Description

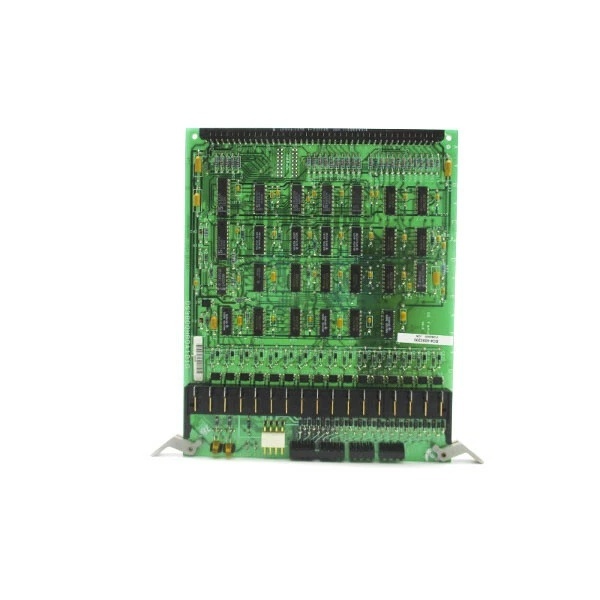

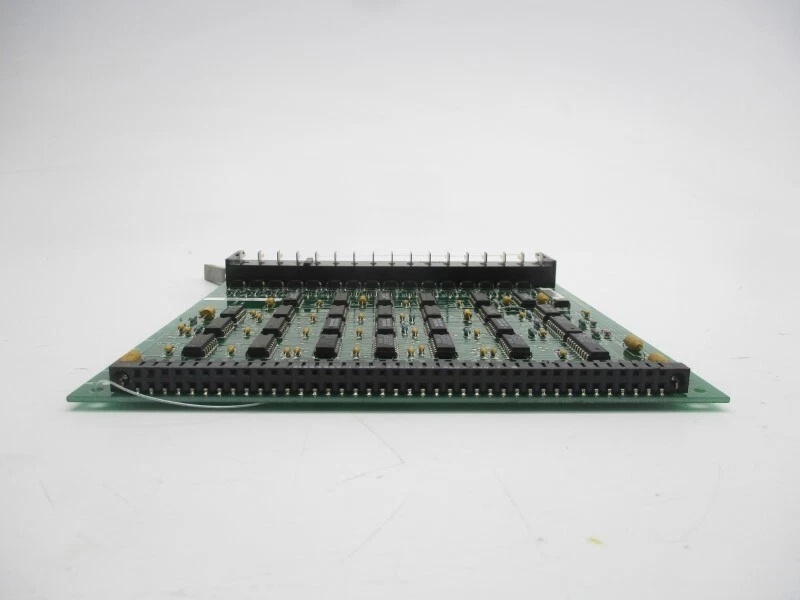

DS3800NFCD1K1E: Product Overview

The board serves as a precision firing circuit controller within the Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this unit generates the precisely timed gate pulses necessary to trigger power semiconductor devices in high voltage applications. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring synchronized thyristor firing for critical functions such as generator field excitation, static starter systems, and variable voltage auxiliary drives.

As a firing circuit module, the unit manages the conversion of digital firing angle commands from the microprocessor-based control algorithms into analog gate pulses that trigger SCRs at specific points in the AC waveform. This phase-angle control regulates power delivery to field windings and high horsepower auxiliary equipment, enabling smooth starting sequences and controlled acceleration of turbine-generator sets. The board incorporates high voltage isolation barriers that protect sensitive low voltage control electronics from the high potentials present on thyristor anode and cathode circuits.

The board features twelve independent firing channels capable of controlling multiple thyristor phases or redundant trigger circuits. EPROM-based firmware stores site-specific firing sequences, timing maps, and protection algorithms tailored to specific turbine models and power semiconductor configurations. Integrated metal oxide varistors and surge suppression components protect the firing circuits from voltage transients generated by line switching or load disturbances.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture requires deterministic microsecond-level timing precision for thyristor firing; this board provides the infrastructure necessary to maintain coordinated power control synchronized with turbine operational states.

GE DS3800HRDA1D1D

DS3800NFCD1K1E: Technical Specifications

-

Model Number: DS3800NFCD1K1E

-

Manufacturer: General Electric

-

Product Type: Firing Circuit Control Board

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Firing Channels: 12 independent gate pulse outputs

-

Semiconductor Interface: SCR/Thyristor gate control

-

Firing Mode: Phase-angle control with microsecond timing resolution

-

Isolation: High voltage galvanic isolation between control logic and gate drive circuits

-

Memory: EPROM sockets for firing sequence firmware and timing curves

-

Protection: Metal oxide varistors (MOVs) and surge suppression diodes

-

Status Indication: Diagnostic LEDs for firing activity and fault detection

-

Backplane Interface: High-density modular connector (AMD 218A4553-1 compatible)

-

Operating Temperature: -35°C to +45°C (critical thermal management range)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Mounting: Standard Mark IV rack slot with integrated retention levers

Part 4: Core Features & Customer Value

Precision Phase-Angle Firing Control: The board generates gate pulses with microsecond-level timing accuracy, enabling precise regulation of power semiconductor conduction. This precision is essential for generator field excitation systems where firing angle directly controls field current and generator terminal voltage. By controlling the exact point in the AC waveform where thyristors conduct, the board enables smooth, stepless voltage regulation from zero to full field current, eliminating mechanical wear associated with electromechanical regulator systems.

High Voltage Isolation and Safety: Integrated optocouplers or pulse transformers provide galvanic isolation between low voltage control logic and high voltage thyristor circuits that may operate at 125-750 volts. This isolation prevents catastrophic failure of control electronics during semiconductor faults or line transients, protecting expensive microprocessor boards from high voltage intrusion. For maintenance personnel, this isolation ensures safe troubleshooting procedures by maintaining electrical separation between control and power circuits.

Comprehensive Transient Protection: Metal oxide varistors and surge suppression components integrated into the firing circuits clamp voltage spikes caused by switching transients or load disturbances, preventing damage to sensitive gate drive electronics. This protection extends the operational life of the firing circuit components and reduces the frequency of board replacements in electrically noisy industrial environments where high voltage switching generates substantial transients.

Twelve-Channel Flexible Architecture: The twelve independent firing channels support complex multi-thyristor applications such as three-phase full wave rectifier bridges or multi-stage starter control systems. This channel density allows control of redundant trigger circuits or multiple independent power stages within a single board position, reducing rack space requirements and simplifying wiring in high component density applications.

EPROM-Based Firing Sequences: Firing algorithms, timing curves, and protection logic stored in non-volatile EPROM ensure consistent operational characteristics across power cycles and system restarts. Site-specific configurations for different turbine models or excitation system requirements can be implemented through firmware selection rather than hardware modifications, allowing standardized board inventory to support diverse applications through software configuration.

GE DS3800HRDA1D1D

Part 5: Typical Applications

Generator Static Excitation Systems:

The board is deployed in turbine-generator installations to control the thyristor bridges that supply DC field current to generator rotors. In these applications, the twelve channels typically control six thyristors arranged in a three-phase full wave bridge configuration, with redundant triggers for critical phases. The board receives firing angle commands from the automatic voltage regulator and generates precisely timed gate pulses to maintain generator terminal voltage within tight tolerances during grid parallel operation and load changes.

The board is deployed in turbine-generator installations to control the thyristor bridges that supply DC field current to generator rotors. In these applications, the twelve channels typically control six thyristors arranged in a three-phase full wave bridge configuration, with redundant triggers for critical phases. The board receives firing angle commands from the automatic voltage regulator and generates precisely timed gate pulses to maintain generator terminal voltage within tight tolerances during grid parallel operation and load changes.

Turbine Static Starting Systems:

For large gas turbines utilizing static frequency converters or wound rotor motor starters, this board manages the thyristor firing that controls starting torque and acceleration rates. The phase-angle firing gradually increases motor voltage during turbine roll-up, preventing mechanical shock to the compressor and turbine train. The twelve channels may control multiple stages of resistance switching or current limiting circuits, with EPROM-stored acceleration curves optimized for specific turbine inertia characteristics.

For large gas turbines utilizing static frequency converters or wound rotor motor starters, this board manages the thyristor firing that controls starting torque and acceleration rates. The phase-angle firing gradually increases motor voltage during turbine roll-up, preventing mechanical shock to the compressor and turbine train. The twelve channels may control multiple stages of resistance switching or current limiting circuits, with EPROM-stored acceleration curves optimized for specific turbine inertia characteristics.

High Voltage Auxiliary Drive Control:

In applications requiring precise speed control of large auxiliary motors such as boiler feed pumps or cooling fans, the board controls thyristor-based variable voltage drives. It manages the firing of power semiconductors in the armature circuit to provide smooth speed regulation without the harmonic distortion associated with modern PWM drives, making it suitable for sensitive auxiliaries where electrical noise must be minimized.

In applications requiring precise speed control of large auxiliary motors such as boiler feed pumps or cooling fans, the board controls thyristor-based variable voltage drives. It manages the firing of power semiconductors in the armature circuit to provide smooth speed regulation without the harmonic distortion associated with modern PWM drives, making it suitable for sensitive auxiliaries where electrical noise must be minimized.

Emergency and Backup Power Regulation:

The board manages field forcing and emergency excitation control during grid disturbances. When rapid increases in field current are required to maintain generator stability during faults, the firing circuit provides the fast response necessary to implement high field forcing within milliseconds. The redundant channel architecture ensures that emergency excitation capabilities remain available even during single-channel maintenance activities.

The board manages field forcing and emergency excitation control during grid disturbances. When rapid increases in field current are required to maintain generator stability during faults, the firing circuit provides the fast response necessary to implement high field forcing within milliseconds. The redundant channel architecture ensures that emergency excitation capabilities remain available even during single-channel maintenance activities.