Description

DS3800NGTA1F1E: Product Overview

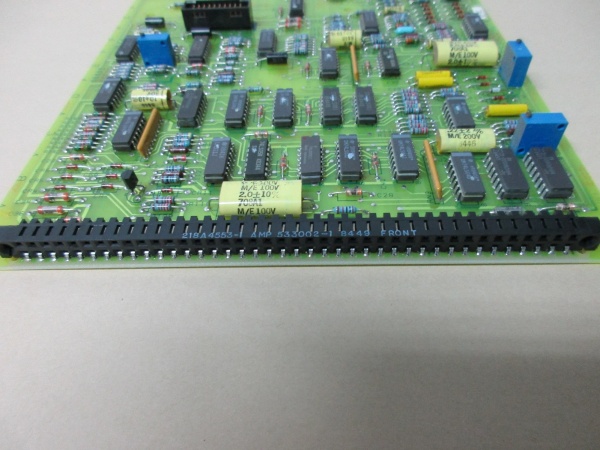

The board serves as a specialized gas turbine auxiliary interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this module provides the dedicated signal conditioning and interface logic required for gas turbine-specific auxiliary systems that differ from steam turbine or general industrial applications. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring that gas turbine-specific controls remain synchronized and fault-tolerant across redundant processing paths.

As a gas turbine auxiliary interface, the unit manages the unique requirements of gas turbine packages, including fuel forwarding system controls, turbine compartment ventilation, inlet air systems, and exhaust monitoring. It receives low-level signals from gas turbine sensors—such as fuel pressure transmitters, combustion temperature monitors, and vibration sensors—and conditions these signals for the Mark IV microprocessor-based control algorithms. Simultaneously, it outputs control commands to gas turbine actuators, valves, and motor controllers with the appropriate signal levels and timing sequences.

The board features EPROM-based firmware storage that contains gas-turbine-specific control algorithms, fuel scheduling maps, and protection logic tailored to heavy-duty frame turbines and aeroderivative units. Multiple trimmer potentiometers accessible from the front panel allow field calibration of sensor scaling, valve positioning, and control loop gains to match specific gas turbine configurations and site conditions.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture allows this specialized interface to operate autonomously while maintaining deterministic synchronization with the main control processors, ensuring that gas turbine auxiliary controls remain coordinated with turbine protection and sequencing logic.

DS3800NGTA1F1E

DS3800NGTA1F1E: Technical Specifications

-

Model Number: DS3800NGTA1F1E

-

Manufacturer: General Electric

-

Product Type: Gas Turbine Auxiliary Interface Board

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Function: Gas turbine-specific auxiliary I/O and signal conditioning

-

Memory: EPROM sockets for GT-specific firmware and calibration data

-

Field Calibration: Multiple trimmer potentiometers for sensor/actuator matching

-

Signal Conditioning: Analog and discrete I/O for fuel, cooling, and ventilation systems

-

Status Indication: Diagnostic LEDs for GT auxiliary system status

-

Backplane Interface: High-density modular connector (AMD 218A4553-1 compatible)

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Mounting: Standard Mark IV rack slot with integrated retention levers

-

Power Supply: Derived from Mark IV rack backplane (+5 VDC logic, ±15V analog)

Part 4: Core Features & Customer Value

Gas Turbine-Specific Signal Optimization: The board provides specialized signal conditioning tailored to the unique sensor types and actuators found in gas turbine applications. It handles the specific voltage levels, current loops, and timing requirements of fuel control valves, inlet guide vanes, and turbine compartment dampers that differ from steam turbine or general-purpose industrial equipment. For gas turbine operators, this specialization ensures reliable startup sequencing, fuel transfer operations, and compartment ventilation control optimized for the thermal and aerodynamic characteristics of gas turbines.

Field-Configurable for Diverse GT Applications: The combination of EPROM firmware and trimmer potentiometers allows the same hardware to support different gas turbine models—from heavy-duty Frame units to aeroderivative packages—through configuration rather than manufacturing variations. Technicians can adjust calibration for different fuel types (natural gas, distillate, dual-fuel), ambient conditions, or specific auxiliary equipment without replacing the board. This flexibility reduces spare parts inventory requirements for facilities operating multiple gas turbine models.

Robust Auxiliary System Integration: The board manages the complex interlocks and sequencing required for gas turbine auxiliary systems, ensuring that fuel forwarding pumps, compartment ventilation fans, and cooling systems operate in the correct order during startup and shutdown. It provides the logical interface between the Mark IV core control and package-specific equipment, isolating the main processors from the electrical noise and ground loops common in gas turbine auxiliary circuits.

Comprehensive Diagnostic Capabilities: Integrated diagnostics monitor sensor integrity, actuator response, and communication status for all gas turbine auxiliary channels. LEDs provide immediate indication of fuel system status, ventilation operation, or fault conditions without requiring diagnostic software. For maintenance technicians, this visibility enables rapid identification of whether issues originate in field sensors, actuator wiring, or the interface board itself, reducing troubleshooting time during critical startup activities.

Hot-Swappable Design for Availability: The board supports replacement within the Mark IV TMR architecture, allowing gas turbine auxiliary control functions to be maintained during single-channel maintenance. Given the critical nature of fuel and ventilation systems for gas turbine operation, this maintainability ensures that auxiliary control redundancy can be restored quickly without requiring turbine shutdown, supporting continuous operation in peaking or base-load applications.

DS3800NGTA1F1E

Part 5: Typical Applications

Heavy-Duty Gas Turbine Fuel System Control:

The DS3800NGTA1F1E is deployed in GE Frame 5, 6, 7, and 9 gas turbines to interface with fuel forwarding systems, fuel control valves, and fuel transfer equipment. In these applications, the board conditions signals from fuel pressure transmitters, temperature sensors, and flow meters while outputting control commands to fuel metering valves and shutoff valves. The trimmer potentiometers calibrate the analog interface for different fuel types and valve characteristics, ensuring precise fuel control during startup, load changes, and fuel transfer operations between gas and liquid fuels in dual-fuel units.

The DS3800NGTA1F1E is deployed in GE Frame 5, 6, 7, and 9 gas turbines to interface with fuel forwarding systems, fuel control valves, and fuel transfer equipment. In these applications, the board conditions signals from fuel pressure transmitters, temperature sensors, and flow meters while outputting control commands to fuel metering valves and shutoff valves. The trimmer potentiometers calibrate the analog interface for different fuel types and valve characteristics, ensuring precise fuel control during startup, load changes, and fuel transfer operations between gas and liquid fuels in dual-fuel units.

Gas Turbine Compartment Ventilation Management:

In gas turbine installations, the board controls compartment ventilation fans and dampers that manage the thermal environment and hazardous gas detection purge requirements. It monitors fan status, damper position, and compartment temperature sensors, implementing the ventilation sequencing required by NFPA codes and insurance requirements. The board ensures that ventilation is established before fuel is admitted to the turbine and maintains airflow during operation to prevent combustible gas accumulation.

In gas turbine installations, the board controls compartment ventilation fans and dampers that manage the thermal environment and hazardous gas detection purge requirements. It monitors fan status, damper position, and compartment temperature sensors, implementing the ventilation sequencing required by NFPA codes and insurance requirements. The board ensures that ventilation is established before fuel is admitted to the turbine and maintains airflow during operation to prevent combustible gas accumulation.

Inlet Air System Control:

For turbines equipped with inlet air conditioning—such as evaporative coolers, fogging systems, or inlet heating—the board manages the interface with these systems. It controls water injection valves, monitors inlet air temperature and humidity, and implements anti-icing control logic. The specialized signal conditioning handles the moisture-resistant sensors and high-humidity environments typical of inlet air systems, ensuring reliable operation in varying weather conditions.

For turbines equipped with inlet air conditioning—such as evaporative coolers, fogging systems, or inlet heating—the board manages the interface with these systems. It controls water injection valves, monitors inlet air temperature and humidity, and implements anti-icing control logic. The specialized signal conditioning handles the moisture-resistant sensors and high-humidity environments typical of inlet air systems, ensuring reliable operation in varying weather conditions.

Aeroderivative Package Auxiliary Control:

In LM6000 and LM2500 applications, the board manages the compact auxiliary systems typical of aeroderivative packages, including fuel forwarding skids, lube systems, and hydraulic control packages. It handles the faster response requirements and different scaling factors of aeroderivative controls compared to heavy-duty frames. The board’s configuration adapts to the specific packaging arrangements of these units, which often integrate auxiliaries more tightly with the turbine package than frame units.

In LM6000 and LM2500 applications, the board manages the compact auxiliary systems typical of aeroderivative packages, including fuel forwarding skids, lube systems, and hydraulic control packages. It handles the faster response requirements and different scaling factors of aeroderivative controls compared to heavy-duty frames. The board’s configuration adapts to the specific packaging arrangements of these units, which often integrate auxiliaries more tightly with the turbine package than frame units.

Exhaust and Emissions Monitoring Interface:

The board interfaces with exhaust gas temperature monitoring systems and emissions monitoring equipment (NOx, CO analyzers) required for environmental compliance. It conditions signals from high-temperature thermocouples in the exhaust path and communicates with continuous emissions monitoring systems. The board ensures that emissions data is reliably transmitted to the Mark IV data historian and that temperature monitoring protects against overtemperature conditions in the turbine hot gas path.

The board interfaces with exhaust gas temperature monitoring systems and emissions monitoring equipment (NOx, CO analyzers) required for environmental compliance. It conditions signals from high-temperature thermocouples in the exhaust path and communicates with continuous emissions monitoring systems. The board ensures that emissions data is reliably transmitted to the Mark IV data historian and that temperature monitoring protects against overtemperature conditions in the turbine hot gas path.