Description

DS3800NFMC1F Product Overview

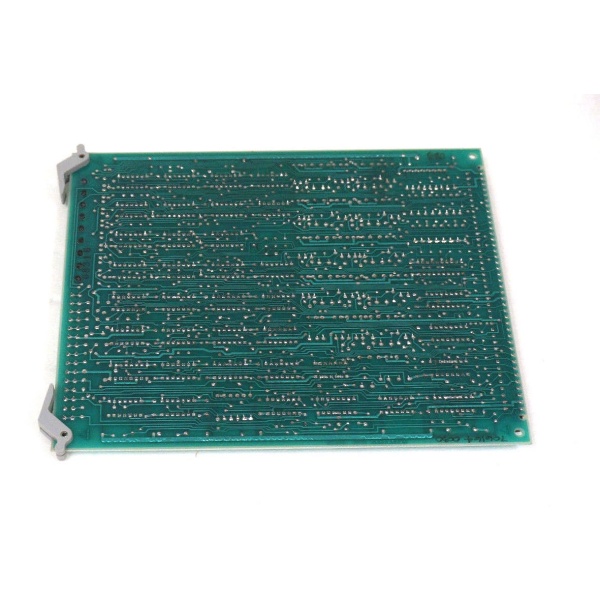

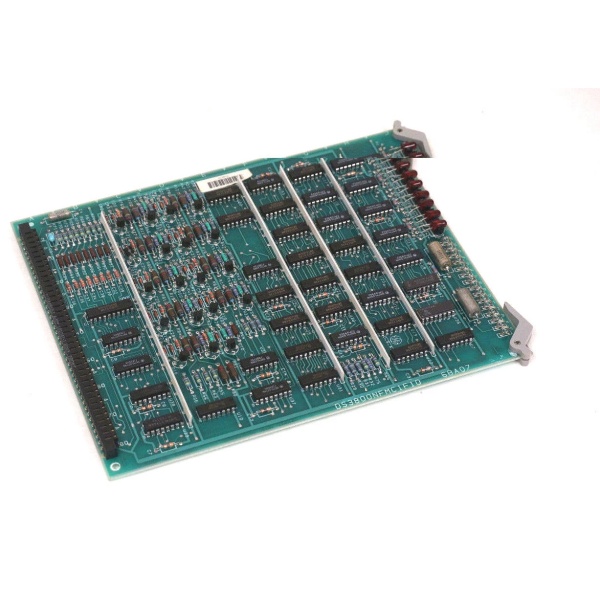

The DS3800NFMC1F is a field-control microprocessor board that resides in GE Mark IV and EX2000 turbine control racks. It plugs into the 6BA Euro-card file and acts as a distributed processing node: it runs local PID loops for field current or inlet-guide-vane position, scales bridge-voltage and current feedback, and reports status to the main CPU over the NDIA data bus. By off-loading the 2 ms regulation task from the central processor, the card ensures the exciter or fuel-valve loop remains deterministic even when the CPU is busy with sequencing or communications. All copper traces are encapsulated in high-temperature epoxy, making the unit non-repairable—any internal fault requires a complete card swap rather than component-level rework. The module is fully hot-swappable when the rack is powered down, and its low 12 W dissipation allows adjacent-slot population without additional cooling.

The DS3800NFMC1F is a field-control microprocessor board that resides in GE Mark IV and EX2000 turbine control racks. It plugs into the 6BA Euro-card file and acts as a distributed processing node: it runs local PID loops for field current or inlet-guide-vane position, scales bridge-voltage and current feedback, and reports status to the main CPU over the NDIA data bus. By off-loading the 2 ms regulation task from the central processor, the card ensures the exciter or fuel-valve loop remains deterministic even when the CPU is busy with sequencing or communications. All copper traces are encapsulated in high-temperature epoxy, making the unit non-repairable—any internal fault requires a complete card swap rather than component-level rework. The module is fully hot-swappable when the rack is powered down, and its low 12 W dissipation allows adjacent-slot population without additional cooling.

GE DS3800NFMC1F

DS3800NFMC1F Technical Specifications

-

Model Number: DS3800NFMC1F

-

Manufacturer: General Electric

-

Product Type: Field-Control Microprocessor / Auxiliary MPU Board

-

Series: DS3800, Mark IV / EX2000 Speedtronic

-

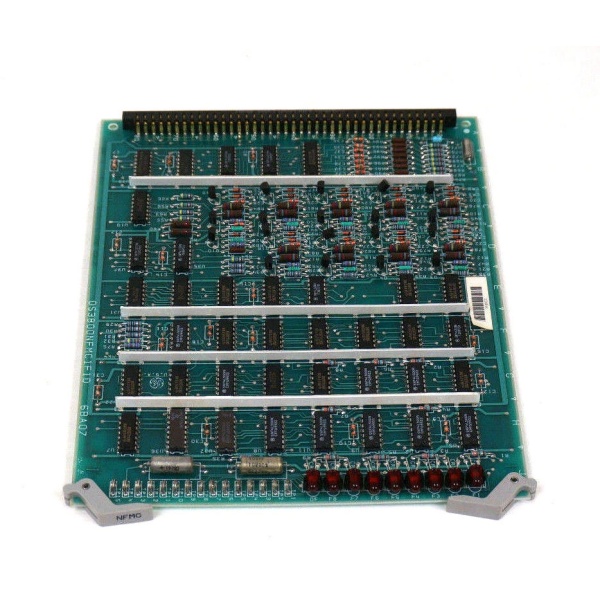

Form Factor: 6BA Euro-card (≈ 233 × 160 mm)

-

Back-Plane Connector: Dual 40-pin header (J1/J2)

-

Processor: Freescale 8349 @ 667 MHz (local PID execution)

-

Analog Inputs: 12 isolated channels (±10 V, 4–20 mA jumper-selectable)

-

Gate Drive Output: ±15 Vdc isolated, 2 A peak per SCR/IGBT leg

-

Power Demand: +5 V @ 1.2 A, ±15 V @ 0.3 A from rack 2PL bus

-

Isolation: 1500 Vdc channel-to-ground; 2.5 kV optical on gate fibers

-

Operating Temperature: 0 – 60 °C

-

Construction: Epoxy-sealed copper traces—non-repairable

Core Features & Customer Value

Distributed Processing: By embedding a 667 MHz Freescale core, the card executes the PID regulation loop locally. This guarantees the 2 ms control interval stays constant even when the central CPU is busy with sequencing or communications, giving the operator faster VAR response and tighter fuel-valve positioning during grid disturbances.

Epoxy-Sealed Construction: All internal copper is encapsulated in high-temperature epoxy. In environments with high humidity, dust, or conductive contamination the seal prevents trace-to-trace shorting that would otherwise cause random “FIELD MPU FAIL” alarms after ten-plus years of service. The trade-off is non-repairability—any internal fault requires a whole-card exchange—but this is offset by reduced troubleshooting time and the fact that plants stock one spare instead of maintaining a repair bench.

Wide Analog Window: The 12 input channels accept either ±10 V or 4–20 mA, jumper-selectable on the component side. This allows the same board to land bridge-voltage, field-current, or LVDT feedback without additional signal-conditioning modules, simplifying spare-parts inventory and reducing wiring errors during retrofit projects.

GE DS3800NFMC1F

Typical Applications

In combined-cycle plants the board is installed in the Mark IV exciter cubicle where it provides the local field-current regulator for the brushless exciter. During a black-start the card ramps field current from zero to rated value over a user-defined 30-second curve, preventing over-fluxing of the generator stator. The ±15 V gate-drive output fires the six-pulse SCR bridge directly, while the 12 analog inputs monitor bridge volts and armature current in real time.

On mechanical-drive gas compressors the same module is used to ramp inlet-guide-vane position. The local PID loop tracks the speed reference from the Mark IV CPU, ensuring the vanes move smoothly and avoid aerodynamic surge during rapid acceleration. Because the control algorithm runs locally, the card continues to regulate even if the main CPU is temporarily busy with communications or fault logging.