Description

DS3800NPIA1B1C: Product Overview

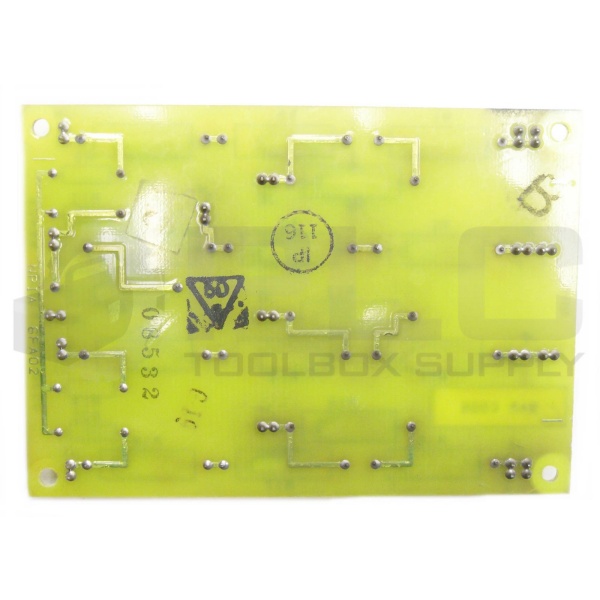

The board serves as a field input interface and personality adaptation module within the Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this unit functions as the primary gateway through which field sensor data and discrete status inputs enter the control system. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring that critical field data is accurately captured and transmitted to the central processors with appropriate scaling and conditioning.

As a node personality input adapter, the unit manages the electrical interface between diverse field devices and the standardized Mark IV backplane. It receives analog signals from transmitters, thermocouples, and RTDs, as well as discrete inputs from switches, relays, and limit devices, conditioning these signals to logic levels compatible with the microprocessor-based control algorithms. The board’s personality architecture—implemented through socketed EPROM modules—allows the same hardware to adapt to different input ranges, sensor types, and scaling factors without physical modifications, supporting the varied instrumentation requirements across different turbine models and applications.

The board features robust signal conditioning circuitry that filters electrical noise, provides surge protection, and converts field signals to standardized internal levels. High-density modular backplane connectors ensure reliable data transfer to the central processors while maintaining the isolation necessary to protect sensitive electronics from field-side transients. The 6BA03 form factor indicates standard Mark IV dimensions with appropriate mounting hardware for secure installation in vibration-prone turbine environments.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture allows input conditioning to execute autonomously at the I/O level while maintaining deterministic synchronization with the control processors, ensuring that field data is sampled and processed within the timeframes required for turbine protection and control.

GE DS3800NPIA1B1C

DS3800NPIA1B1C: Technical Specifications

-

Model Number: DS3800NPIA1B1C

-

Manufacturer: General Electric

-

Product Type: Node Personality Input Adapter Board

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Input Types: Analog (4-20mA, thermocouple, RTD) and discrete (24VDC, 125VDC) field inputs

-

Personality Configuration: EPROM-based scaling and range selection

-

Channels: Multiple input channels (typically 8-16 depending on configuration)

-

Signal Conditioning: Filtering, surge protection, and level translation

-

Backplane Interface: High-density modular connector (AMD 218A4553-1 compatible)

-

Form Factor: 6BA03 standard Mark IV board format

-

Isolation: Galvanic isolation between field inputs and control logic

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Mounting: Standard Mark IV rack slot with retention hardware

Part 4: Core Features & Customer Value

Personality-Based Input Adaptation:

The board utilizes socketed EPROM modules to store personality data that defines input scaling, range selection, and sensor type configuration. This architecture enables the same physical board to support different field instruments—whether thermocouples on exhaust gas systems, 4-20mA pressure transmitters on lube oil systems, or discrete limit switches on valve positions—merely by changing the personality firmware. For facilities with mixed turbine fleets operating different sensor types, this standardization reduces spare parts inventory; instead of stocking model-specific input boards, maintenance teams can maintain generic hardware and configure it via EPROM exchange.

The board utilizes socketed EPROM modules to store personality data that defines input scaling, range selection, and sensor type configuration. This architecture enables the same physical board to support different field instruments—whether thermocouples on exhaust gas systems, 4-20mA pressure transmitters on lube oil systems, or discrete limit switches on valve positions—merely by changing the personality firmware. For facilities with mixed turbine fleets operating different sensor types, this standardization reduces spare parts inventory; instead of stocking model-specific input boards, maintenance teams can maintain generic hardware and configure it via EPROM exchange.

Comprehensive Signal Conditioning:

Integrated filtering and surge suppression circuitry protects the sensitive Mark IV processors from electrical transients and noise that commonly appear on field wiring. The board provides galvanic isolation between field circuits and control logic, preventing ground loop currents from corrupting measurements or damaging electronics. This isolation is particularly critical in gas turbine applications where high-voltage ignition systems and variable frequency drives generate substantial electrical noise that could otherwise propagate into low-level analog measurements.

Integrated filtering and surge suppression circuitry protects the sensitive Mark IV processors from electrical transients and noise that commonly appear on field wiring. The board provides galvanic isolation between field circuits and control logic, preventing ground loop currents from corrupting measurements or damaging electronics. This isolation is particularly critical in gas turbine applications where high-voltage ignition systems and variable frequency drives generate substantial electrical noise that could otherwise propagate into low-level analog measurements.

Hot-Swappable Design with Secure Retention:

The board supports replacement within the Mark IV TMR architecture, allowing technicians to service input circuits without turbine shutdown. Standardized retention hardware ensures positive mechanical engagement despite the vibration environment typical of turbine enclosures. This maintainability ensures that instrument failures—such as burned-out input channels or calibration drift—can be addressed during scheduled maintenance windows or emergency repairs without forcing extended outages.

The board supports replacement within the Mark IV TMR architecture, allowing technicians to service input circuits without turbine shutdown. Standardized retention hardware ensures positive mechanical engagement despite the vibration environment typical of turbine enclosures. This maintainability ensures that instrument failures—such as burned-out input channels or calibration drift—can be addressed during scheduled maintenance windows or emergency repairs without forcing extended outages.

Deterministic Data Acquisition:

Designed for real-time control applications, the board samples and conditions field inputs with deterministic timing that supports the Mark IV’s protective algorithms. Whether monitoring exhaust gas temperatures for combustion control or bearing vibration for machinery protection, the input adapter ensures that data reaches the central processors within the microseconds required for safety-critical decisions. This predictable performance supports Safety Integrity Level (SIL) requirements for turbine protection systems.

Designed for real-time control applications, the board samples and conditions field inputs with deterministic timing that supports the Mark IV’s protective algorithms. Whether monitoring exhaust gas temperatures for combustion control or bearing vibration for machinery protection, the input adapter ensures that data reaches the central processors within the microseconds required for safety-critical decisions. This predictable performance supports Safety Integrity Level (SIL) requirements for turbine protection systems.

Flexible Configuration for Retrofit Applications:

The personality architecture accommodates legacy field instrumentation during turbine control upgrades. When replacing older turbine controls with Mark IV systems, this board can be configured to match existing sensor ranges and signal types, eliminating the need to replace field transmitters or rewire junction boxes. This compatibility reduces capital costs and commissioning time during modernization projects while preserving proven field instrumentation investments.

The personality architecture accommodates legacy field instrumentation during turbine control upgrades. When replacing older turbine controls with Mark IV systems, this board can be configured to match existing sensor ranges and signal types, eliminating the need to replace field transmitters or rewire junction boxes. This compatibility reduces capital costs and commissioning time during modernization projects while preserving proven field instrumentation investments.

GE DS3800NPIA1B1C

Part 5: Typical Applications

Gas Turbine Exhaust Temperature Monitoring:

The board is deployed in GE Frame 5, 6, and 7 gas turbines to condition thermocouple signals from the exhaust gas temperature monitoring system. In these applications, the personality EPROM configures the board for Type K thermocouple inputs with cold junction compensation, allowing precise measurement of combustion gas temperatures exceeding 1,000°F. The board’s filtering circuitry attenuates noise from the high-voltage ignition exciters that share the turbine compartment, ensuring that temperature data used for combustion control and overtemperature protection remains accurate despite the electrically hostile environment.

The board is deployed in GE Frame 5, 6, and 7 gas turbines to condition thermocouple signals from the exhaust gas temperature monitoring system. In these applications, the personality EPROM configures the board for Type K thermocouple inputs with cold junction compensation, allowing precise measurement of combustion gas temperatures exceeding 1,000°F. The board’s filtering circuitry attenuates noise from the high-voltage ignition exciters that share the turbine compartment, ensuring that temperature data used for combustion control and overtemperature protection remains accurate despite the electrically hostile environment.

Steam Turbine Lube Oil and Hydraulic Systems:

In steam turbine applications within paper mills and petrochemical facilities, this board interfaces with pressure transmitters and temperature sensors on bearing lubrication systems and electro-hydraulic control (EHC) units. The personality configuration adapts the inputs for 4-20mA loop-powered transmitters monitoring bearing oil pressure and RTDs measuring oil temperature. The board’s isolation prevents ground loops that could otherwise occur when sensors are mounted on grounded turbine casings while the control electronics reference a different ground potential.

In steam turbine applications within paper mills and petrochemical facilities, this board interfaces with pressure transmitters and temperature sensors on bearing lubrication systems and electro-hydraulic control (EHC) units. The personality configuration adapts the inputs for 4-20mA loop-powered transmitters monitoring bearing oil pressure and RTDs measuring oil temperature. The board’s isolation prevents ground loops that could otherwise occur when sensors are mounted on grounded turbine casings while the control electronics reference a different ground potential.

Aeroderivative Package Instrumentation:

For LM6000 and LM2500 units, the board manages the diverse instrumentation typical of aeroderivative packages, including inlet air temperature sensors, fuel system pressure switches, and compartment ventilation status inputs. The compact 6BA03 form factor fits within the limited control enclosure space of these units while providing the input density required for package monitoring. Personality configurations accommodate the different sensor types and scaling factors common to aeroderivative installations, which often differ from heavy-duty frame turbine standards.

For LM6000 and LM2500 units, the board manages the diverse instrumentation typical of aeroderivative packages, including inlet air temperature sensors, fuel system pressure switches, and compartment ventilation status inputs. The compact 6BA03 form factor fits within the limited control enclosure space of these units while providing the input density required for package monitoring. Personality configurations accommodate the different sensor types and scaling factors common to aeroderivative installations, which often differ from heavy-duty frame turbine standards.

Safety Instrumented System Inputs:

Within the Mark IV’s integrated protection architecture, this board provides the input channels for safety-critical measurements such as manual emergency stop buttons, overspeed detector inputs, and bearing vibration switches. The deterministic response and isolation features ensure that these protective inputs are reliably detected and transmitted to the voting logic within the timeframes required for SIL-rated safety functions. The personality firmware configures these channels with appropriate debouncing and filtering to prevent nuisance trips from contact bounce or electrical noise while maintaining sensitivity to genuine safety events.

Within the Mark IV’s integrated protection architecture, this board provides the input channels for safety-critical measurements such as manual emergency stop buttons, overspeed detector inputs, and bearing vibration switches. The deterministic response and isolation features ensure that these protective inputs are reliably detected and transmitted to the voting logic within the timeframes required for SIL-rated safety functions. The personality firmware configures these channels with appropriate debouncing and filtering to prevent nuisance trips from contact bounce or electrical noise while maintaining sensitivity to genuine safety events.

Auxiliary System Status Monitoring:

The board monitors discrete status inputs from auxiliary equipment such as lube oil pump running status, cooling fan proof-of-flow switches, and hydraulic power unit pressure switches. These inputs support the sequential control logic that ensures auxiliaries are properly operating before the turbine is started or loaded. The board’s ability to handle both AC and DC discrete inputs (depending on personality configuration) accommodates the mixed voltage levels often found in plant auxiliary systems, particularly in older installations with legacy 125VDC control circuits.

The board monitors discrete status inputs from auxiliary equipment such as lube oil pump running status, cooling fan proof-of-flow switches, and hydraulic power unit pressure switches. These inputs support the sequential control logic that ensures auxiliaries are properly operating before the turbine is started or loaded. The board’s ability to handle both AC and DC discrete inputs (depending on personality configuration) accommodates the mixed voltage levels often found in plant auxiliary systems, particularly in older installations with legacy 125VDC control circuits.