Description

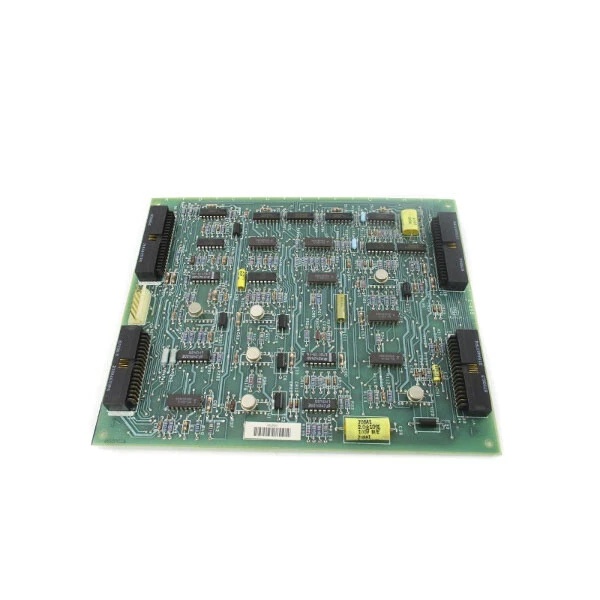

DS3800NLCA1D1C: Product Overview

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as a digital logic interface between the low-voltage processor and field-level devices. It buffers 5 V CMOS signals from the CPU, converts them to 24 Vdc field levels for solenoids and contactors, executes fast auxiliary control sequences (pump alternation, fan staging, valve interlocks), and provides 1500 Vdc isolation to protect the processor from ground loops and switching transients. The D1C revision includes enhanced noise immunity circuitry for operation in electrically harsh environments near variable-frequency drives and high-power SCR bridges.

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as a digital logic interface between the low-voltage processor and field-level devices. It buffers 5 V CMOS signals from the CPU, converts them to 24 Vdc field levels for solenoids and contactors, executes fast auxiliary control sequences (pump alternation, fan staging, valve interlocks), and provides 1500 Vdc isolation to protect the processor from ground loops and switching transients. The D1C revision includes enhanced noise immunity circuitry for operation in electrically harsh environments near variable-frequency drives and high-power SCR bridges.

The epoxy-sealed construction makes this a line-replaceable module—internal faults require complete card swap rather than field repair. The module hot-swaps when the rack is powered down, and its low profile allows adjacent-slot population without additional cooling. As part of the DS3800 family, it benefits from the Mark IV platform’s deterministic 2 ms control interval and extensive installed base in power generation applications.

GE DS3800NGRC1F1F

DS3800NLCA1D1C: Technical Specifications

-

Model Number: DS3800NLCA1D1C

-

Manufacturer: General Electric (GE Fanuc)

-

Product Type: Logic Control Auxiliary / Digital Buffer Board

-

Series: DS3800, Mark IV Speedtronic

-

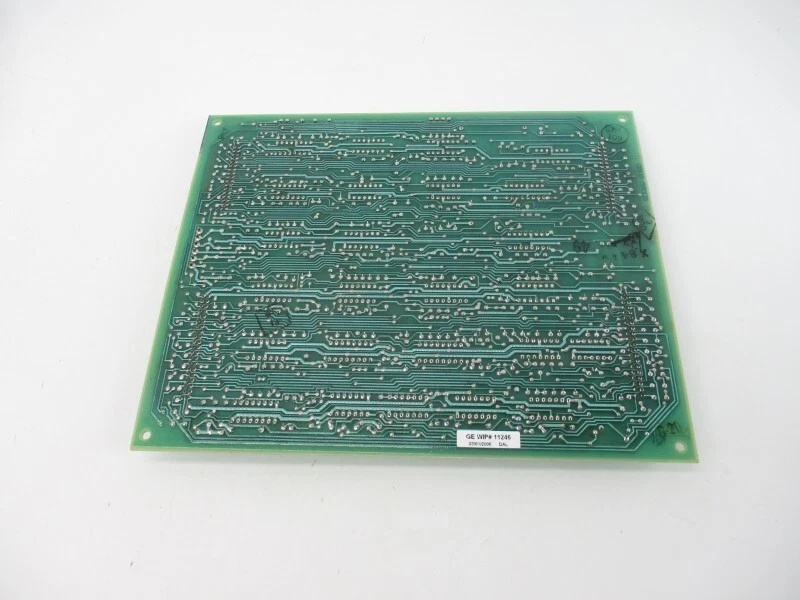

Form Factor: 6BA Euro-card (≈ 233 × 160 mm)

-

Back-Plane Connector: Dual 40-pin header (J1/J2)

-

Logic Levels: 5 V CMOS/TTL (CPU side); 24 Vdc (field side)

-

Isolation: 1500 Vdc field-to-logic; opto-coupled I/O lines

-

Update Rate: 2 ms (synchronized to CPU scan)

-

Noise Immunity: Enhanced common-mode rejection (D1C improvement)

-

Power Demand: +5 V @ 0.8 A, +24 V @ 0.5 A from rack 2PL bus

-

Operating Temperature: 0 – 60 °C

-

Weight: ≈ 0.22 kg

-

Construction: Epoxy-sealed copper traces—non-repairable

Core Features & Customer Value

Enhanced Noise Immunity: The D1C revision includes improved common-mode chokes and filtered power entry that reduce susceptibility to conducted EMI from adjacent VFDs and exciter bridges. For installations in crowded electrical compartments, this eliminates spurious input transitions that cause nuisance trips and equipment cycling.

Fast Auxiliary Sequence Execution: The local logic array executes pump alternation, fan staging, and valve interlock subroutines without burdening the main CPU. This guarantees deterministic response even when the central processor is busy with turbine sequencing or communications, preventing auxiliary-trip delays during critical start-up phases.

Epoxy-Sealed Construction: All internal copper is encapsulated in high-temperature epoxy. In coastal or industrial environments with conductive dust and high humidity, this prevents trace-to-trace shorting that would cause random “LOGIC FAIL” alarms after ten-plus years. The trade-off is non-repairability—internal faults require whole-card exchange—but this is offset by reduced troubleshooting time and single-spare stocking rather than maintaining a repair bench.

GE DS3800NGRC1F1F

Typical Applications

In combined-cycle power plants, this board installs in the Mark IV turbine control core where it executes the lube-oil pump alternation logic, cooling-fan staging sequence, and hydraulic trip solenoid control. The enhanced noise immunity is critical in modern installations where VFD-driven auxiliaries generate significant electrical interference.

On utility-scale EX2000 static exciters, the same card manages the brushless-exciter cooling-fan starter logic and the field-discharge contactor interlock. The 1500 V isolation prevents SCR switching transients from corrupting CPU data during load rejection events.

Mechanical-drive gas compressors frequently use this part number to sequence the inlet-guide-vane hydraulic pump and the anti-surge valve solenoids. The fast 2 ms update ensures rapid valve response during surge events, protecting the compressor from mechanical damage.