfaces that coordinate gas turbine, steam turbine, and heat recovery steam generator (HRSG) operation. The stable voltage regulation ensures that control algorithms execute consistently across varying ambient conditions and load levels, maintaining optimal efficiency during complex load-following operations.