Description

DS3800NMEC1C1B: Product Overview

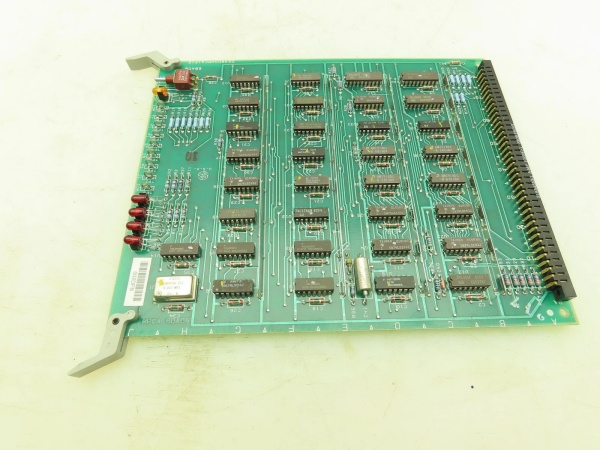

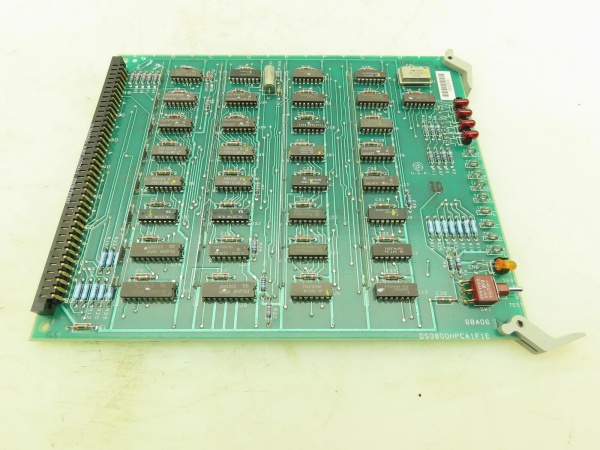

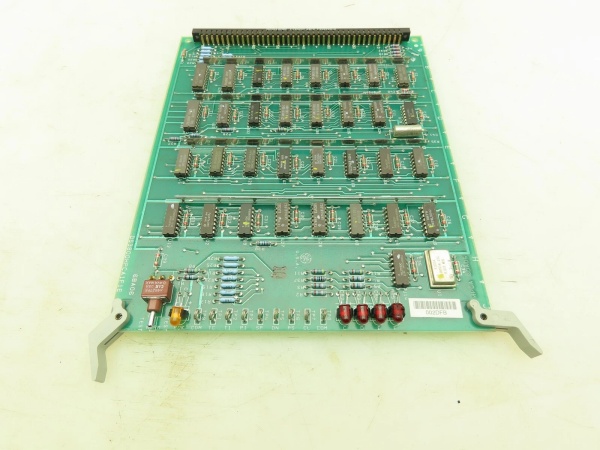

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as a high-speed pulse accumulator for event monitoring applications. It captures incoming pulses from shaft encoders, proximity probes, or digital fault contacts, time-stamps each occurrence with 1 ms resolution in local SRAM, and presents accumulated counts to the main CPU over the NDIA parallel bus. The C1B revision indicates standard commercial qualification suitable for non-safety-critical applications where C-ESS essential-service rating is not required.

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as a high-speed pulse accumulator for event monitoring applications. It captures incoming pulses from shaft encoders, proximity probes, or digital fault contacts, time-stamps each occurrence with 1 ms resolution in local SRAM, and presents accumulated counts to the main CPU over the NDIA parallel bus. The C1B revision indicates standard commercial qualification suitable for non-safety-critical applications where C-ESS essential-service rating is not required.

The epoxy-sealed construction makes this a line-replaceable module—internal faults require complete card swap rather than field repair. The module hot-swaps when the rack is powered down, and its low profile allows adjacent-slot population without additional cooling. As part of the DS3800 family, it benefits from the Mark IV platform’s deterministic 2 ms control interval and extensive installed base in power generation applications.

GE DS3800HPCA1F1E

DS3800NMEC1C1B: Technical Specifications

-

Model Number: DS3800NMEC1C1B

-

Manufacturer: General Electric (GE Fanuc)

-

Product Type: Micro-Event Counter / High-Speed Pulse Counting Board

-

Series: DS3800, Mark IV Speedtronic

-

Form Factor: 6BA Euro-card (≈ 233 × 160 mm)

-

Qualification: Standard commercial (non-C-ESS)

-

Back-Plane Connector: Dual 40-pin header (J1/J2)

-

Input Type: Differential TTL / 24 Vdc pulse (jumper-selectable)

-

Count Rate: ≤ 2 MHz (typical Mark IV bus limit)

-

Time-Stamp Resolution: 1 ms (synchronized to CPU real-time clock)

-

Isolation: 1500 Vdc field-to-logic; opto-coupled inputs

-

Power Demand: +5 V @ 0.6 A, +15 V @ 0.2 A from rack 2PL bus

-

Operating Temperature: 0 – 60 °C

-

Weight: ≈ 0.22 kg

-

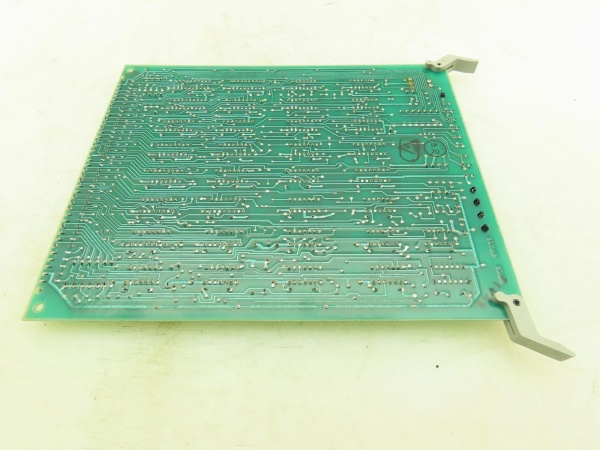

Construction: Epoxy-sealed copper traces—non-repairable

Core Features & Customer Value

Cost-Optimized Commercial Grade: The C1B revision provides identical electrical performance to C-ESS versions at reduced cost for applications where extended qualification testing is not mandated. For plant owners with budget constraints, this enables reliable event monitoring in auxiliary systems without premium pricing for safety-critical ratings.

High-Speed Event Counting with Time-Stamping: The on-board counter latches each pulse with 1 ms resolution, enabling precise correlation of events with turbine operating states. For reliability engineers, this provides accurate root-cause analysis when blade-pass frequency anomalies or equipment fault events occur, supporting predictive maintenance programs.

Epoxy-Sealed Construction: All internal copper is encapsulated in high-temperature epoxy. In coastal or industrial environments with conductive dust and high humidity, this prevents trace-to-trace shorting that would cause random “EVENT COUNTER FAIL” alarms after ten-plus years. The trade-off is non-repairability—internal faults require whole-card exchange—but this is offset by reduced troubleshooting time and single-spare stocking rather than maintaining a repair bench.

GE DS3800HPCA1F1E

Typical Applications

In industrial cogeneration plants with smaller gas turbines, this board installs in the Mark IV control core to count blade-pass events from the main shaft encoder. During start-up, the CPU uses time-stamped counts to compute instantaneous speed and acceleration rate; during normal operation, the data supports vibration analysis and bearing condition monitoring.

On mechanical-drive gas compressors in pipeline booster stations, the same card accumulates flow-meter pulses and engine cycle counts. The commercial-grade qualification is adequate for these non-safety-critical applications where redundant protection systems are not required.

Auxiliary equipment in combined-cycle plants—such as cooling tower fans and fuel gas compressors—frequently use this part number for run-time metering and maintenance scheduling. The 1 ms time-stamping provides sufficient resolution for equipment utilization tracking without the cost premium of C-ESS qualification.