Description

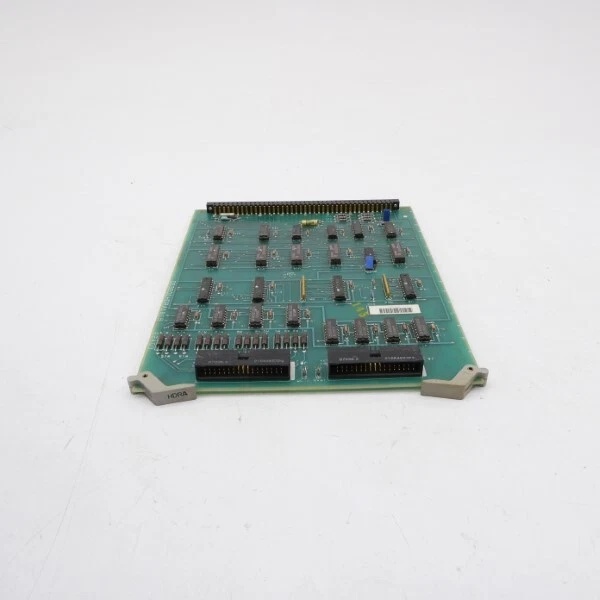

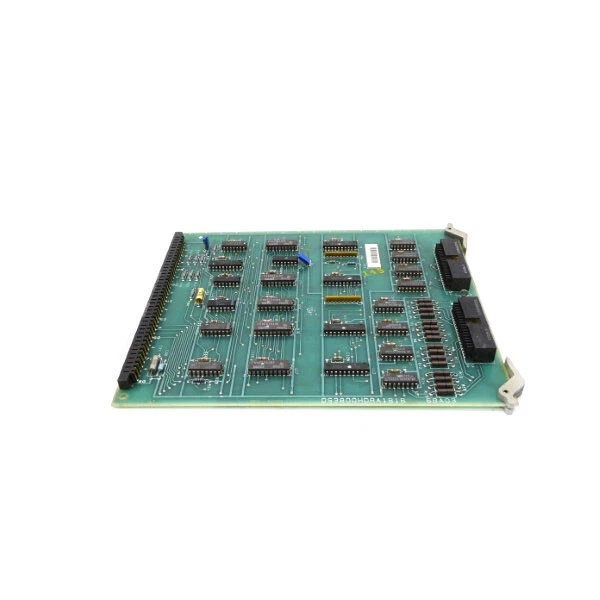

DS3800NFEE1C1B: Product Overview

The DS3800NFEE1C1B serves as a power conditioning and electromagnetic interference (EMI) filtering module within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this board receives raw DC power from the rack-level power supplies and performs final-stage regulation, filtering, and distribution to sensitive analog and digital circuits on adjacent I/O and processor boards. In the Mark IV’s triple modular redundant (TMR) system, this board ensures that each of the three independent control channels receives clean, stable power free from transients induced by field wiring or adjacent high-voltage equipment.

The board integrates multiple stages of filtering capacitors and ferrite EMI suppression components to attenuate high-frequency noise that can couple onto signal lines from variable frequency drives, ignition systems, or switchyard operations. This filtering is essential for maintaining the integrity of low-level analog signals (4-20mA, thermocouple millivolts) processed by the Mark IV’s control algorithms. The board also provides localized power storage through distributed capacitance, supplying brief ride-through capability during microseconds-level power disturbances.

As a member of the DS3800 series, the board operates within the Mark IV’s proven architecture deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s requirement for continuous availability in power generation applications necessitates that power conditioning components maintain specifications over extended thermal cycles and vibration environments typical of turbine control enclosures.

DS3800HDRA1B1B

DS3800NFEE1C1B: Technical Specifications

-

Model Number: DS3800NFEE1C1B

-

Manufacturer: General Electric

-

Product Type: Power Conditioning and EMI Filter Board

-

Series: GE Speedtronic Mark IV

-

Power Input: 24-125 VDC (via rack backplane)

-

Power Output: Multiple regulated DC rails for logic and analog circuits

-

EMI Filtering: Multi-stage common-mode and differential-mode filtering

-

Transient Protection: Metal oxide varistors (MOVs) and surge suppression diodes

-

Test Points: 12 TP test points (voltage monitoring locations)

-

Indicators: 2 LEDs (Power OK, Filter Active/Status)

-

Configuration: 2 jumpers (voltage range selection, testing mode)

-

Backplane Connector: High-density modular connector (AMD 218A4553-1 compatible)

-

Mounting: Factory-drilled corner holes with extraction levers

-

Operating Temperature: -40°C to +70°C (standard industrial grade)

-

Humidity: 5% to 95% non-condensing

-

Passive Components: Ceramic and tantalum capacitors, ferrite beads, metal film resistors

Part 4: Core Features & Customer Value

Clean Power Distribution for Signal Integrity: The primary function of this filtering board is to isolate sensitive Mark IV control circuits from power supply noise and transients. By providing localized EMI filtering at the board level rather than relying solely on rack-level power supplies, the board ensures that analog-to-digital converters and microprocessor logic receive stable reference voltages. For instrumentation engineers, this translates to consistent control loop performance without the drift or jitter caused by power supply noise, particularly critical when controlling fuel valves or generator excitation systems where millisecond timing precision affects turbine stability.

Field Diagnostics and Voltage Verification: With twelve strategically placed test points, technicians can verify all power rail voltages using standard multimeters without disturbing board connections. This accessibility is crucial during commissioning and troubleshooting, allowing quick verification that filtered outputs remain within the ±5% tolerance required by Mark IV specifications. The visible LED indicators provide immediate visual confirmation of power status and filter health, enabling operators to identify power anomalies during routine cabinet inspections without requiring diagnostic software connections.

Configurable Protection Schemes: The onboard jumpers allow field configuration of voltage ranges and test modes, accommodating different power system designs across the global Mark IV installed base. Whether the application utilizes 24 VDC, 48 VDC, or 125 VDC plant battery systems, the board can be configured to provide appropriate regulation and protection. This flexibility reduces spare parts inventory requirements, as the same board can support multiple plant voltage standards through simple hardware configuration rather than requiring model-specific variants.

Hot-Swappable Maintenance Design: The board integrates with the Mark IV TMR architecture to support online replacement procedures. When a power anomaly or filter degradation is detected, technicians can remove and replace the board while the redundant control channels maintain turbine protection. The high-density backplane connector ensures reliable power and ground connections through thousands of insertion cycles, while retention levers prevent vibration-induced loosening in environments subject to turbine operation harmonics.

DS3800HDRA1B1B

Part 5: Typical Applications

Gas Turbine Control System Power Conditioning:

The DS3800NFEE1C1B is commonly installed in GE Frame 5, 6, and 7 gas turbine Mark IV control cabinets to provide filtered power to vibration monitoring modules, temperature input cards, and servo valve driver circuits. In these applications, the board filters noise induced by the turbine’s high-voltage ignition exciters and variable frequency starter motors. The filtered power rails are essential for maintaining the precision of proximity probe measurements used for shaft vibration and thrust position monitoring, where microvolt-level signal integrity directly impacts machinery protection decisions.

The DS3800NFEE1C1B is commonly installed in GE Frame 5, 6, and 7 gas turbine Mark IV control cabinets to provide filtered power to vibration monitoring modules, temperature input cards, and servo valve driver circuits. In these applications, the board filters noise induced by the turbine’s high-voltage ignition exciters and variable frequency starter motors. The filtered power rails are essential for maintaining the precision of proximity probe measurements used for shaft vibration and thrust position monitoring, where microvolt-level signal integrity directly impacts machinery protection decisions.

Steam Turbine Electro-Hydraulic Control (EHC) Systems:

In steam turbine applications within paper mills, petrochemical facilities, and power plants, this board provides clean power to the analog servo circuits controlling steam admission valves. The EMI filtering prevents 60 Hz ground loop currents and harmonics from plant electrical distribution systems from coupling into the valve position feedback signals. During plant electrical disturbances or grid faults, the board’s transient suppression capabilities protect downstream logic components from voltage spikes that could otherwise force a turbine trip or damage expensive I/O modules.

In steam turbine applications within paper mills, petrochemical facilities, and power plants, this board provides clean power to the analog servo circuits controlling steam admission valves. The EMI filtering prevents 60 Hz ground loop currents and harmonics from plant electrical distribution systems from coupling into the valve position feedback signals. During plant electrical disturbances or grid faults, the board’s transient suppression capabilities protect downstream logic components from voltage spikes that could otherwise force a turbine trip or damage expensive I/O modules.

Combined-Cycle Plant Distributed I/O:

In combined-cycle power plants where the Mark IV controls interface with plant Distributed Control Systems (DCS) via serial communication links, the board filters power to communication interface modules. The isolation prevents ground potential differences between the turbine skid and control room from corrupting data transmissions. This is particularly critical during lightning storms or switching operations when transient ground voltage rises can otherwise interrupt the Modbus or proprietary GE communication protocols linking turbine controls with plant-wide automation systems.

In combined-cycle power plants where the Mark IV controls interface with plant Distributed Control Systems (DCS) via serial communication links, the board filters power to communication interface modules. The isolation prevents ground potential differences between the turbine skid and control room from corrupting data transmissions. This is particularly critical during lightning storms or switching operations when transient ground voltage rises can otherwise interrupt the Modbus or proprietary GE communication protocols linking turbine controls with plant-wide automation systems.

Emergency Shutdown and Protection Systems:

Within the Mark IV’s triple modular redundant safety architecture, this board supplies filtered power to the voting logic and trip relay driver circuits. The board’s high reliability ensures that protective functions—overspeed detection, over temperature protection, and vibration trip logic—remain powered during electrical transients that might otherwise reset or glitch safety systems. The 125 VDC battery-backed power systems common in power plants require the board’s filtering to prevent battery charger ripple from affecting sensitive trip comparators.

Within the Mark IV’s triple modular redundant safety architecture, this board supplies filtered power to the voting logic and trip relay driver circuits. The board’s high reliability ensures that protective functions—overspeed detection, over temperature protection, and vibration trip logic—remain powered during electrical transients that might otherwise reset or glitch safety systems. The 125 VDC battery-backed power systems common in power plants require the board’s filtering to prevent battery charger ripple from affecting sensitive trip comparators.