Description

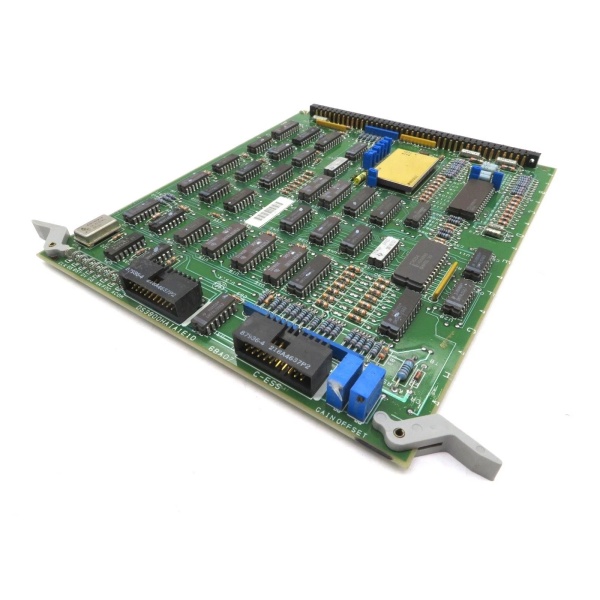

DS3800NHVM1E1D: Product Overview

The DS3800NHVM1E1D serves as a high voltage control and power switching module within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this board manages high voltage power circuits for low horsepower auxiliary equipment while providing galvanic isolation and transient protection for sensitive microprocessor-based control logic. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring that high voltage switching functions remain synchronized and fault-tolerant.

As a high voltage low horsepower (LO HP) control board, the unit integrates silicon-controlled rectifier (SCR) and high-power diode technology to switch and condition electrical power for auxiliary systems such as cooling fans, lube oil pumps, and hydraulic power units. The board’s relay-based logic provides robust electromechanical isolation between the Mark IV’s low-voltage logic circuits (5V/15V TTL) and high voltage auxiliary drive systems (120-480VAC or high voltage DC). This isolation prevents electrical transients from propagating into control logic while enabling the Mark IV to safely energize and de-energize high power auxiliary equipment.

The board belongs to the DS3800 series of the Mark IV platform, designed for heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture requires that high voltage switching components maintain deterministic response times and fail-safe operation characteristics. The board’s design supports the Mark IV’s hot-swappable maintenance philosophy when properly sequenced with redundant channels, allowing replacement without turbine shutdown despite handling high voltage power circuits.

DS3800HAIA1E1D

DS3800NHVM1E1D: Technical Specifications

-

Model Number: DS3800NHVM1E1D

-

Manufacturer: General Electric

-

Product Type: High Voltage Low Horsepower Control Board

-

Series: GE Speedtronic Mark IV

-

High Voltage Components: 59 discrete diodes (17 standard red diodes, 26 black/silver diodes, 10 black diodes, 6 clear/filmy diodes)

-

Relay Logic: 13 electromechanical relays (high-current black housing) for power switching and isolation

-

Passive Components: 76 resistors (48 large grey/brown/black base, 17 average light blue, 11 small light blue with color-coded stripes); 30 capacitors (6 large metal can electrolytic, 12 large black electrolytic, 12 average white ceramic)

-

Status Indication: 12 raised red LEDs for power and switching status visibility

-

Electrical Connections: 8 high-current male pin connectors for high voltage cable interfacing

-

Circuit Protection: Metal oxide varistors (MOVs) and surge suppression diodes for transient protection

-

Operating Voltage: High voltage auxiliary circuits (120-480VAC or HV DC, site-specific)

-

Backplane Interface: Standard Mark IV high-density modular connector with retention levers

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Humidity: 5% to 95% non-condensing

-

Enclosure: Designed for NEMA 1/12 control cabinet installation with appropriate arc flash protection

Part 4: Core Features & Customer Value

High Voltage Isolation and Safety: The primary function of this board is to provide robust electrical isolation between the Mark IV’s delicate microprocessor circuits and high voltage auxiliary power systems. The thirteen electromechanical relays offer physically separated contacts rated for high voltage switching, ensuring that faults in auxiliary equipment cannot propagate into control logic. For plant safety engineers, this isolation architecture prevents cascade failures where a shorted motor or cable fault could damage expensive processor boards or create personnel safety hazards within the control cabinet.

Comprehensive Component Protection: The board integrates fifty-nine discrete diodes arranged in rectifier configurations and反向偏置 protection networks to manage high voltage transients and inductive kickback from relay coils and motor loads. The diverse capacitor bank (thirty capacitors total) filters switching noise and provides localized energy storage for relay operation. For maintenance technicians, this extensive protection circuitry reduces catastrophic failure modes—when high voltage events occur, the board’s protection components typically sacrifice themselves to protect downstream logic, allowing simple diode or capacitor replacement rather than complete board failure.

Visual Diagnostics for Troubleshooting: The twelve raised red LEDs provide immediate visual confirmation of relay states, power availability, and protection circuit status without requiring multimeter testing or diagnostic software connections. During commissioning or troubleshooting, technicians can verify that high voltage circuits are properly energized, that relays are picking up as commanded by the control logic, and that protection circuits are active. This visibility reduces mean time to repair (MTTR) by allowing rapid identification of whether a fault lies in the control command, the interface board, or the field wiring and auxiliary equipment.

Heavy-Duty Construction for Industrial Longevity: The board utilizes large metal can electrolytic capacitors and high-wattage resistors with precise color-coded tolerance bands to maintain calibration over thermal cycling. The eight high-current male connectors ensure reliable high voltage connections that resist vibration-induced loosening in turbine environments subject to mechanical harmonics. For facility managers operating in continuous-process industries, this industrial-grade construction ensures years of reliable operation despite the thermal and vibrational stresses inherent in power generation environments, reducing the frequency of costly replacements for obsolete Mark IV components.

Part 5: Typical Applications

Gas Turbine Auxiliary System Power Control:

The DS3800NHVM1E1D is deployed in GE Frame 5, 6, and 7 gas turbines to control high voltage auxiliary equipment such as cooling fans, space heaters, and hydraulic power units. In these applications, the board receives low-voltage command signals from the Mark IV microprocessor and uses its relay logic to switch 120-480VAC power to these auxiliaries. The high voltage diode arrays provide half-wave or full-wave rectification for DC auxiliary drives, while the isolation relays ensure that ground faults in fan motors or pump windings cannot disrupt the critical control electronics. The board’s LED indicators allow maintenance personnel to verify during inspections that cooling systems are energized and operational, preventing turbine trips due to overtemperature conditions.

The DS3800NHVM1E1D is deployed in GE Frame 5, 6, and 7 gas turbines to control high voltage auxiliary equipment such as cooling fans, space heaters, and hydraulic power units. In these applications, the board receives low-voltage command signals from the Mark IV microprocessor and uses its relay logic to switch 120-480VAC power to these auxiliaries. The high voltage diode arrays provide half-wave or full-wave rectification for DC auxiliary drives, while the isolation relays ensure that ground faults in fan motors or pump windings cannot disrupt the critical control electronics. The board’s LED indicators allow maintenance personnel to verify during inspections that cooling systems are energized and operational, preventing turbine trips due to overtemperature conditions.

Steam Turbine Lube Oil and Hydraulic Systems:

In steam turbine applications within paper mills, petrochemical facilities, and power plants, this board controls high voltage AC motors driving lube oil pumps and electro-hydraulic power units (EHC). The board’s relay logic provides the high current switching capacity necessary for motor starting currents, while the protection diodes suppress voltage spikes generated by contactor switching and motor inductive loads. During turbine startup sequences, the Mark IV energizes these auxiliaries through this board, ensuring that bearing lubrication and control fluid pressure are established before the turbine reaches operating speed. The board’s fail-safe characteristics ensure that loss of control power results in defined auxiliary states that protect turbine bearings.

In steam turbine applications within paper mills, petrochemical facilities, and power plants, this board controls high voltage AC motors driving lube oil pumps and electro-hydraulic power units (EHC). The board’s relay logic provides the high current switching capacity necessary for motor starting currents, while the protection diodes suppress voltage spikes generated by contactor switching and motor inductive loads. During turbine startup sequences, the Mark IV energizes these auxiliaries through this board, ensuring that bearing lubrication and control fluid pressure are established before the turbine reaches operating speed. The board’s fail-safe characteristics ensure that loss of control power results in defined auxiliary states that protect turbine bearings.

Aeroderivative Turbine Package Auxiliaries:

For LM6000 and LM2500 aeroderivative units, the board manages high voltage power to package auxiliaries including fuel forwarding pumps, compartment ventilation fans, and starter motor contactors. In these applications, the board’s compact design fits within the limited space of aeroderivative control enclosures while providing the same high voltage switching capabilities as larger frame turbine installations. The thirty capacitors on the board filter electrical noise from variable frequency drives that may be used for soft-starting large auxiliary motors, preventing harmonic distortion from affecting the Mark IV’s precision speed control circuits.

For LM6000 and LM2500 aeroderivative units, the board manages high voltage power to package auxiliaries including fuel forwarding pumps, compartment ventilation fans, and starter motor contactors. In these applications, the board’s compact design fits within the limited space of aeroderivative control enclosures while providing the same high voltage switching capabilities as larger frame turbine installations. The thirty capacitors on the board filter electrical noise from variable frequency drives that may be used for soft-starting large auxiliary motors, preventing harmonic distortion from affecting the Mark IV’s precision speed control circuits.

Excitation and Field Control Applications:

The board finds application in generator excitation systems where it controls high voltage DC field circuits or field breaker coils. The diode arrays provide rectification for field flashing circuits, while the relays manage the sequencing of field application during synchronization. The high voltage isolation ensures that field ground faults or exciter flashover events remain contained within the excitation system, protecting the main turbine control electronics. The board’s robust relay contacts handle the inductive loads associated with field breakers and discharge resistors without contact welding or excessive arcing.

The board finds application in generator excitation systems where it controls high voltage DC field circuits or field breaker coils. The diode arrays provide rectification for field flashing circuits, while the relays manage the sequencing of field application during synchronization. The high voltage isolation ensures that field ground faults or exciter flashover events remain contained within the excitation system, protecting the main turbine control electronics. The board’s robust relay contacts handle the inductive loads associated with field breakers and discharge resistors without contact welding or excessive arcing.